Temperatures ranging from 100 to 150 degrees-C did not negatively affect digestibility of macronutrients, amino acids

Extruded feeds differ from steam-pelleted feeds in their greater porosity, which aids in buoyancy control and in fat absorption capacity. High-energy fish diets generally rely on extrusion processing, because steam-pelleted diets cannot absorb more than 17 to 20 percent fat. However, extruded feeds are exposed to higher levels of temperature, pressure, and shear than steam-pelleted feeds. This study was undertaken to determine if extrusion temperatures negatively affect digestibility of nutrients in feed.

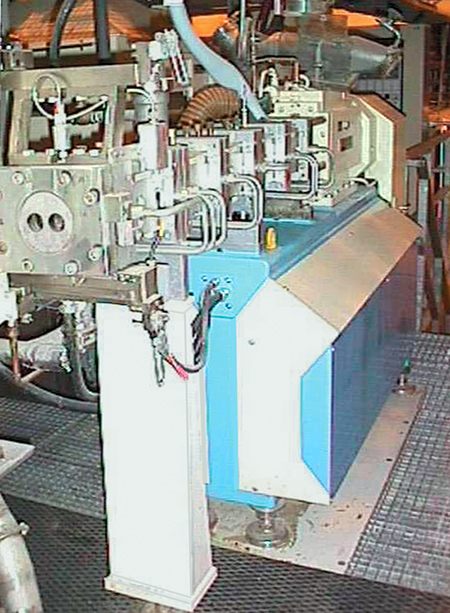

Extrusion process

Extrusion processing of feed is a multifunctional operation with several factors affecting product characteristics. After milling, batching and mixing, the dry ingredients are heated in the pre-conditioner by contact with water and steam under constant mixing before entering the extruder. The extruder barrel is a tube with rotating screw(s) enclosed. In the extruder, necessary pressure is created to force the moistened feed-blend through an orifice, which gives the desired shape to the product.

Extruders used for food and feed production normally are high-temperature and short-time (HTST) cookers. When leaving the extruder, the feed is normally dried by hot air before fat can be added in a vacuum coater. Then the feed is cooled, bagged and shipped.

Nutritional impacts of extrusion process

The time during which feed mash is exposed for heating during processing (pre-conditioning and extrusion) is normally less than five minutes. High moisture content combined with short duration of exposure implies that extrusion may not be detrimental to the feed’s nutritional value. However, the feed mash undergoes significant changes during processing as it is heated, kneaded and sheared, suggesting that extrusion is not neutral to the nutritive value of the feed.

Starch gelatinization

When the feed mash is exposed to heat and moisture, starch undergoes gelatinization, which aids in pellet binding and is important for the physical quality of the feed. Furthermore, digestibility of starch is highly affected by the physical state of the starch. Several carnivorous fish species, such as rainbow trout and Atlantic salmon, have low activity of amylase and are inefficient at digesting raw starch. Hydrolysis of starch is largely caused by intestinal disaccharidases. Thus, proper gelatinization is important to make the starch available for the digestive enzymes in the fish. To make high energy feeds, a highly expanded, porous feed is required so that fat added after extrusion is absorbed and remains inside the pellet until fish eats the feed. Proper gelatinization of starch evokes expansion as the feed is forced through the die.

Protein denaturing

The heat in the process also causes melting and denaturing of proteins, important for pellet binding. Mild heat treatment may improve the nutritional value of protein ingredients, because denaturing exposes new sites for digestive enzymes to attack and might make the protein easier to digest. Furthermore, heat is known to inactivate heat-labile, anti-nutritional factors occurring in vegetable ingredients, like protease inhibitors and lectins in soy.

Extrusion temperature, nutritive value of diet

Extrusion facilitates a wide range of temperature treatments, from less than 90 degrees-C up to more than 150 degrees-C. We have examined effects of extrusion temperature on digestibility and utilization of the diets by rainbow trout in two different experiments. In the first experiment a fishmeal-based diet was extruded with a twin-screw extruder at three temperatures (100, 125 and 150 degrees-C) on each of two production days. In the second experiment, another fishmeal-based diet was extruded using a single screw extruder at two temperatures (100 and 140 degrees-C).

The results showed that digestibility of protein, individual amino acids and energy were not significantly affected by extrusion temperature in either of the two experiments. Similarly, growth rates, feed conversion, and net accumulation efficiency (retention) of protein and energy were not significantly different in trout fed diets extruded at 100 and 140 degrees-C. In the first experiment, factors other than temperature in pre-conditioning and extrusion differed between the two production days.

These factors included conditioning temperature, feeding rate, moisture content of the extrudate, screw speed, and torque and pressure measured behind the die. Several of these factors may influence the nutritional value of the feed, and accordingly, digestibility of cysteine differed significantly between the two feed production days. Several previous studies have shown that digestibility of cysteine is sensitive to changes in feed and ingredient processing. Thus, the results indicate that other processing factors affected the nutritive value of a trout feed more than an increase in extruder temperature from 100 to 150 degrees-C.

Conclusion

During the process of extrusion, the blend of ingredients is exposed to elevated temperature, pressure, and shear. This study showed that extrusion processing with temperatures in the range from 100 to 150 degrees-C did not negatively affect digestibility of macronutrients or individual amino acids in rainbow trout.

(Editor’s Note: This article was originally published in the October 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Mette Sørensen

AKVAFORSK

Institute of Aquaculture Research

Ås, Norway[111,110,46,104,108,110,46,107,115,114,111,102,97,118,107,97,64,110,101,115,110,101,114,111,115,46,101,116,116,101,109]

-

Trond Storebakken

AKVAFORSK

Institute of Aquaculture Research

Ås, Norway