Reverse the course: Separate symptoms from practices where better management can be applied

Small-scale semi-intensive pond farming of tilapia in sub-Saharan Africa (SSA) is beset with low annual productivity in the range of 1,000 (or less) to 3,000 kg/hectare, with the typical reports skewed toward the low end of this range.

Experimental studies routinely document that a lot more tilapia could be produced in these systems without aeration, just by adhering to better management practices. The low productivity, coupled with a high cost of labor and feed in most SSA countries, leads to low profitability, which is considered nearly synonymous with low productivity when discussed in the SSA context.

No one disputes the facts of low productivity and profitability of pond-based tilapia farming in the region, yet there is plenty of debate regarding the causes and how to overcome them. In this article, I argue that many of the reasons proffered by professionals for the low productivity are valid. There is no single explanation for the problem; consequently, only by comprehensively examining the causes and how they interact can we develop effective solutions.

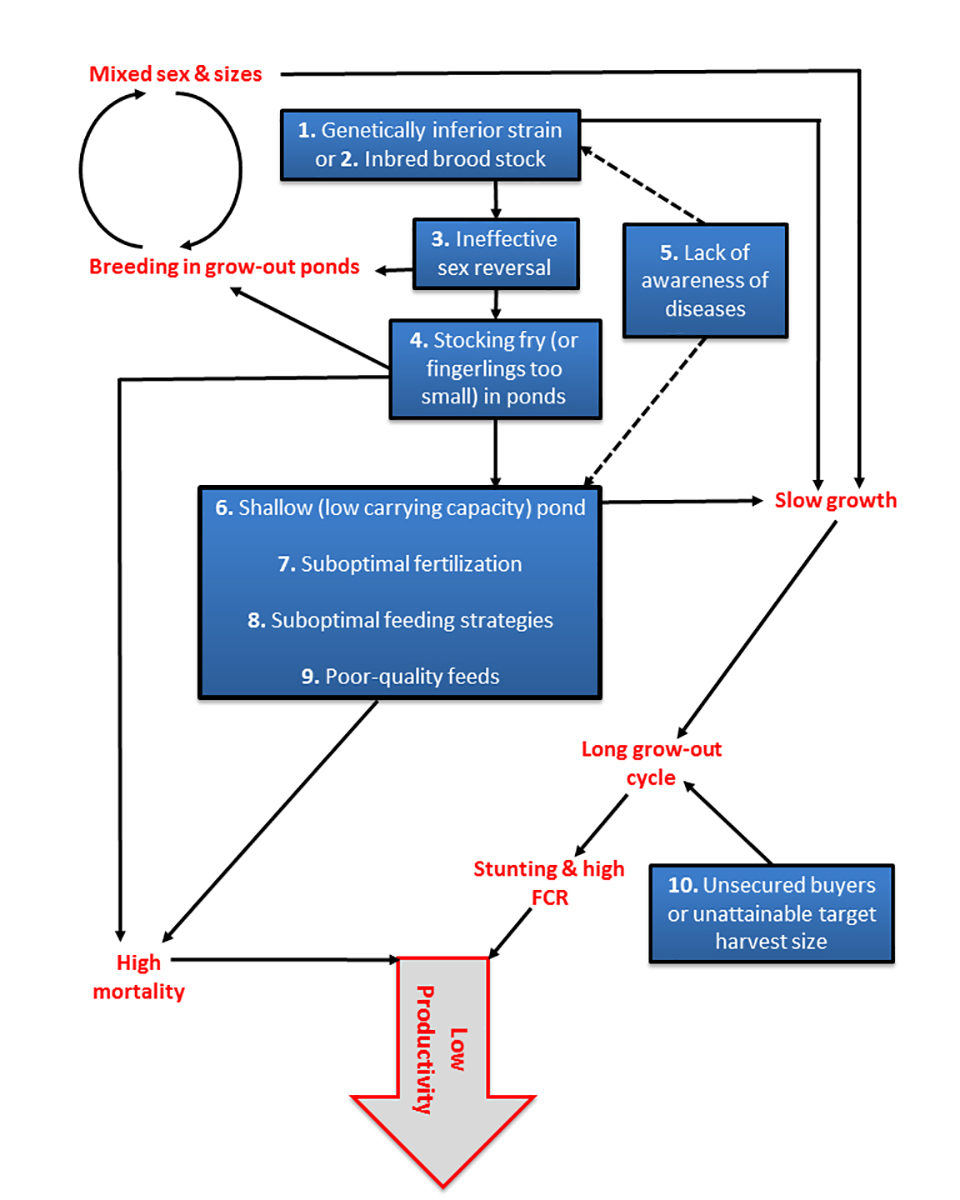

Drawing on my experiences in several SSA countries, particularly Ghana, I have tried to simplify the issues in a single chart (Fig. 1), separating the practices or root causes for which interventions in the form of better management practices can be applied (numbered 1 to 10 in blue boxes) from the consequences or symptoms of the practices.

