Physical, position descriptions

Why do seafood buyers increasingly want written procedure manuals, quality systems, and biosecurity programs from seafood processors? They demand more because just having a hazard analysis critical control point (HACCP) plan is not enough to satisfy consumer worries about bio-terrorism, product quality and social issues

Burden on processors

The burden is on seafood processors to provide their clients with these written system manuals. The first step in creating the documentation is usually that of writing procedures manuals for every facet of plant operations: processing itself, maintenance activities, administrative functions, physical security operations, etc. This is a labor-intensive and time-consuming proposition, involving all members of the plant processing team – from maintenance to quality control personnel. Nonetheless, the benefits to plant operations make all the work worthwhile.

Ironically, for the most part, it is not the implementation of procedures that is difficult, as these are usually already implemented in processing plants. It takes time and work, however, to codify actual actions in a coherent, organized manual that is easily understood by both plant personnel and outside inspectors and auditors.

Once plant management has made the commitment to invest in the drafting of procedures manuals, it is important to identify personnel who can write them adequately. Do not expect this to be an easy or short-term job. Drafting a complete set of procedures manuals for all facets of plant operations will probably take six months to a year of intermittent effort on the part of designated personnel.

Management can hire an outside consultant to provide guidance on how to organize and carry out the process. But in general, in-house staff already familiar with plant procedures can more easily carry out the majority of the work.

Total procedures manuals

Total procedures manuals include descriptions of all actions that contribute to plant production. Such actions address maintenance (frequency of maintenance and repair procedures for each piece of equipment, specifications for lubricants and fuels), laboratory activities (test types and procedures, media used), administration (accounting, client relations, human resources) and security (physical arrangements, staff size and duties, equipment used, training). Explanations for every decision, every action should be as detailed as possible.

Sometimes the hardest part of manual development is getting it off the ground. Once the initial moves are made, however, writing the rest of the procedures manual, including details on quality and biosecurity programs, falls into place. The following first two steps help enormously when writing total procedures manuals.

Physical description

The first and easiest step in this process is preparing a description of the physical plant itself. Note the area of the buildings, equipment on hand (compressors, ice machines, vehicles, generators) and positioning of security fencing. Create a scale map of the plant within its own grounds and in relation to its neighbors.

The map should indicate the locations of raw materials reception areas, loading docks, security inspection areas, trash facilities, the motor pool, maintenance areas, water treatment areas, and administrative buildings, if separate from plant buildings. Most processors already have maps on hand, as many HACCP-regulating authorities require a map detailing distances between operations and public areas as part of HACCP plans.

Position descriptions

The next and more complicated job is making up a complete organization chart that shows all personnel in the plant. Making this out in one large format may be unwieldy, so it is easier to do in steps.

Start with the general manager and diagram all the division managers under his/her supervision: plant manager, operations manager, administrative manager, laboratory manager, quality control manager, etc. After that, break down each division into its own organization chart and list every position for each division. If there are five drivers with the same responsibilities, make one notation for drivers and add a “5” by the position name.

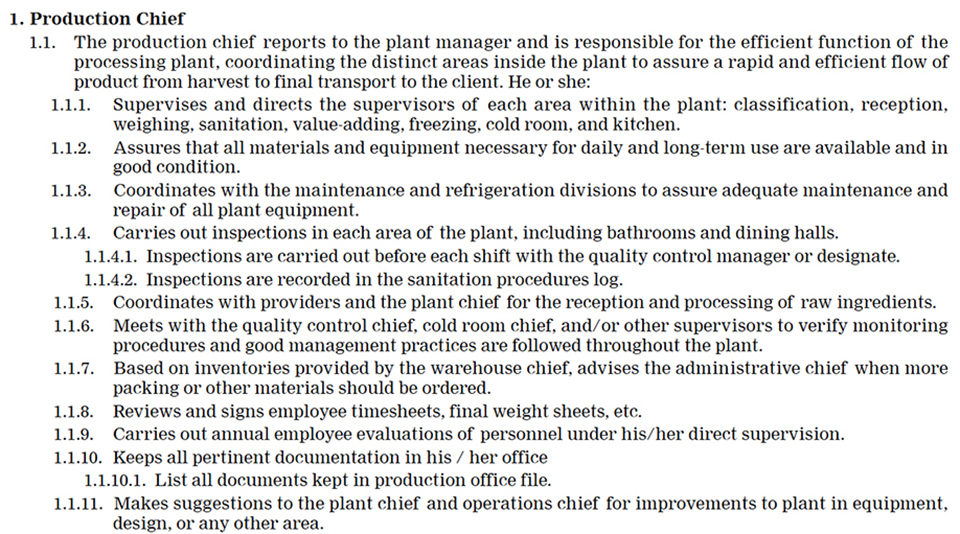

Once each position is identified, list the job responsibilities for each. It is extremely helpful to write this narrative in a bulleted format, listing each major responsibility with a number, letter, or bullet, and providing more detail in a subsection below the number. The completed responsibilities list should be extremely detailed (Fig. 1).

After the list of responsibilities is drafted, the involved staff should personally review the draft to ensure that all details have been captured correctly. Remember, this document should serve as a virtual photograph of plant operations for any inspector or auditor who wishes to read it. It’s important to get this right.

Effective management tool

Moreover, the exercise of making out in-depth narratives of all plant positions is a priceless tool for management that indicates where responsibilities and work lie. Sometimes, in large operations, it is easy to lose track of who is actually doing the work. Drafting accurate job descriptions is a wonderful diagnostic tool for managers, especially if it they are based on real investigation of the work each person does at the plant.

Accurate position descriptions can indicate areas that are overstaffed, or conversely, employees who are overburdened with responsibilities. They allow managers to make more informed personnel assignments, increasing efficiency and, in some cases, even reducing costs.

The process is also an enormous step forward toward drafting procedures, as many are addressed within the job responsibilities. Once the responsibilities are reviewed by personnel and found accurate and precise, seafood processors can begin drafting procedures for each area of their plants. Procedural documentation will be covered in subsequent articles.

Note: The author is an accredited Aquaculture Certification Council, Inc. certifier and author of HACCP and the Shrimp Farm, A Manual for Shrimp Farmers.

(Editor’s Note: This article was originally published in the April 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Intelligence

HACCP programs control antibiotic residues, other risks in aquaculture

Based on seven basic principles, HACCP plans identify critical control points and critical limits, and establish monitoring methods, record-keeping procedures and appropriate corrective actions.

Intelligence

4-hexylresorcinol: sulfite-free control for melanosis in crustaceans

4-hexylresorcinol in a nonsulfite processing treatment against melanosis in crustaceans inhibits natural enzymes for shell hardening.

Responsibility

Beyond HACCP: Total procedures manuals, Part 2

Detailing the HACCP procedures and specifications for every stage of production and processing in a total procedures manual is a hallmark of quality.

Responsibility

Beyond HACCP: Total procedures manuals, Part 3

Processors maintain facility and product security via HACCP procedures and supporting documentation that control physical security, employees and visitors.