Underwater microphones monitor key environmental parameters, deliver alarms

In intensive farming systems for chickens, pigs, lot-fed cattle and sea cage salmon, feeding control systems reflect fundamental production technology. These systems use micro tag readers, infrared sensors, cameras and other sensing methods to automatically deliver an optimum ration to the animals every day.

Shrimp farming, however, faces a variety of unique challenges to implementing such feeding controls. Shrimp are small animals that weigh less than 50 grams. They are grown in large numbers up to several million in ponds with areas up to 20 hectares (ha) that have turbid waters that limit visual inspection. Counting and therefore biomass estimation can be very difficult.

Feeding trays

After the pioneer years, when feeding strategies were based on individual feed intake measurements in laboratory experiments, the use of feeding trays represented a significant advance in improving feed conversion in small, as well as large ponds. Nevertheless, the implementation and daily use of feed trays bring an increased need for skilled labor and subjective feed tray analysis, which is a measurement of feed intake with an inherent lag that can lead to waste.

Automatic feeders without sensor-based control technology have become popular in Thailand and Malaysia. The feeders do contribute to lower labor costs and, for some diligent operators, lower feed-conversion ratios (FCRs), but they are still fully dependent on human decisions based on feeding tray readings and weekly growth sampling.

In the last five years, a passive acoustic feeding-control technology has been developed by AQ1 Systems. The sound feeding system enables sensor-based control through technology that has been commercially validated at shrimp farms with different species in different countries.

Sound-based technology

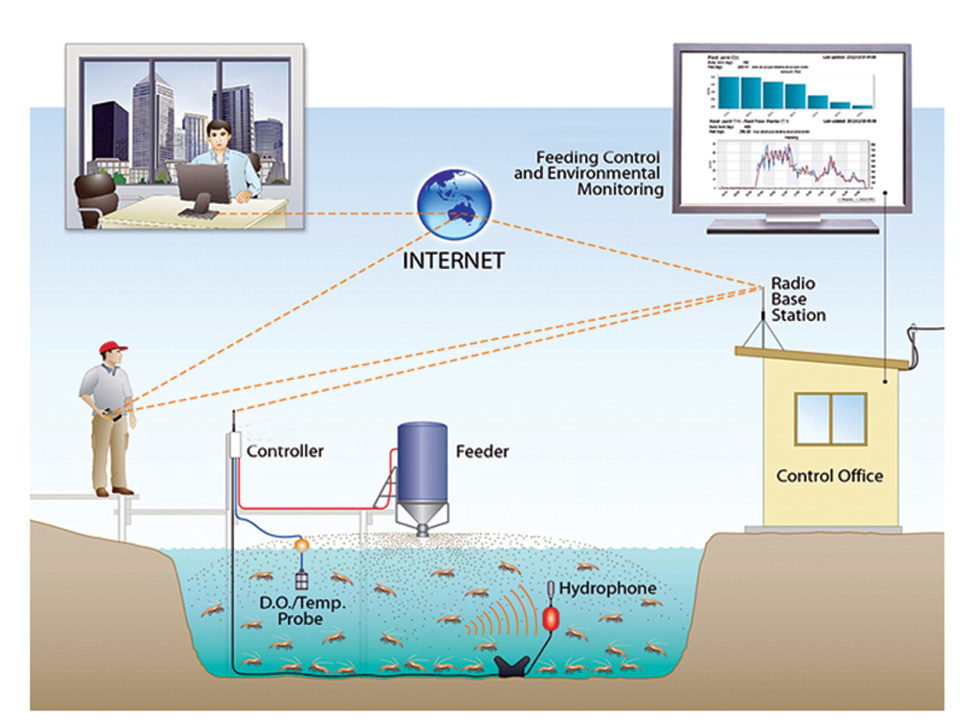

At the core of the system is a hydrophone, an underwater microphone that analyzes the many sounds that occur in the pond. These sounds are filtered by software that is capable of differentiating and recognizing specific noises made by the shrimp when they eat. A strong relationship between shrimp-feeding sounds and feed intake has been confirmed with feed trays, acoustic cameras and underwater cameras.