Symptoms cannot be changed directly. By following the paths to low productivity in the diagram, it becomes obvious that 1) we often wrongly focus our concerns on symptoms (e.g., slow growth or high mortality); and 2) although a marginal increase may result, dealing with one or a few of the root causes of low productivity does not guarantee that productivity and profitability will increase substantially.

A brief discussion of each of the root causes of low productivity and profitability of pond-based tilapia farming in sub-Saharan Africa will form the basis of my prescription of how to reverse the course and lead to higher productivity and profitability.

1-2: Genetically inferior strains, poor broodstock management and inbreeding

The majority of tilapia farmers in SSA grow Nile tilapia (Oreochromis niloticus) for reasons that are technical, historical and part of the legacy of the policies of development partners that have operated in the region. The selection and breeding of tilapia strains for culture in SSA, however, has not followed a smooth or well documented process: There are currently as many policies and processes as there are countries.

But one common feature is the proliferation of wild, mixed, unknown and inferior strains of tilapia that grow slower and attain asymptotic size of 250 to 500 grams, only about one-third to one-half the size of the genetically improved farmed tilapia (GIFT) strains of O. niloticus grown in Asia, particularly in China. Fish will only grow up to their genetic potential under the best of culture conditions. Therefore, the only way to grow much bigger or faster growing tilapia as aspired to by many farmers is to begin with a stock of the best strain.

Closely associated with the problem of inferior strains is broodstock mismanagement. Many hatcheries and farms are managed by people with limited or no training in genetics or fish breeding. If at all attempted, selective breeding is done in a rudimentary fashion, by retaining the largest individuals of one generation and using them as breeders for the next, rapidly moving toward severe inbreeding of a stock that was probably a small number to begin with.

The result of inbreeding depression is slow growth. Even high performing strains can be rendered similarly ineffective by poor brood management and haphazard selective breeding. A better approach to ensure high-quality seed at the start of each production cycle is to leave selective breeding to the trained professionals and obtain fresh fingerlings or broodstock from certified hatcheries.

3-4: Ineffective sex-reversal and stocking fry or small fingerlings in grow-out ponds

Although technologies for all-male tilapia production, through hormonal sex-reversal or by other means, have been perfected for decades, there is little to no evidence that their use has permeated small-scale pond production systems in SSA. Where demand is high the situation is exacerbated by the pressure on outgrowers to procure fry (e.g., 1 to 2 grams) instead of larger fingerlings.

Whenever I have observed purportedly all-male fry or small fingerlings in ponds in Ghana to sizes at which tilapia sexes are identifiable, 7 to 30 percent of fingerlings have been female! At failure rates approaching 1 in 10 fingerlings as female at best, production might as well be considered mixed sex. Uncontrollable in-pond breeding and mixed sizes result from such situations and further depress growth.

Ironically, slow growth motivates longer grow-out cycles for farmers who assume that fish will continue to grow if they are kept longer in the pond, which create opportunity for multiple generations of tilapia to exist in the same pond with inconsistent production outcomes. Fry and smaller fingerlings are supposed to be cheaper but cost is indirectly incurred in their higher natural and handling mortality, in addition to having to feed a more expensive starter feed and a higher chance of females that may be ultimately discarded.

A better management practice is to raise fry or fingerlings in hapas sited within the ponds to the size where the sexes can be identified but not large enough to reproduce, and then sort by size and sex for stocking. Under water conditions of 27 to 30 degrees-C, 2-gram fry of the Akosombo (Volta) strain of Nile tilapia, fed high-quality starter feed at 10 percent body weight in green water, will attain 30 grams in 6 to 8 weeks, at which time male and females can be identified.

It is a tedious process for large farms to sort tilapia sexes manually, but for the majority of pond farms that are only a fraction of a hectare, this step is feasible and cost-saving. The main experience needed is the ability to identify tilapia sexes, a skill for which farmers can be trained with a relatively high degree of success.

5: Disease

One of the advantages of low intensity pond-based farming is the relatively low incidence of diseases. In fact, it is not widely verified that disease-driven mortality in ponds is significant in SSA compared to predatory pests such as bull frogs, snakes and birds, other fish including larger tilapia, poor water quality, or just high natural mortality of fry stocked very small.

Nevertheless, some farmers report increasingly high mortality in ponds and in the mix of possible causes is disease. Disease agents may be tracked into ponds through broodstock, fingerlings, the sources of pond water, or other pond inputs such as feed. Good pond preparation including drying and sanitizing helps but a major origin of diseases is uncontrolled introduction of aquatic animals (alive or dead) bypassing quarantine measures. Effective oversight of introductions and importations and certification of hatcheries is a vital role of government in the public interest.

