Poor yields at the Great Salt Lake, record low production

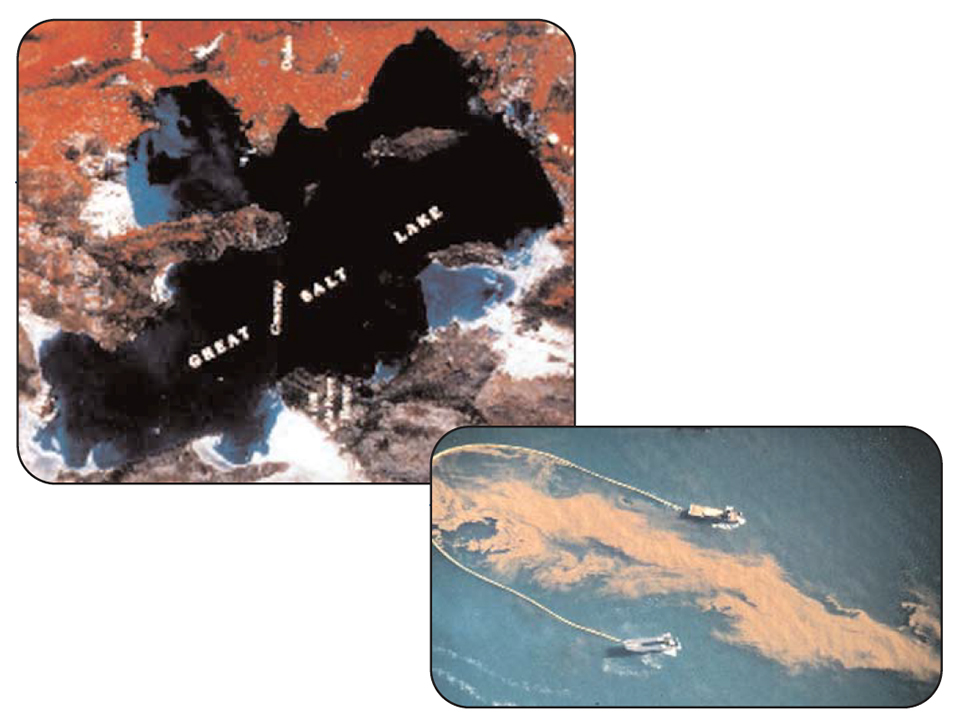

The Great Salt Lake in Utah, USA (GSL), a remainder of the Pleistocene Lake Bonneville, consists of two bodies separated by an East- West causeway, creating a southern arm and a northern arm (see satellite photo). GSL has been the principal source of artemia cysts to world aquaculture markets for the past 25 years. However, for a number of years now the salinity of its brine has been in a state of steady decline. This has affected the ecology of the lake, including its major inhabitant, the brine shrimp artemia.

The major problems in artemia production began after the very intense El Niño phenomenon from 1982 to 1984, when extraordinary snow pack and rainfall raised the lake level by 12 feet to an all-time record elevation of 4,212 feet. Because of the resulting drop in salinity, the artemia harvests between 1983 and 1990 took place primarily on the North arm, where the salinity was highest. After the historic lake high in 1987, six years of decline in lake elevation kept the salinity in ranges suitable for artemia cyst production. However, since the 1993-1994 harvest season the recent El Niño phenomenon added four feet of water to bring the lake to its present level of 4203 feet.

The current salinity of the South arm of the lake is in the 70 to 80 parts per thousand (ppt) range, while the northern arm is at saturation. Optimal salinity for artemia production is about 150 ppt. As the salinity continues to decline, the brine shrimp industry has been faced with a drastic decline in harvest figures. Moreover, a much higher percentage of artemia empty shells and lysed cysts have been gathering, which has decreased recovery yields to one half and even to one third.

The harvest goal for the 1999-2000 season that is underway today at the GSL is a compromise between the Industry and the Division of Wildlife Resources (DWR), which controls the exploitation of the GSL resource. In view of the GSL condition, DWR was considering not opening the season at all. In a September 1999 emergency meeting between the industry and the DWR, a compromise was reached to allow harvesting from the North arm. The continued rise in lake elevation has allowed a small artemia population to become established in the north arm, with some cyst production. Although the harvesting is still underway as this is written, the quantities being harvested are small and are said to constitute a record low. Total GSL harvest will not even satisfy 20 percent of global demand, and previous year’s stocks already have been sold.