Once the shrimp-feeding intensity is known, the control algorithms in the feeding control decide when and how much feed is required and ensures it is all eaten. The latest sonic algorithms are self-learning, so the systems can be used for a variety of farm types and species.

In ponds, hydrophones are installed below the water surface in the distribution areas covered by the autofeeders, and the system controls feeding. The systems also monitor key environmental parameters and deliver alarms, as well.

System configuration is based on the number and size of the shrimp and the species grown. One hydrophone can monitor multiple autofeeders, and one control unit can monitor two hydrophones for two ponds. All data is communicated wirelessly to a computer in the farm office. The shrimp feeding activity and consumption rates are recorded, and the control software e-mails a daily feeding summary to the person in charge of the ponds. Additional information can be accessed remotely over the Internet.

Feeding studies

So far, detailed feeding studies have been carried out with Penaeus monodon, Litopenaeus vannamei and L. stylirostris shrimp weighing from 1 to 43 g. Additional studies with Marsupenaeus japonicus and Fenneropenaeus indicus are in progress.

In terms of pond size and stocking densities, positive tests have been run in 0.3- to 7.5-ha ponds. Stocking densities have varied 10-350 postlarvae/m2 so far.

Shrimp feeding behavior

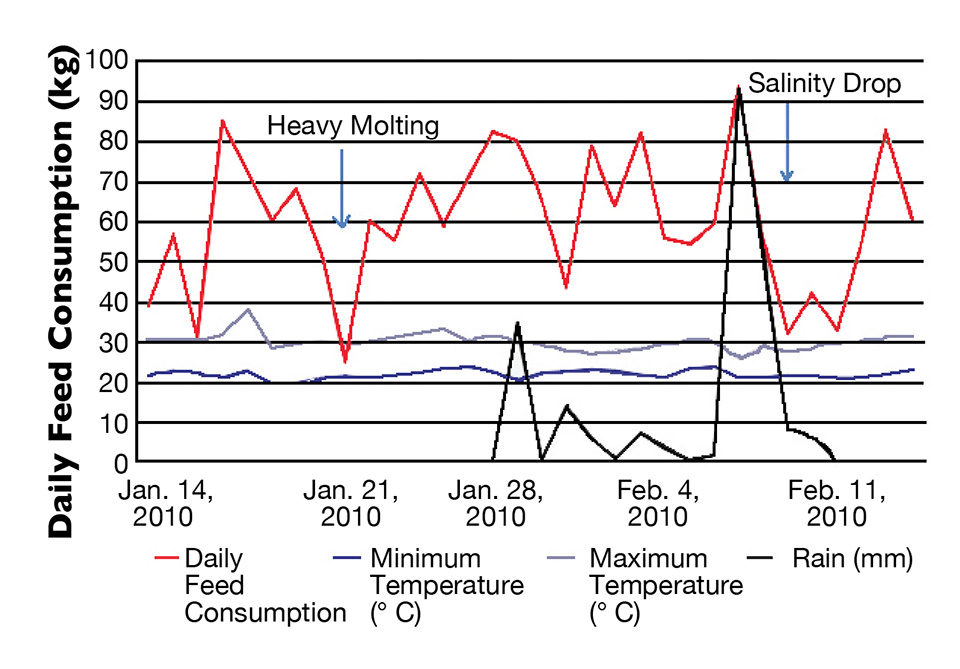

The usual feed rate reduction observed during the general molting cycle of the shrimp population is shown in Figure 1. A sudden drop of salinity in the ponds induced by heavy rains was also linked to a strong reduction of feed intake by shrimp in the following 12 to 36 hours.

Over a six-month cycle with P. monodon, the preferred time for feeding changed. Shrimp ate mostly at night in the warm season, but fed more during the afternoon as water temperatures fell. Not surprisingly L. vannamei were also seen to display preferential feeding patterns that related to such parameters as water temperatures and monsoonal activity in Asia.