6-9: Shallow ponds, inadequate feeds and suboptimal feeding and fertilization strategies

Next to the fish themselves, the pond environment and its management (i.e., fertilization, feeding, and water quality maintenance) greatly impact fish health, growth and productivity. The dosing of lime, fertilizer and other pond inputs is frequently based on surface area of a pond with the implicit assumption that the pond water is approximately 1 to 1.5 meters deep.

Observations in Ghana, however, have revealed that 80 percent or more of ponds are less than 1 meter deep and the average water depth of small-scale tilapia ponds is less than half a meter. Carrying capacity of shallower ponds is proportionally smaller, temperature swings through the day can be very extreme, and dosing of inputs can be off by significant margins. All these factors would lead to unstable water environment, reduced growth and mortalities.

Various combinations of green water production and supplementary feeding technologies continue to be shown as cost-saving alternatives to complete feeding. Yet, excessive feeding of expensive high-protein feeds to Nile tilapia is pervasive among farmers in SSA who can afford the feed.

On the flipside the common, less expensive, home-made powdery or sinking pellets that disintegrate quickly in water go to create more water quality problems in ponds than they serve as direct feed to fish. The cumulative result in these ponds regardless of the genetic potential of the fish stocked is slow growth and high mortality.

Standards of pond construction and maintenance need to be widely improved in SSA, with particular attention to appropriate pond depth. They should be drainable, regardless of pond size. Use recommended fertilization to grow fish largely on green water up to 100 to 150 grams and remaining grow-out should be based on low-protein feeds (e.g., 25 percent) and other techniques such as alternate-day feeding.

Observe fish and do not feed if fish are not feeding. These fertilization and feeding strategies may require a little more time to reach an ultimate size of about 250 to 300 grams, compared to full-ration commercial feeds but is well worth the cost savings.

10: Lack of market

Market is the only one of the 10 root causes of low productivity and profitability that the farmer does not control. It is advised to not site a farm or start production without knowing your market. Sadly, too may small-scale fish farmers in SSA have adopted fish farming initially through development aid programs that promoted subsistence farming; location of farms has therefore not considered market as a significant factor.

Farmers’ objectives invariably evolve over time toward financial profitability. In Ghana, over the last decade, pond-based farmers have chased the mirage of growing large tilapia, 400 grams or bigger, for restaurants, hotels and urban food joints, a niche already filled by cage farms and importers of whole frozen tilapia. In an attempt to achieve large sizes, fish are held in ponds for long periods (eight to nine months or longer) and of course those sizes are never achieved. Holding and feeding fish when they are not growing escalates FCR and adds to production cost.

Stocked at the right size, tilapia fingerlings will achieve most of their growth in less than six months. In most of warm SSA, at least two production cycles per year is feasible at a harvest size of 250 to 300 grams, with improved FCR. At these sizes, a higher stocking density can be used to boost production in a finite pond volume (i.e., productivity).

Egypt and Bangladesh produce large volumes of Nile tilapia that are harvested at 250 to 300 grams. The key to their success is efficiency in volume, not the size of the individual fish. On market, target the right rural, local and suburban consumers who will accept the size of fish you can grow and also do not plan to look for buyers only after the crop is ready.

Lastly, I emphasize the importance of good record keeping at both the farm and state level. Methods used to estimate productivity of small-scale farms in SSA by national extension services need to be more thorough and transparent. It may well be that data inaccuracies and data recycling contribute to the general perception of low productivity of tilapia ponds in sub-Saharan Africa. To the extent that productivity and profitability are truly low, better management practices can help to a large extent to reverse the course.

Author

-

Emmanuel A. Frimpong, Ph.D.

Virginia Tech

Department of Fish & Wildlife Conservation,

310 West Campus Drive

Blacksburg, VA 24061 USA

Related Posts

Innovation & Investment

Investing in Africa’s aquaculture future, part 1

What is the future that Africa wants? Views on how to grow aquaculture on the continent vary widely, but no one disputes the notion that food security, food safety, income generation and job creation all stand to benefit.

Innovation & Investment

Large-scale tilapia project driving aquaculture development in Ivory Coast

A large-scale aquaculture project in Ivory Coast, with "soft technology" adopted by Societe d’Elevage et de Distribution de Poissons, allows the full growing cycle to be controlled using local materials, manpower and inputs.

Health & Welfare

A look at tilapia aquaculture in Ghana

Aquaculture in Ghana has overcome its historic fits and starts and is helping to narrow the gap between domestic seafood production and consumption. Production is based on Nile tilapia.

Health & Welfare

Applied commercial breeding program for Nile tilapia in Egypt

A major goal of selective breeding program for Nile tilapia (Oreochromis niloticus) in Egypt is to select for fillet color and fillet weight in response to consumer preferences.