Plug flow and mixed flow depend on the paddle geometry, shaft speed, degree of fill

Preconditioning is commonly used in both pelleting and extrusion processing of aquatic feeds. In the preconditioning process, low-pressure steam and heat increase the moisture of the feed meal. In the pelleting process, the maximum moisture that can be attained without plugging the pellet mill is 17 percent. In contrast, moisture can be 20 percent in extrusion, and if forced into the extruder, even higher.

Extrusion is more flexible than pelleting in the amount of water it can handle, making it easier to raise the meal moisture and degree of cooking to the desired levels. Therefore, preconditioners are designed differently depending on the manufacturing process.

Understanding preconditioning

To understand the preconditioning process it is important to understand the heat and mass transfer between the components: steam and meal mixture. Steam transfers energy to the meal particles via condensation. Since the particles are colder than the steam, steam condenses on them and forms a thin film of water. Surrounded by saturated steam, meal particles increase in temperature and moisture.

The speed of heat and moisture uptake depends on two factors. The first is the film resistance at the surface of the particles. The more solid-to-fluid contact, the lower the film resistance. In other words, the more the material is exposed to the steam, the more contact between particles occurs. This can be accomplished by proper mixing in the preconditioner.

The second factor is how fast heat and moisture travel to the interior of the particles of mash meal, which is governed by Fourier’s and Fick’s second laws. The meal is composed of particles that have different internal resistance for heat and moisture. Therefore, by knowing the coefficients of diffusivity, one can apply physical laws to estimate the right preconditioner residence time to heat and humidify the particles homogeneously. In general, the higher the heat and water diffusivity, the faster heat and moisture flow into feed particles.

Starch

Most aquatic feeds have high amounts of wheat flour or wheat byproducts, of which starch is a major component. At ambient temperature, starch has a thermal diffusivity coefficient of 10-7 square meters per second. In contrast, water diffusivity is 10-5 square meters per second – 100 times less than that of starch. In simple words, heat transfer is faster than moisture internalization.

In most preconditioning situations, it is possible to heat meal to a target temperature, but then it takes longer to also increase the mash moisture. The latter is one of the reasons it is important to have adequate residence time in the preconditioner to allow moisture to penetrate the particles. Moisture and temperature are key elements for attaining high water stability in finished feeds.

Another important aspect in aquatic feeds is the hydration of other particles, in particular, the protein fraction in wheat known as gluten. Composed of two protein fractions, gluten requires hydration and mixing to form the gluten matrix.

In most cases, wheat gluten is considered the best natural binder when proper hydration and mixing are provided. In most single-pass conditioners, it is basically impossible to provide adequate mixing to sufficiently expose particles to steam or stimulate gluten matrix formation.

Film resistance

Film resistance around particles can be measured using the dimensionless Biot number. When resistance is in the film around particles, as is the case with preconditioners with poor mixing, the Biot number is less than 0.1. In conditioners with good mixing action, the main resistance is the diffusion of water to the particles, and the Biot number is greater than 10.

Film resistance around particles can be measured using the dimensionless Biot number. When resistance is in the film around particles, as is the case with preconditioners with poor mixing, the Biot number is less than 0.1. In conditioners with good mixing action, the main resistance is the diffusion of water to the particles, and the Biot number is greater than 10.

Based on this number, most preconditioners available today for pelleting can be classified into an intermediate category in mixing efficiency where the Biot number is approximately 1. The film and internal resistance have a direct impact on the rate of hydration into the particles.

Particle size, hydration

Ingredient particle size has a major impact on the rate of hydration in preconditioners. Particles larger than 400 μ require twice as much hydration time than particles smaller than 200 μ. The following formula, based on particle radius, is used to calculate the time required to hydrate particles.

As particle radius increases, a longer time is required for hydration. Thus, particles not only need to be small enough to improve feed digesti-bility, but also to improve hydration that can lead to higher water stability of the aquafeed. If particles are of uniform dimensions, the hydration rate will be similar in most particles. This is another good reason for considering postgrinding to achieve uniform particle size, and hence better hydration rates in mixers and preconditioners.

Residence time distribution

Residence time distribution (RTD) should not be confused with residence time. The latter can be determined by noting the time it takes a color marker to show at the exit of the preconditioner. RTD, the average time material stays in the preconditioner, has a characteristic bell-shaped curve. The shorter the distribution, the more uniform and efficient the preconditioner is in hydrating and heating particles uniformly.

