Practical applications

Aerated microbial reuse (AMR) systems use intense aeration and mixing to produce yields of 10 to 30 metric tons (MT) per hectare per cycle with little or no water exchange. These systems recycle nutrients in the form of organic detritus, which consists of aggregates of organic particles coated with a film of bacteria. The bacteria absorb nutrients from the particles and surrounding water, which purifies the water. The enriched particles serve as a nutritious source of food for detrital feeders such as shrimp and tilapia. The composition of the detrital material – often called “floc” – varies widely, but it is generally rich in protein and minerals. The presence of a rich microbial floc can substantially reduce the requirement for formulated feed.

Reducing feed protein

Trials with both tilapia and shrimp have demonstrated that feed protein levels can be reduced in these systems. In 1992 trials in Israel, Avnimelech and coworkers compared the performance of 32 and 20 percent protein diets for tilapia in highly intensive tanks with low water exchange. The low protein diet resulted in higher yields, larger final weight, lower mortality, improved FCR, and greater profitability than the higher protein diet.

In 1994, Hopkins and coworkers at the Waddell Mariculture Center in South Carolina, USA, compared performance of L. vannamei in aerated zero-water-exchange shrimp ponds with 20 percent or 40 percent protein. They found no difference in production (all treatments ranged from 6 to 8 MT per hectare).

In 2000, Velasco and coworkers at Texas A&M University conducted a series of trials with postlarval L. vannamei, using protein levels ranging from 5 to 33 percent and lipid levels ranging from 3 to 11 percent in static aerated tanks as well as in tanks receiving recirculated water from a common external filtration system. Only those diets with less than 15 percent protein produced significantly lower growth. The optimum protein level estimated through quadratic and broken-line regression was 20 to 25 percent.

Reducing fishmeal usage

The presence of microbial protein can also reduce the quantity of fishmeal required in shrimp feeds. In commercial trials in Belize, McIntosh reported yields of 14.5 MT per hectare per cycle with an FCR of 2.0 using diets with only 24 percent protein, and less than 10 percent fishmeal inclusion (see December 1999 Global Aquaculture Advocate, pages 40 to 47). In trials last year in outdoor microcosm tanks at the Oceanic Institute in Hawaii, USA, Tacon and coworkers reported no significant difference in performance of shrimp fed a fishmeal-based diet versus a diet in which 100 percent of fishmeal was replaced with meat and bone meal.

https://www.aquaculturealliance.org/advocate/advantages-of-aerated-microbial-reuse-systems-with-balanced-cn-part-1/

Dilution of feeds with carbohydrate

The first article in this series described the importance of maintaining the proper balance of carbon to nitrogen (C:N) for suitable bacterial utilization of waste. In order to achieve the appropriate C:N, conventional feeds can be diluted with carbohydrate. In 1999, Avnimelech and coworkers calculated the percentage of carbohydrate to add directly to a 30 percent protein tilapia feed to reduce C:N using the following assumptions:

- Content of 30 percent protein diet = 4.8 percent nitrogen.

- Ammonia N available for recycling after excretion = 50 percent.

- C:N ratio of microbial tissue = 4.

- Carbon content of carbohydrate = 50 percent.

- Efficiency of microbial protein synthesis = 40 percent.

- Carbohydrate to add to diet = 4.8 percent * 50 percent * 4 per (50 percent * 40 percent) = 48 percent.

The same formula can be used to adjust other feeds for AMR systems.

Establishing microbial floc

One of the challenges of AMR systems is to design a diet that serves both the target organism as well as the microbial community. For example, at the start of the production cycle, biomass and associated feed requirements are quite small and protein requirements are high. An appropriate feeding rate for such a small biomass would be inadequate to initiate a microbial floc. On the other hand, it would be prohibitively expensive to allocate a sufficient quantity of formulated feed to establish an early floc.

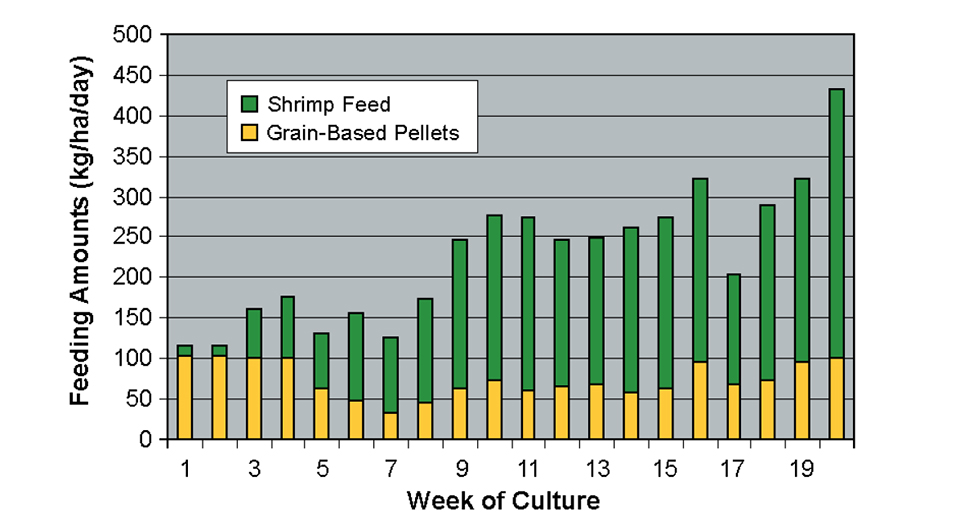

At the end of the cycle, the protein requirements are considerably less, due to the need for a high C:N to prevent accumulation of inorganic nitrogen. To avoid continually reformulating diets, McIntosh (2000 b) utilized initial applications of an inexpensive grain-based pellet with high C:N at the start of the cycle to initiate the floc. During the course of the cycle this regime was adjusted transitioned to a lesser application of grain-based feed and a greater application of formulated shrimp feed (Fig. 1). The disadvantage of this approach is that juvenile shrimp grow faster on a high protein feed.

