A fluidized bed exposes sand particles to surrounding water

Fluidized sand beds (FSBs) have played an important role in the evolution of recirculation aquaculture systems (RAS), but technical problems have limited their application. Recent advances in FSB design have improved hydraulic efficiency, reliability, installation costs and maintenance.

How FSBs work

Conventional FSBs have been used most often for biological filtration in RAS to treat the culture water used to raise aquatic organisms. The fundamental concept is to expose the culture water to a very large surface area in a small volumetric space. One cubic meter of sand can have up to 25,000 square meters of available surface area (depending on the sand size). That surface area is habitat for specialized bacteria that oxidize toxic ammonia, excreted by the biomass in the culture tank, and convert it into nontoxic substances. The amount of ammonia that can be oxidized is proportional to the amount of surface area available for bacteria to populate.

FSBs utilize this surface area by “fluidizing” the sand. Water is injected at the bottom of a sand bed. The water flows against gravity, through the sand bed, lifting the sand as it travels. The packed or “static” bed becomes a viscous and fluid substance, with a clearly defined volume within the flowing water column it occupies. The volume of the fluidized bed is greater than that of the static bed. The reaction is similar to the reaction resulting from adding heat to a cold, dense gas. As it becomes warmer, the individual molecules become excited and start to vibrate and bounce around, requiring more volume per molecule.

As this happens, the overall volume of the gas begins to expand and the gas becomes less dense. The sand particles in a fluidized bed are analagous to excited molecules. Because the volume of the fluidized bed is larger, the exposed surface area of the sand is greater. Static sand is packed together with much of the surface area being covered and not exposed to water. A fluidized bed exposes the entire surface of every sand particle to the surrounding water at all times.

Disadvantages of conventional FSBs

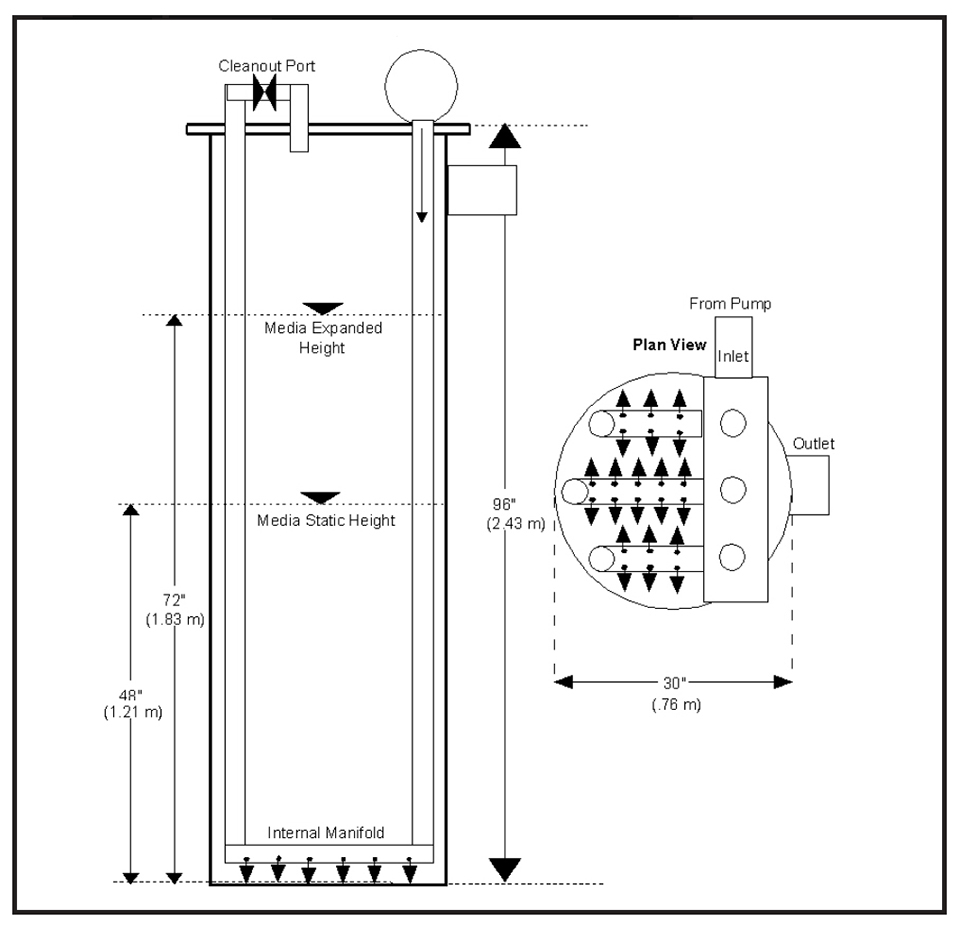

No matter how simple the concept, its application can often be complicated and frustrating. Conventional FSBs use a complex internal manifold with extensive plumbing to feed the manifold with water and provide a cleanout port (Fig. 1). The manifold lies in the sand bed at the bottom of the FSB chamber. There are several disadvantages to this internal manifolding. There is a large pressure loss due to piping and orifice outlets. Water velocities through the orifices are high and can be extremely abrasive and manifolds can easily become clogged with sand on shut down. The abrasive characteristics of water at high velocities and the presence of sand have been attributed to the catastrophic destruction of FSB chambers and the concrete floors they are built on.