There are two types of mixing in preconditioners. One is axial mixing, which increases the contact between particles and the steam/fluid in the preconditioning chamber. The second is radial mixing, which also affects particle/fluid contact, but depends more on shaft rotational speed and paddle configuration/geometry.

Depending on their designs, preconditioners can exhibit a plug flow with very little mixing and mixed flow with highly axial mixing. These flows depend on the paddle geometry, shaft speed, and degree of fill of the preconditioners’ designs.

Uneven coloration

A common problem during the pelleting of shrimp feeds is the appearance of unevenly colored pellets. In most cases, this is caused by inadequate moisture distribution in the preconditioner.

This can be easily explained by understanding RTD. In this case, the RTD is broad, meaning that some particles spend a short time in the preconditioner and thus receive insufficient moisture. This problem is not only associated with inadequate paddle configuration, shaft speed, or degree of fill, but also uneven particle size. Even if a preconditioner is properly optimized, a broad particle distribution size can result in uneven moisture distribution among particles. The large ones will have less moisture, while small ones have higher moisture content. Therefore, particle size needs to be as uniform as possible, and RTD needs to be as narrow as possible.

Fill ratio

Fill ratio represents the volume occupied by the meal in relation to the total volume of the preconditioner. Most preconditioners used in the pelleting industry today have low fill ratios below 30 percent. Small fill ratios mean preconditioners have more empty space.

Since steam is a gas, it tends to fill the voids in preconditioners. When this happens, less steam contacts the mix to heat and hydrate it. Therefore, increasing the fill ratio improves not only the residence time but also the temperature and hydration uniformity of the mix.

The degree of fill can be improved by properly adjusting the paddle angle. Twist paddles can increase axial mixing. In contrast, paddles placed at 180 degrees can increase the filling ratio. Most preconditioners are have paddles that can be adjusted by the operator.

In most cases, a good paddle configuration includes paddles in the reverse, some forward, and some flat. Some preconditioners also incorporate retention plates that provide an obstacle at the end of the unit and thus increase residence time.

New preconditioners

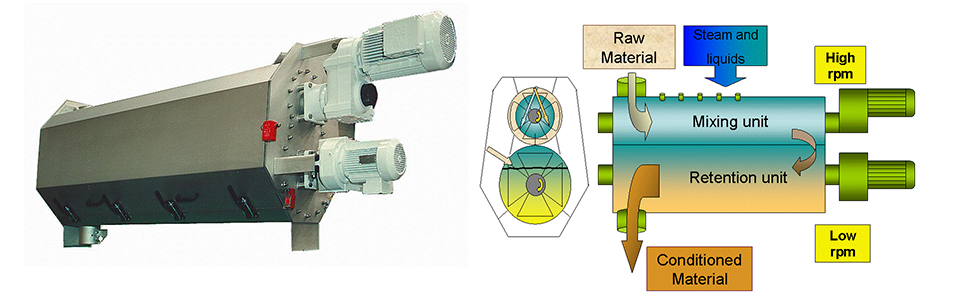

In the last two years, new preconditioners have been introduced to the market, and older versions have been improved. Most incorporate the aspects discussed above, including increased degree of fill, narrower RTD, and improved axial and radial mixing. One new preconditioner incorporates a high radial mixing in a small chamber where steam and water are injected. In a second chamber, more axial mixing occurs and the meal is allowed to hydrate.

This preconditioner was developed for extruders. To date, no one has used a preconditioner designed for an extruder in a pelleting machine, where it could very well be adapted to produce high-quality shrimp feeds. It would be interesting to compare the efficiency of one of these preconditioners used in conjunction with a pelleting line with the more traditional, low-fill capacity preconditioners often used today.

(Editor’s Note: This article was originally published in the December 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Eugenio Bortone, Ph.D., PAS, Dpl. ACAN

1521 Country Club Drive

Red Bay, Alabama 35582 USA

Tagged With

Related Posts

Aquafeeds

Preconditioning is crucial in aquafeed manufacturing

Preconditioning is an important step in the manufacturing of aquafeeds, because it increases the moisture content and temperature of ingredient meal particles, which is key to reach a high water stability desired in aquafeeds. Pre-conditioner efficiency requires consistent particle size and adequate mixing, residence time and fill ratio.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Least-cost formulation software in shrimp aquafeed production

The use of properly and efficiently formulated feeds using least-cost formulation software is an important determinant of a successful crop.