The situation at the Great Salt Lake has been a major burden to the brine shrimp industry. Before this crisis, close to 40 companies where fishing the lake with a fleet in excess of 200 boats. Several harvesting companies have gone out of business, and many of the remaining players have formed alliances in an effort to reduce harvesting costs. One main alliance consists of the following groups: INVE Aquaculture Inc., Inland Sea, Golden West, Prime, Avocet, Sanders, Diversified Technologies, Bonneville Artemia, and Artemia of Utah. Another alliance is formed around the Salt Creek company. The allied companies cooperate at the level of harvesting and processing while in most cases keeping their own marketing and commercial strategies and channels.

New harvesting regions being developed

Since 1994, the INVE Group invested significantly in a development program for diversifying its artemia resources, by exploring and setting up new artemia exploitation areas in China and several Central- Asian countries. Today, still more sites are being developed to assure a sustainable supply of artemia cysts to the aquaculture industry. But despite these efforts, the supply of artemia cysts can hardly meet the demand of the rapidly growing aquaculture industry. Because of higher costs and limits in supply, the price of artemia is getting close to the record price levels of 1995-1996. This is driving the aquaculture industry toward optimizing the use of available artemia cysts and finding appropriate complementary products to substitute for part of the demand.

Recommendations for artemia use and substitution

The effort to develop complete substitutes for artemia has been extensive and is still ongoing. Although 100 percent replacement of artemia is possible, it is always at the cost of culture time, yield, and/or health condition of the cultured animals, which eventually affects farm economics and sustainability. A fast, realistic and beneficial approach today is the implementation of a number of procedures which focus on (1) a more efficient use of the available artemia and (2) greater use of partial replacement diets of artemia.

More efficient use of available live artemia

Standard operating procedures. Following guidelines (proper levels of temperature, pH, cyst density, etc.) for optimal hatching and storage of artemia can greatly improve production and storage of energy-rich instar I artemia nauplii. For example, harvest of instar I (with an extensive yolk reserve) rather than instar II/III nauplii, can avoid the loss of up to 39 percent of available energy. These guidelines are well documented in publications of the Laboratory for Aquaculture and artemia Reference Center (University Of Ghent, Belgium).

With the recent, more extensive use of artemia cysts from various origins, the hatching time and synchrony of every batch should be studied carefully along with hatching yield. artemia cysts with a wide hatching synchrony should be harvested in two or more steps in order to profit from their full instar I nutrient potential. Request such information from your artemia cyst supplier.

Enrichment of artemia and prolonged enrichment. Enrichment of artemia with HUFAs and other elements not only provides for a living capsule to transfer essential nutrients to the cultured animals, but also results in a larger and more energy-rich artemia. Standard enrichment procedures (48 hours) result in an average of 30 percent increase in artemia biomass.

In practice, this means that by applying the enrichment procedure one can still feed the same amount of artemia biomass while hatching 30 percent less artemia cysts. While today artemia enrichment is standard procedure in most marine fish hatcheries the world over, its application is still limited in shrimp culture. The main reason is that the effect of HUFA-boosting, although clearly visible in fish culture, has been inconsistent in industrial shrimp nursing.

However, given the potential to increase available artemia biomass and energy, enrichment should be reconsidered by the shrimp nursing sector as a means of reducing the amount of artemia cyst used. Artemia biomass can be increased by 50 percent when one goes beyond the present standard procedures and enriches artemia for 72 hours. This will further reduce the number of artemia required while still maintaining the same amount of artemia biomass.

Use of on-grown artemia. At present the technical procedures for superintensive production of ongrown artemia and related enrichment techniques have been proven feasible. However, their widespread application is limited because of the unbalanced economics in a number of regions, and more importantly, because of the potential risk for contamination.

Replacement of live artemia off-the-shelf diets

During the mid-1980’s, several microencapsulated, microparticulated, and flake diets were developed to partially replace or supplement Artemia. The degree of effective artemia substitution is a function of the nutritional and physico-chemical characteristics of the diets, culture techniques, and price of artemia cysts. Today one should focus on making the most out of dry diets in order to effectively substitute artemia nauplii. Note that quality differences between different feed products will obviously become more significant when substituting artemia at higher levels.