Improved FSB design

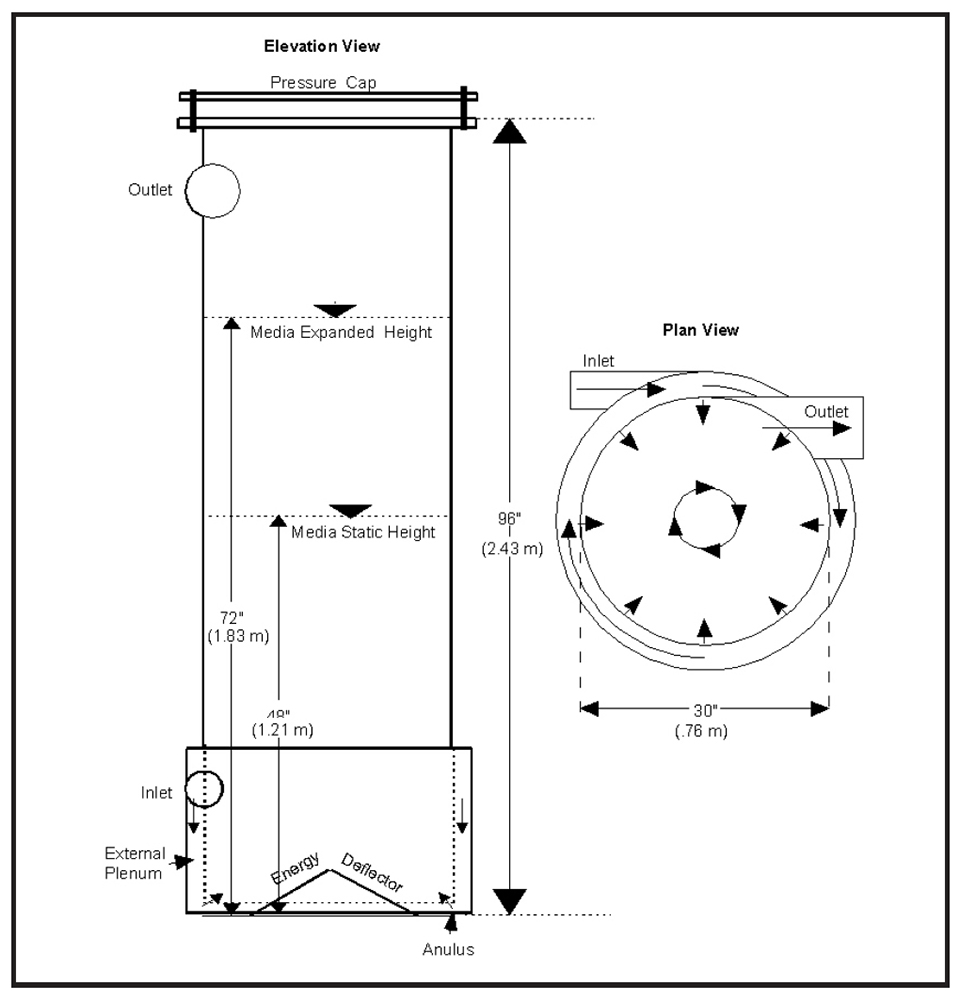

The new design concept replaces internal manifolding with an external plenum chamber around the base of the FSB chamber (Fig. 2). This results in improvements in hydraulic efficiency, and a significant decrease in installation labor and costs. Water is introduced tangentially to the circumference of the cylinder, 0.25 to 0.75 meters from the bottom of the cylinder. The water fills the plenum chamber and is forced out through an annulus (short opening) that runs 360 degrees around the base of the sand bed. An energy deflector in the bottom center of the sand bed eliminates the possibility of static spots within the sand column.

The water velocity through the annulus is reduced by approximately 90 percent from the water velocity through conventional orifices. This contributes to hydraulic efficiency, greatly reduced operating cost, and is thought to offer a more hospitable environment to bacteria living on the sand, increasing the nitrification rate per unit volume of reactor space. The circular velocity created by the tangential inlet is transmitted through the entire chamber and can be visually verified at the top of the column where the water exits.

A device utilizing this concept may be pressurized and/or run from a header tank. The design is highly scalable, currently from 6 inches (0.15 meters) to 11 feet (3.35 meters) in diameter. Its scalability is one of its major advantages. An 11-foot diameter device is capable of oxidizing the total ammonia nitrogen produced by a biomass on the magnitude of 50,000 kg under intensive commercial conditions. Operating pressure is about one-third that of conventional systems. Little to no maintenance is required once it is in operation. It may be run with a variety of sand sizes and is adaptable to most RAS applications.

FSBs are unique in providing a large surface area for biofiltration in a small volumetric space. They also avoid issues of channelization and anaerobic zones associated with other biofilter designs. The external water delivery manifold described here further improves hydraulic efficiency and performance. This will increase the application of FSBs for aquaculture.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Edward D. Aneshansley

Marine Biotech, Inc.

54 West Dane St., Suite A

Beverly, Maine 01915 USA[109,111,99,46,104,99,101,116,111,105,98,101,110,105,114,97,109,46,119,119,119]

Tagged With

Related Posts

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Health & Welfare

Biofilter inoculation in recirculating aquaculture systems

Biological filters are essential parts of recirculating aquaculture systems that transform toxic fish compounds such as ammonium and nitrite into less-harmful nitrate. The authors tested the convenience and efficiency of three methods for the initial inoculation of aerobic biofilters.

Health & Welfare

Brunei project develops technology for large black tiger shrimp production, part 3

Specific pathogen-free offspring developed from founder populations of P. monodon collected from Brunei coastal waters were introduced into a biosecure breeding program, where they have been reared to the fifth generation using family-based selection for reproduction and growth.

Responsibility

Microbead filters: cost-effective, scalable filtration

Microbead filters are an effective filtration solution that can be scaled to large production systems at a lower cost of operation than fluidized-sand bed filters.