Economic implications

Historically, the process of intensification of aquaculture systems has been based on increasing levels of water exchange. As intensity increased, the contribution of natural foods diminished, due to increasing water exchange and increasing predation associated with higher stocking densities. The diminishing contribution of natural foods required development of more nutritionally complete and more expensive formulated diets for intensive systems. Consequently, feed cost was an economic barrier to intensification.

The development of AMR systems, reverses this trend. In AMR systems, the contribution of natural foods increases with increasing density, which spares the cost of formulated feeds. In a 1994 study, Avnimelech and coworkers estimated that tilapia feed cost was reduced by 30 percent in AMR systems. Given the fact that feed is the largest operating cost in most animal production efforts, AMR systems are expected to reduce the economic barriers to intensification.

Future research

AMR systems have demonstrated remarkable potential, but many questions remain. One yardstick of success is nitrogen assimilation efficiency, which is still only about 50 percent in commercial systems.

In-depth modeling is needed to improve researchers’ understanding of the contribution of various components of the pond community to transfer of energy, nitrogen and phosphorus within the system.

To optimize pond hydraulics and efficiency, the optimal levels of organic loading and mixing must be defined. Inadequate loading limits formation of microbial flocs, but proper loading with inadequate mixing leads to sedimentation and anaerobiosis. Excessive organic loading requires high levels of turbulence, which are likely to stress animals.

Community succession

To reduce the difficulty of initiating a microbial floc at the beginning of a cycle, it seems sensible to carry over flocs from one cycle to the next – much like activated sludge sewage treatment systems. This would facilitate head starting new pond cycles with mature and efficient stages of community succession.

Management as rumen

Several researchers have alluded to the possibility of managing AMR systems like the rumen of a cow. The concept is to combine low value carbohydrates with inorganic nitrogen to encourage in situ production of bacterial protein. McIntosh tested this concept in a pond trial in Belize, where only pelleted wheat grains, trace minerals, urea, and diammonium phosphate were utilized. Postlarval LP. vannamei stocked at 120 per square meter grew to 7 to 8 grams on only these inputs. Growth rates averaged about 0.5 grams per week. Production reached the equivalent of 8 MT per hectare. This demonstrates the presence of substantial nutritional value from bacterially-enriched detritus.

Probiotics

It seems clear that some components of the microbial community are quite beneficial in terms of growth-promoting qualities and nutritional value. An obvious opportunity would be to specifically seed these microbes to improve pond performance. Conceivably, bacteria could be selected with characteristics such as balanced amino acid profile, proper agglutination agglutinization, etc. An easy way to start this process is simply to reuse water from high performing ponds. McIntosh has started a biological library of various stocks that appear in ponds to allow future selection.

Conclusion

Aerated microbial reuse systems offer practical opportunities for improved efficiency and cost reduction through reduction of feed protein levels and fishmeal inclusion. Formulas are provided for calculation of carbohydrate dilution to achieve the proper balance of carbon to nitrogen for bacterial utilization of waste. The recycling of nutrients in AMR systems facilitates important savings in feed cost, which reduce former barriers to intensification.

(Editor’s Note: This article was originally published in the October 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

George Chamberlain, Ph.D.

Global Aquaculture Alliance

St. Louis, Missouri, USA -

Yoram Avnimelech, Ph.D.

Faculty of Agricultural Engineering Technion

Israel Institute of Technology

Haifa, Israel -

Robins P. McIntosh

Belize Aquaculture, Ltd.

Belize City, Belize -

Mario Velasco, Ph.D.

Bioexportables S.A.

Guayaquil, Ecuador

Tagged With

Related Posts

Aquafeeds

Advantages of aerated microbial reuse systems with balanced C:N, part 1

An alternative waste treatment is intense microbial processing of wastes to facilitate high yields with little or no water exchange.

Aquafeeds

Advantages of aerated microbial reuse systems with balanced C:N, part 2

Aerated microbial reuse systems utilize intense aeration and mixing to produce yields of 10 to 30 metric tons per hectare per cycle with little or no water exchange.

Responsibility

Simple settling chambers aid solids management in biofloc system

A study examined the effects of removing suspended solids using side-stream settling chambers in a superintensive biofloc shrimp system. The chambers reduced nitrate-nitrogen and phosphate concentrations and improved shrimp growth rate and biomass.

Aquafeeds

Testing shrimp growth in different biofloc systems

A study conducted with juvenile shrimp (Litopenaeus vannamei) reared in experimental biofloc systems used four treatments. Results indicate that differences in management and carbohydrate source can lead to substantial disparity in system function and production.