In shrimp nursing, a 50 percent effective substitution of artemia biomass by dry diets can be implemented in most existing systems. When going beyond this replacement rate, some of the present culture systems require minor adaptations to either feed management or tank hydraulics. In many marine fish nursing operations, the consumption of artemia cysts can be reduced effectively by more than half, provided one installs optimal weaning strategies applying artemia replacement and weaning diets in combination with proper water treatment and tank hydraulics. The yield using these procedures also relies on the implementation of quality feeding programs throughout the entire life cycle, i.e. from broodstock to grow-out transfer. The design of such sound feed management systems with appropriate feeds and feeding technologies adapted to various local conditions is destined to gain importance in the immediate future.

Replace artemia with artemia. Non-hatching decapsulated cysts, although in the category of off-the-shelf diets, deserve a special mention in the present framework. Their nutrient composition is similar to that of instar I artemia nauplii, but their energy content can be up to 50 percent higher. The energy consumed during the hatching process is still untouched in the deshelled embryos. Non-hatching decapsulated cysts can be applied in the same way as most dry diets and have proven to be a good alternative for live artemia nauplii in the diet of penaeid shrimp postlarvae. However, one should be cautious in using decapsulated cysts produced from old cysts, as they may have consumed most of their energy over time.

Following recent research on the “Live Food Factor” that indicates a beneficial impact of certain factors (nutritional, chemical) present in live feed on the ingestion, digestion and assimilation of artificial diets, special emphasis should also be placed on artemia-based diets. It is assumed that part of the beneficial biochemical aspects of feeding live nauplii remain valid in diet combinations which consist of a large percentage (> 50 percent) of artemia.

Rotifers. Rotifers are used extensively during the pre-artemia stages in fry production of marine fish. Although rotifers were used in the early days of penaeid shrimp culture, the practice was abandoned later in favor of the easier manipulation and higher food value of artemia nauplii.

In fish fry production, it used to be standard practice to feed rotifers up to day 35, followed by a 35- to 40-day feeding period with artemia prior to weaning on dry diets. Following the same tendency as in shrimp fry production, over the years the industry has reduced the rotifer feeding period with the introduction of artemia at an early age – day 14.

The advantages were obvious: (1) reduced dependence on rotifer cultures, including reduced labor cost, culture volume space, and risk of collapsed and contaminated cultures; and (2) higher food value of artemia nauplii. Today, thanks to tremendous developments in both the nutritional and zootechnical aspects of rotifer culture, high density populations can be grown and maintained with the desired nutritional profile, with minimal requirements of space, manpower and production time. Following well designed standard operating procedures for rotifer production, a daily adequate supply can be guaranteed. Moreover, using the appropriate culture and enrichment diets, rotifers today can compete with Artemia nauplii in terms of food value and hygienics.

The above arguments enable fish culturists to safely reduce the artemia feeding stage in favor of feeding rotifers. Provided the appropriate culture and feed management systems are applied, this step can be taken without any losses with regard to culture efficiency and yield. The same argument goes for the re-introduction of rotifers in shrimp culture. The present rotifer technology package allows for a simple, easy and safe implementation of a rotifer culture program in shrimp nurseries where artemia can be replaced effectively during late zoea, mysis and early PL stages.

Other zooplankton. The replacement of artemia with zooplankton (copepods, Daphnia, Moina, etc.) collected from poorly controlled sources has occasionally been practiced. Although the nutritive quality of these crustaceans can be very good, their inconsistent supply, and more importantly the risk of infections, may not favor them as a sustainable alternative today.

(Editor’s Note: This article was originally published in the December 1999 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Philippe Leger

INVE

[101,98,46,101,118,110,105,64,118,110,95,101,118,110,105]

Tagged With

Related Posts

Health & Welfare

Artemia bioencapsulation delivers probiotics via digestive tracts of fish larvae

Research with sturgeon and carp species indicated that encapsulated artemia has high potential to carry probiotics or other beneficial microorganisms.

Aquafeeds

Global brine shrimp supply a potential bottleneck to aquaculture expansion, part 1

The brine shrimp artemia is critical for larval fish and shrimp diets. As aquaculture expands, an effective artificial replacement diet for artemia is a major consideration for the industry.

Aquafeeds

Is a ‘baby food’ bottleneck looming for aquaculture?

Global aquaculture, particularly farmed shrimp, depends on artemia for hatchery feeds. Supplies meet current needs, but growth will require alternatives.

Innovation & Investment

Artemia, the ‘magic powder’ fueling a multi-billion-dollar industry

Artemia, microscopic brine shrimp used as feed in hatcheries, are the unsung heroes of aquaculture. Experts say artemia is still inspiring innovation more than 50 years after initial commercialization. These creatures are much more than Sea-Monkeys.