Certain species and production systems will be exempt from limitations

The United States Environmental Protection Agency (EPA) recently published draft aquaculture effluent guidelines in the Federal Register (see http://www.epa.gov/fedrgstr/EPA-WATER/2002/September/Day-12/w21673.pdf).The final guidelines, which will be imposed on U.S. aquaculture activities in June 2004, are not expected to differ greatly from the proposed ones.

It is likely that U.S. regulations will serve as a reference for environmental agencies drafting aquaculture effluent regulations in other nations, as well as other international aquaculture bodies.

Pollution discharge elimination system

In 1973, EPA promulgated the National Pollution Discharge Elimination System (NPDES) permit application rules for Concentrated Aquatic Animal Production Facilities (CAAPF), but federal effluent guidelines were not developed for aquaculture. Nevertheless, since 1973, states could impose NPDES permits on CAAPF.

Coldwater CAAPF were defined as ponds, raceways, or similar structures that discharged at least 30 days/year, but did not include facilities that produced less than 9,090 harvest weight kg/year or 2,272 kg during the month of maximum feeding. Warmwater CAAPF were defined as ponds, raceways, or similar structures that discharged at least 30 days/year but did not include closed ponds that discharged only during periods of excess runoff or facilities that produced less than 45,454 harvest weight kg/year.

EPA reviewed these CAAPF definitions and decided to maintain them in the proposed effluent limitations guidelines for U.S. aquaculture. It is still not clear whether the definitions apply to a single hydrologic unit of ponds or other structures discharging at one point or a facility under common ownership or management.

Some species exempt

EPA decided also to exempt certain species and production systems from effluent limitations. These exemptions included crawfish, alligators, ponds, lobster pounds, molluscan shell-fish production in open water, aquariums, and Alaskan net pen systems for producing native species for restocking. The bases for the exemptions were:

- EPA does not believe the exempted species and production systems add more than trivial amounts of water pollutants.

- EPA does not believe control technologies to reduce pollutant loads from the exempted species and production systems in more than minimal amounts are feasible.

EPA spent about two years drafting the proposed guidelines. It made a thorough literature study, site visits, economic analyses, andeffluent analyses, and participated in several meetings with the aquaculture industry. The U.S. Department of Agriculture Joint Subcommittee on Aquaculture formed an Aquaculture Effluents Task Force, which provides industry input to EPA and maintains liaison with EPA officials for formulating responsible aquaculture effluent rules. Thus, the exemptions and proposed effluent limitations for nonexempted production systems were based upon a thorough evaluation of a large amount of information.

