Aquaculture consumes 60 to 80 percent of fishmeal and 80 percent of fish oil produced

According to the Food and Agriculture Organization of the United Nations, fisheries and aquaculture are vital to global food security and poverty alleviation. Research to increase the sustainability of aquafeeds is essential for aquaculture to fulfill its potential in providing high-quality protein for the global population of the coming decades.

A major challenge facing the continued growth of aquaculture is that most fish feed needs high levels of protein and energy. For carnivorous or omnivorous fish, these are traditionally provided mainly in fishmeal and fish oil, which also contribute to the health-promoting aspects of fish in the human diet – for example, with omega-3 fatty acids. The challenge lies in the need to increase feed production without increasing the demand for marine raw material resources and while maintaining health benefits.

Aquaculture today takes 60 to 80 percent of the fishmeal and 80 percent of the fish oil produced, mainly from the industrial pelagic fisheries and trimmings produced during processing for human consumption. The industry is, therefore, heavily dependent on marine resources, but production from these resources cannot be increased sustainably. At best, sustainably managed fisheries will continue to yield the current annual harvest of 5 million metric tons (MT) of fishmeal and 1 million MT of fish oil. Therefore, to meet the growing demand for fish, aquaculture must identify alternatives.

Research progress

Researchers around the world are continually looking for alternatives that will provide low feed-conversion ratios, maintain high fish welfare and produce fish that are good to eat, both in terms of eating experience and nutrition.

Dr. Wolfgang Koppe, manager of the Nutrition Department at the Skretting Aquaculture Research Centre (ARC) in Stavanger, Norway, reported that the department has determined the nutritional value of more than 400 raw materials. In 2010, ARC researchers finalized what Skretting has dubbed MicroBalance technology, which has greatly reduced dependence on fishmeal.

Initially this was based on ensuring a correct balance of newly identified essential micronutrients in feeds for Atlantic salmon. Normally these are provided in fishmeal, but the researchers identified alternative sources. Identifying alternatives to fishmeal provides flexibility to adapt the raw material combinations in response to prices, lessening the impacts of price volatility on farmers.

Fishmeal levels in the average Atlantic salmon grow-out diet were previously around 25 percent. The ARC advances enabled Skretting to produce commercially successful feeds with just 15 percent fishmeal. Continuing research led to grow-out feeds with fishmeal levels of just 5 to 10 percent.

More species

Researchers are now applying the technology to other established aquaculture species, including sea bass, sea bream, rainbow trout, turbot and yellowtail. Skretting ARC is currently establishing a satellite research center in China to help address diets for marine species raised in Asia, which now typically receive feed with 20 to 30 percent fishmeal.

In 2011, the ARC recruited shrimp nutrition specialists and began research activities to transfer the MicroBalance technology to shrimp feed. The new research facility in China will play a key role in this project.

Feeds for crustaceans have traditionally used relatively high fishmeal levels of 20 to 30 percent. These inclusion levels vary with the shrimp species and the type of production targeted – semi-intensive or intensive.

Dr. Lenaig Richard, a researcher at Skretting ARC, said that considering the knowledge gained by the center in fish species, there is great potential for reducing the overall reliance on fishmeal in shrimp feeds, as well. However, Koppe said that identifying alternative sources of the essential macro- and micronutrients provided by fishmeal is only part of the story. The second part lies in discovering how best to manufacture the feed when using these new raw materials.

Manufacturing challenges

Raw materials such as concentrated proteins from soybeans, wheat, peas or sunflowers are used in low-fishmeal feeds to provide the macronutrients normally delivered by fishmeal. They are supplemented with further ingredients to provide the essential micronutrients still required for complete nutrition.

Replacement of fishmeal is not straightforward in production terms. It is necessary to acquire knowledge about the functionality of plant proteins before such materials can be fully used in a commercial context.

To begin, the substitution of fishmeal by vegetable raw materials changes the physical properties of the raw material mix and therefore the way it behaves in the extrusion process involved in producing feed pellets. Skretting ARC has a pilot-scale feed plant in which researchers have been developing production methods that enable the operators to control the production process and the resulting physical properties of the feed pellets.

Physical characteristics

In addition to providing the nutrients required by a particular species, the feed pellets must match a series of physical specifications. These vary among species and among growth stages within species.

Feed pellets should not crumble and must be sufficiently robust to withstand handling, for example, in transfer from one silo to another or storage in bags. They must be consistent in size, shape and density, and the density must be controlled precisely to give the required floating or sinking characteristics. Also, the pellets need to be stable during storage, especially at higher temperatures, to avoid loss of oils and other nutrients.