At a spatial level, research has shown strong relationships among where shrimp eat in the pond and the prevailing winds, pond depths and oxygen levels. Data also indicated shrimp dispersed quickly away from the automatic feeding zones in large ponds after feeding based on the lack of detritus build-up under the feeders and cast net samples taken around the pond during and after feeding.

In the end, many factors influence when, where and how much shrimp eat. Even the most skilled farmer using feed trays and auto feeders cannot hope to deliver the optimal ration instantly all day without a closed-loop control system managing feeding.

Results at private farms

Trials have been undertaken on well-managed private farms in Australia with P. monodon from 2010, in Thailand with L. vannamei from 2011 and in New Caledonia with L. stylirostris from 2012. The trial objectives were to determine the natural feeding patterns of these species over 18- to 24-hour cycles, investigate the impacts of changes in environmental conditions on feed intake and assess the economic benefits from better growth, total harvested biomass and FCR reduction.

Productivity gains reflecting growth increases and FCR reductions averaged 25 to 30 percent across all species. A summary of the commercial trial results is shown in Table 1.

Bador, Average productivity gains, Table 1

| Species | Growth | Feed-Conversion Ratio | Feeding Method |

|---|

Species | Growth | Feed-Conversion Ratio | Feeding Method |

|---|---|---|---|

| L. vannamei | 12.1% | 12.3% | Auto feeder and hand feeding 4 times daily |

| P. monodon | 15.2% | 13.0% | Truck feeder 4 time daily |

| L. stylirostris* | 30.6% | -0.2% | Tray feeding 2 times daily |

Another significant benefit for automatic feeding control is improved pond bottom quality, especially in large ponds. Feed is no longer spread all over the bottom all cycle long. Instead, it is available only below the autofeeders and is consumed immediately when distributed, so that no excessive accumulation of feed is observed.

Perspectives

At today’s shrimp prices, the value of faster growth is very high. The return on investment for acoustic feeding control has been 3.5 times/2 crops in Thailand with white shrimp and 2 times/crop in Australia with black tigers. The labor savings and FCR gains reduce farm gate costs by more than 10 percent, which will be especially important when prices return to historical levels.

(Editor’s Note: This article was originally published in the November/December 2013 print edition of the Global Aquaculture Advocate.)

Authors

-

Regis Bador

Managing Director

Innov’Aquaculture

B. P. 15349

98804 Noumea, New Caledonia -

Peter Blyth

Director

Innov’Aquaculture

B. P. 15349

98804 Noumea, New Caledonia

-

Ross Dodd

Managing Director

AQ1 Systems Pty. Ltd.

Hobart, Australia

Tagged With

Related Posts

Aquafeeds

Automated feeding systems in pond production of Pacific white shrimp

Results of this study show that automated feeding systems are significantly more efficient than hand feeding in shrimp production ponds and that increases in feed input, application of adaptive technology and training of people to maintain the feeding system must all be considered.

Health & Welfare

Reporting of fish escapes, causes crucial step in developing better controls

Escapes of fish from farm facilities can lead to interbreeding and competition for mating opportunities with wild fish. Escapees may also transmit diseases and parasites, as well as compete for feed and space.

Innovation & Investment

Automatic submersible fish cage systems counter weather, surface problems

The development of submersible fish cage technologies may be necessary to avoid the operational challenges of surface-based aquaculture, which can include extreme temperature and weather conditions, jellyfish infestation, oil spills and many types of biofouling.

Health & Welfare

Egg saprolegniasis in a commercial sunshine bass hatchery

Fungal growth on the eggs caused by the water mold Saprolegnia spp. is an obstacle to the larval production of sunshine bass. This study confirmed that copper sulfate can be an economical and valuable resource in hatchery management for the control of saprolegniasis on sunshine bass eggs in McDonald jars.