Proposed guidelines

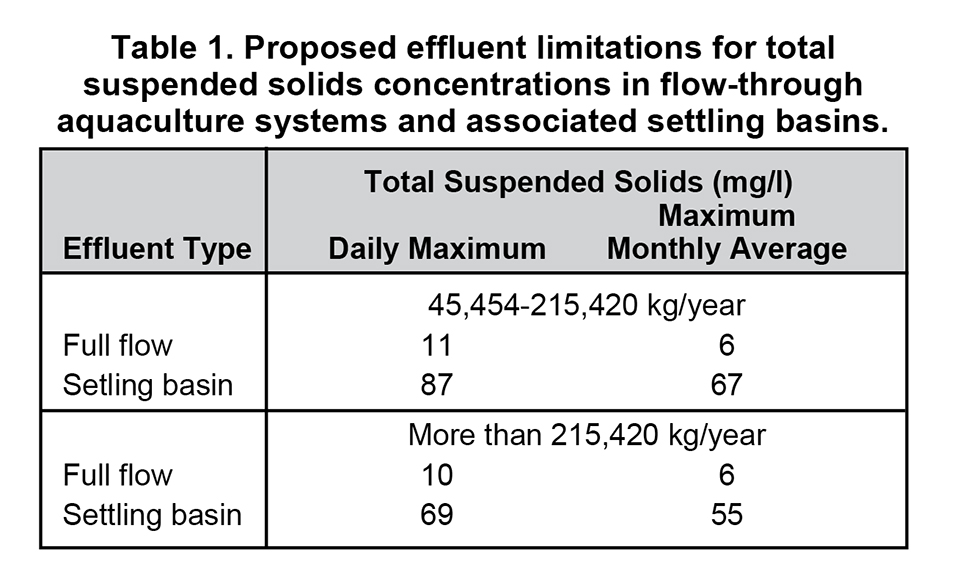

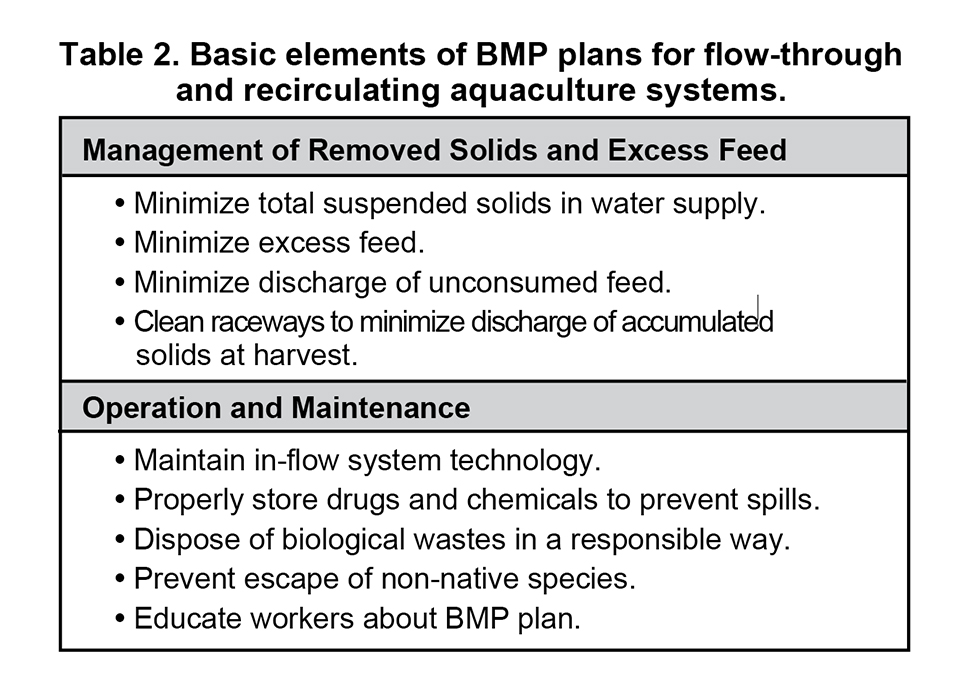

EPA proposes effluent guidelines for flow-through, recirculating, and net pen systems. For flow-through systems and offline settling basins for these systems, numerical limitations for total dissolved solids (TSS) will be required (Table 1). Moreover, a best management practices (BMP) plan must be prepared according to EPA specifications. The basic elements of the BMP plan are given in Table 2.

Recirculating systems

Effluent limitations for recirculating systems producing more than 45,454 harvest weight kg/year were proposed as follows:

- Maximum daily TSS: 50 mg/liter.

- Maximum monthly average TSS: 30 mg/liter.

- BMP plan for nonconventional and toxic pollutants.

- BMP plan for removed solids,excess feed, and operations and maintenance.

BMP plans for recirculating systems will have the same basic elements as those for flow-through systems.

Net pen systems

Net pen systems with harvest weights above 45,454 kg per year must be monitored for feed consumption to prevent feed from falling through the nets and accumulating beneath the pens. A BMP plan that prevents the escape of non-native species and minimizes the discharge of fish blood and tissue, solid wastes, cleaning chemicals, and materials containing tributyl tin compounds must be prepared.

Reporting drugs and chemicals

There also is a requirement to report all drug and chemical uses that do not comply with label directions and the use of investigational animal drugs. The reporting requirement also extends to the application of drugs in medicated feed.

Shrimp ponds

Shrimp ponds employing water exchange can qualify as CAAPF because they discharge more than 30 days a year. Some shrimp farms will be subject to NPDES permits if individual states decide to require effluent limitations for pond CAAPF. The effluent limitations for such pond systems would be established by the states, for the draft EPA document does not include suggested effluent guidelines for ponds.

BMP plans

In “Draft Guidance for Aquatic Animal Production Facilities to Assist in Reducing the Discharge of Pollutants,” (available at http://www.epa.gov/ost/guide/aquaculture/guidance/frontmatterandcontents.pdf), EPA discusses the use of BMP and the preparation of BMP plans. The suggested practices are similar to those recommended by the Global Aquaculture Alliance and other aquaculture organizations. EPA will suggest, but not require, that pond systems not subject to NPDES permits be operated according to best management practices in order to reduce the volume and improve the quality of pond effluents.

ACC standards

Aquaculture Certification Council, Inc. (ACC), a new international farm certification organization, requires certified shrimp farms, regardless of their annual production, to comply with effluent limitations for pH, total suspended solids, soluble phosphorus, total ammonia nitrogen, five-day biochemical oxygen demand, dissolved oxygen, and salinity. In addition, certified shrimp farms must employ BMP to comply with several other standards for environmental protection.

Environmental advocacy groups and consumers expect certified shrimp to be produced by methods that go beyond the minimum care necessary for compliance with legal requirements. The ACC standard for shrimp farm effluents certainly goes far beyond the EPA’s recommendations. The ACC effluent standard also is expected to be as strict as or stricter than effluent limitations for NPDES permits that may be imposed on shrimp farms by individual states.

(Editor’s Note: This article was originally published in the February 2003 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Professor, Department of Fisheries and Allied Aquacultures

Auburn University

Auburn, Alabama 36849 USA[117,100,101,46,110,114,117,98,117,97,64,49,101,99,100,121,111,98]

Tagged With

Related Posts

Health & Welfare

Ammonia toxicity degrades animal health, growth

Ammonia nitrogen occurs in aquaculture systems as a waste product of protein metabolism by aquatic animals and degradation of organic matter, or in nitrogen fertilizers. Exposure can reduce growth and increase susceptibility to diseases in aquatic species.

Responsibility

Carbon dioxide: Waste, nutrient

Carbon dioxide is both a nutrient and a waste product in aquaculture. Some pond managers feel that application of organic matter to provide additional carbon dioxide can reduce pH and control blue-green algae.

Responsibility

Aquaculture effluent partially replaces growing mix for plant production

Aquaculture effluent can be an effective fertilizer in land-based plant production. Research with tilapia utilized dewatered aquaculture effluent (A.E.) as a partial substrate replacement for tomato plant seedlings. Seedling growth decreased when effluent replaced a commercial growing mix at 25 percent or more.

Responsibility

Defining ranges for water quality variables presents complex, challenging process

The creation and application of reference tables for acceptable concentration ranges of physical and chemical water quality variables for culture organisms would be challenging due to the differing tolerances found among the many farmed species.