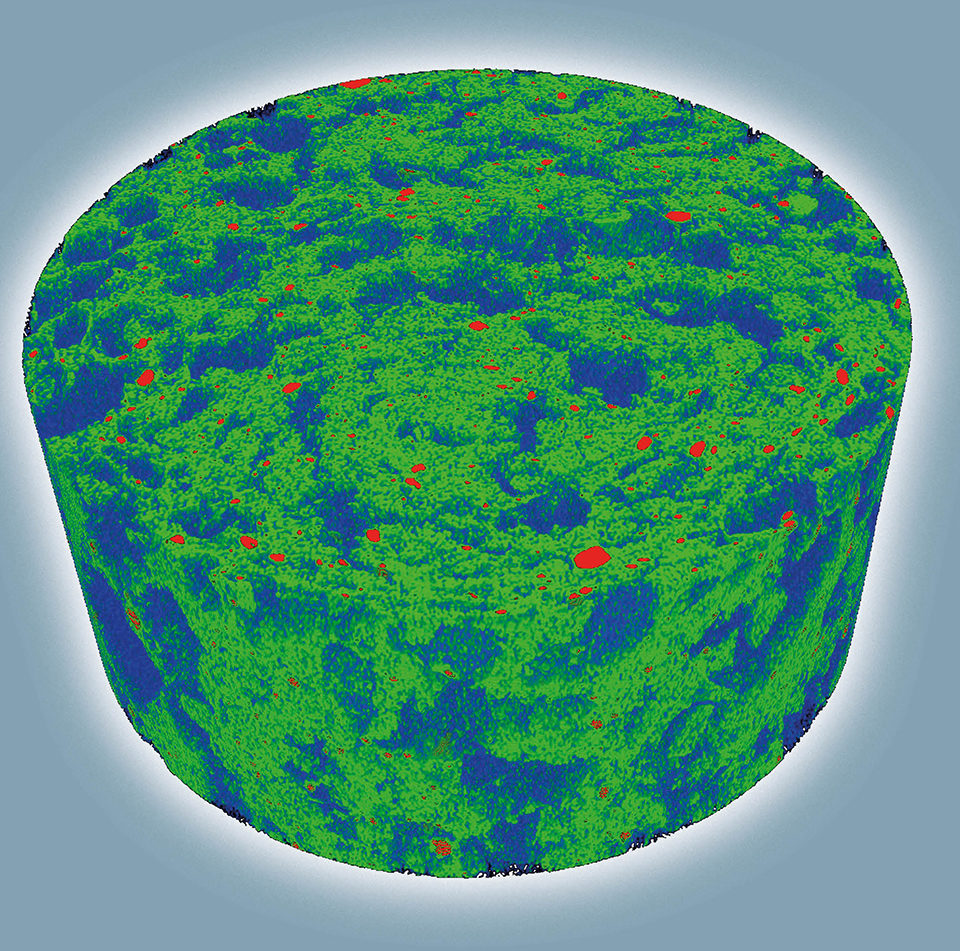

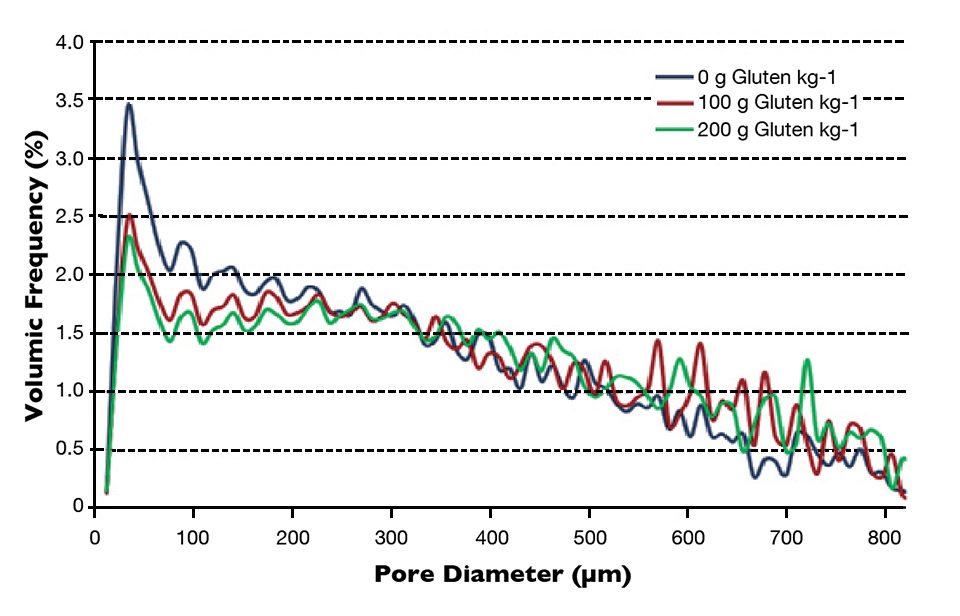

Vukasin Draganovic, a doctorate candidate at Skretting ARC, is exploring how suitable ingredients behave in terms of their processing, their interaction with other ingredients and the end physical qualities of the feed in a project being conducted with the Food Process Engineering Group at Wageningen University. Fig. 1 is an example of one test of feed pellets.

With funding through the Industrial Ph.D. program facilitated by the Research Council of Norway, his work is also focusing on the impacts of the transition toward vegetable proteins on the energy consumption of feed plants and identifying options for more energy-efficient processes with lower carbon footprints. Draganovic reported that energy usage during feed processing can be greatly reduced by modifying the plant proteins to match the technological properties of fish protein.

Equivalent projects are addressing the need to reduce dependence on fish oil.

(Editor’s Note: This article was originally published in the May/June 2013 print edition of the Global Aquaculture Advocate.)

Author

-

Dr. Alex Obach

Managing Director

Skretting ARC

P.O. Box 48 – 4001

Stavanger, Norway

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.