Engineering design at Chambo Fisheries, the world’s largest biofloc tank farm for tilapia

Experience raising tilapia in biofloc technology (BFT), where aerial feeding rates are at least four to five orders of magnitude greater than in shrimp BFT systems, is limited. Areas that are particularly limited are knowledge systems centered on BFT engineering economics, tilapia feeding systems and bioenergetics, cost factors and the economics of this new technology relative to conventional tilapia aquaculture systems. Insightful experience gained at Chambo Fisheries in Malawi, Africa, and described here has helped fill many of these knowledge gaps.

Chambo Fisheries is purportedly the world’s largest tilapia BFT tank farm and the largest tank farm in Africa, located on the outskirts of Blantyre, Malawi. The farm became operational in 2013 based upon the mandatory production of Mozambique tilapia (O. mossambicus) and Shiranus tilapia (O. shiranus) due to restrictions that forbid the importation and culture of farmed breeds of Nile tilapia (O. niloticus) into the country.

Despite the slow growth in feral genes of O. mossambicus and O. shiranus compared to best farmed breeds of O. niloticus, several factors – including good flavor quality without purging, low Feed Conversion Ratios (FCRs), year-round production potential (on completion of the Shallow Solar Pond supplemental heating system) and favorable market factors in Malawi and regionally – make Chambo Fisheries potentially well poised for expansion.

The system architecture was originated by the author as the Chief Technical Officer of SustAqua Fish Farms (Pty) Ltd., which developed the farm blueprints, production schedules, management systems and executed start-up, monitoring and management training.

Vertically integrated farm design

Chambo Fisheries operates a vertically integrated farming operation that carries a quarantine facility, broodstock pairing tanks, an artificial incubation room for hatching eggs removed from female brooders, a dedicated nursery system, purging tanks, a moist feed milling plant and an ice plant and cold-storage facilities apart from the BFT grow-out tanks. Fig. 1 illustrates the farmed lifecycle of O. shiranus tilapia at Chambo Fisheries.

Shiranus tilapia reaches an average marketable weight of 218 grams in 189 days from hatching within a temperature range of 27 to 29 degrees-C. Although purging fish to improve flavor quality is practiced, it is unnecessary in well-managed BFT systems as the fish carry no objectionable flavor taints. Fish are sold whole on ice and no form of processing takes place on site.

The farm boasts eight large, Round-ended (R-ended) grow-out tanks having an effective rearing volume of 766,000 liters capable of producing up to 100 tons of tilapia per tank in a year, or up to 130 kilograms per cubic meter (kg/m3) per year via a multi-cohort, sequential, continuous production schedule, although rearing densities average only around 20 kg/m3 (Fig. 1). Management at Chambo Fisheries is presently targeting 80 tons per grow-out tank per year on the completion of the heating system hardware.

Due to the cooler climate at 1,130 meters above sea level in Blantyre, all production facilities required placement beneath greenhouse enclosures in addition to the need for supplemental heat sourced from Shallow Solar Ponds (SSP) coupled to a hydronic heating system, which includes stainless steel heat exchangers built into the tank floor and regulated by thermostatically actuated, heat exchanger pumps for heat transport.

Enhanced efficiency and productivity through engineering design and adopted stock management philosophy

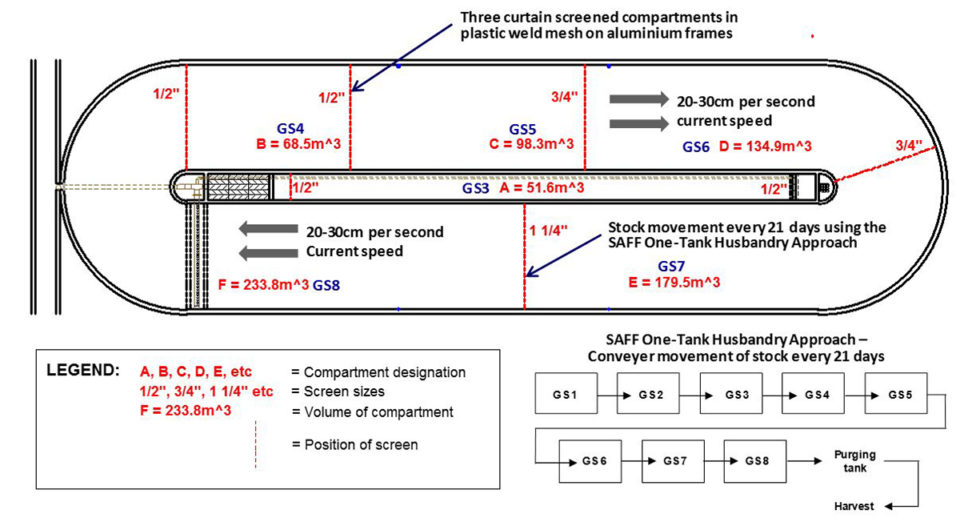

The farm design is tailored to take advantage of the benefits of continuous sequential production where each grow-out tank is stocked and harvested every three weeks. This stock management philosophy is enabled by the use of screened compartments (Fig. 3) in which fish are moved in a conveyor fashion every three week to a larger compartment via simple crowding screens and custom-developed seine nets.

This management technique elevates Production: Capacity ratios (P:C ratios) greatly from around 2.9 in a batch system to within a range of 5.5 to 6.2:1 yielding around 4.6-5.8 tons of market-ready fish every three weeks, or around 17 times a year, and greatly increases the crop turnover rate using O. niloticus for this illustration (Table 1 and Fig. 2).

The use of a sequential multi-cohort production system essentially increases production output by a factor of 2.5 and reduces input power costs by 60 percent when gauged against a batch production system yielding an effective P:C ratio of only 2.9:1. Viability is greatly enhanced due to the more than doubling of production output based upon the same investment in equipment and infrastructure compared to a batch production system. This unique innovation by SustAqua Fish Farms (SAFF) was first pioneered by the company in the Middle East on two RAS farms and a third RAS farm in Malawi and is called the SAFF One-Tank Husbandry Approach.

Kourie, BFT, Table 1

| Parameter/indicator | Batch | Multi-sequential | Advantages of multi-sequential over batch |

|---|---|---|---|

| Fish carrying capacity, tons of fish (to feed load capacity) | 13.89 | 16.61 | Higher feeding rate per unit biomass |

| Number of cohort throughputs per years, n | 2.897 | 17.4 | More frequent harvesting |

| Annual production, tons | 40 | 101 | 150.1% greater annual producion |

| Production: capacity ratio (P:C ratio) | 2.897 | 6.06 | 109.3% increase in P:C ratio |

| Annual yield, kg/m3 | 52.5 | 131.3 | 150.1% greater yield |

| Input power per unit fish production, kWh/kg | 4.24 | 1.70 | 60% power input savings |

| Feed load capacity utilization, % capacity (avg/max X 100) | 42.4 | 85.2 | 101.1% increased capacity utilization |

Every aspect of the BFT R-ended tank design aims to minimize both capital and operating costs taking full advantage of the superior hydraulic environment created by SAFF’s integrated R-ended tank design. The R-ended BFT grow-out tanks include a built-in lamella separator for solids capture and removal. Control over the concentration of floc in the water column and the retention time of fecal and organic material (dead material) is achieved by regulating the run-time and water flow rate through a lamella separator from a full width floor drain in the main tank. Water is pulled through the lamella separator by causing a head differential at the far end of the central channel by a multiple pod airlift pump, allowing for infinite control over the pumping rate.

One of the important provisos for the success of the continuous BFT culture tanks at Chambo Fisheries is ascribed to careful engineering design to prevent solid waste accumulation anywhere in the system, as well as the effective twice daily discharge of solids from the tanks at capacity.

Horizontal water velocity control in the range 15 to 30 centimeters per second creates a beneficial streaming effect by adjusting the depth of the paddles on the paddlewheel aerators to regulate horizontal trust to overcome frictional drag forces of the moving water mass in the tanks and through segmented screened compartments. This improves the driving concentration gradient for oxygen transfer of carefully selected and positioned aeration devices, consisting of four, full-width floor diffusers at strategic intervals along the length axis of the tanks as well as the two 10-Hp paddlewheel aerators.

Forced moderate exercise has been shown to induce muscle hypertrophy, improve growth rates and reduce the energetic costs of protein accretion. Here fed fish, even described in tilapias, under continuous moderate exercise conditions exhibit a shift in their metabolisms to derive energy for swimming activity and protein accretion largely from carbohydrates and lipids rather than protein (a survival mechanism to spare protein loss from the muscle). This results in fish at harvest which carry a lower fat content while Feed Conversion Ratios (FCRs) are reduced, growth is enhanced, meat texture is improved (firmer), and fillet yields are elevated marginally (more plump fish relative to their body lengths).

One of the concerns of BFT is the higher energy demands for mixing, aeration and horizontal water movement for solids transport to the waste drains. Regardless of the stock management philosophy, whether production originates from batch culture or sequential multi-cohort culture, both modes of operation require continuous mixing and aeration. The advantage of sequential multi-cohort production, apart from the increased crop turnover relative to carrying capacity, is the greatly improved energy efficiency. Table 1 indicates a power demand of 4.24 kWh/kg of biomass gain in a batch system versus just 1.7 kWh/kg under a sequential multi-cohort production system at sea-level. This result is quite comparable to unit power consumption in more efficient RAS systems raising tilapias.

In part 2 of this article, I will continue discussing the benefits of BFT as a competitive and sustainable alternative, low-cost, intensive feedlot technology for tilapia aquaculture.

Author

-

Ramon M. Kourie

Chief Technical Officer

SAFF - SustAqua Fish Farms (Pty) Ltd

14 Branch Lane, Blairgowrie, 2625

Johannesburg, South Africa

http://sustaquafishfarms.co.za

[97,122,46,111,99,46,115,109,114,97,102,104,115,105,102,97,117,113,97,116,115,117,115,64,101,105,114,117,111,107,110,111,109,97,114]

Tagged With

Related Posts

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Aquafeeds

Biofloc consumption by Pacific white shrimp postlarvae

The stable isotopes technique with δ13C and δ15N can be used to determine the relevance of different food sources to shrimp feeding during the pre-nursery phase of Litopenaeus vannamei culture. During this trial, different types of commercial feed, microalgae, Artemia sp. nauplii and bioflocs were used as food sources.

Intelligence

Biofloc technology production promising in temperate zones

A study was conducted to assess the feasibility to grow Channel catfish (Ictalurus punctatus) in an outdoor biofloc system during winter in a temperate zone. High biomasses of market-size channel catfish were successfully maintained through the winter with high survival and in good condition in both treatments.