Alltech, Benchmark Holdings addressing farmed salmon’s primary pest from different angles

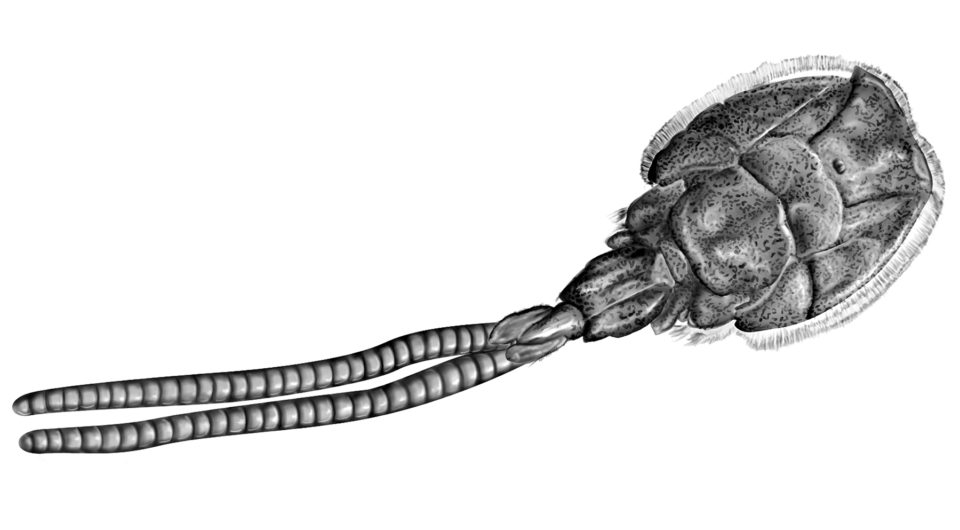

Sea lice may be tiny creatures, the size of a green pea, but they cause enormous problems for farmed salmon. Latching onto the fish’s skin, they cause lesions, diseases and mortalities, costing the global aquaculture industry some $1 billion a year.

Lice-fighting measures helped drive wholesale Atlantic salmon prices in late 2017 50 percent higher than at the close of 2016. An estimated $1 per kilogram of what consumers spend on farmed salmon goes to lice control, according to Pearse Lyons, president of Alltech in Lexington, Ky., one of the animal health companies working on solutions.

Despite an arsenal of chemical and non-chemical treatments – from hydrogen peroxide to SLICE, medicines and the emerging use of cleaner fish like wrasse and lumpsuckers – sea lice remain a tremendous problem for salmon farmers.

So when Lyons made a bold statement last October in his hometown of Dublin, Ireland, before an audience of aquaculture professionals at GOAL 2017, people took notice. Alltech generates $2.1 billion in annual sales.

“I believe we will conquer and eliminate sea lice in six months,” Lyons said.

It’s not necessary the claim made about solving the sea lice problem that was bold. Ian Bricknell, professor of aquaculture biology at the University of Maine, said it was the timeline that was rather optimistic.

“I was once told by a colleague that they had a product that would eliminate sea lice as a problem within six months,” said Bricknell. “That was in 1991.”

Dr. Karl Dawson, chief scientific officer at Alltech, said in mid-February that there is no easy fix and conquering the problem within the next three months was probably unrealistic.

Still, Alltech is confident it has a game-changer on its hands.

“If we are successful with our initial approaches in the next couple months, we can look forward to changing the impact of lice in salmon over the next year,” said Dawson. “We are most likely talking about improving the situation within six months of the time the product reaches the market.”

Two new answers marching to market

At one other company along with Alltech, Benchmark Holdings in London, has been hard at work on the next generation of solutions and believes it has new products in the works that can help salmon farmers win their war against the pests.

Alltech is testing a substance that, when injected into young Atlantic salmon, turns some genes on and some off, in effect programming the fish’s immune system to better defend itself against sea lice.

“I get pretty excited when I think about it,” said Dawson. There is potential to impact the sea lice problem and other parasitic diseases as well, in salmon and other species, he added.

“As of today,” said Dawson in mid-February, “we are examining the first results from challenge studies and continue to feel we have an approach that will help control the sea lice problems in salmon.”

If we can influence the innate immunity in chickens, can we do the same thing in fish?

Alltech is using genetic technology to predict how those fish will respond to sea lice. The company needs further testing under proper seasonal conditions to see if reality bears out the promise of initial testing, said Dawson.

“Even if this one doesn’t come out exactly the way we think it’s going to, we’re learning and what we can put together on this is really going to be exciting,” said Dawson.

Yet, both companies caution that when it comes to sea lice, there is no silver bullet approach.

Benchmark’s medicinal bath

Benchmark, an aquaculture health, nutrition and genetics company with operations in 27 countries, has a sea lice treatment in late-stage development, stated Dr. Matt Haslam, veterinary surgeon and head of CleanTreat®, via email.

The new product, Ectosan®, is more traditional, in that it’s a medicinal bath treatment, administered in a similar fashion to hydrogen peroxide. But Ectosan® is used in tandem with the company’s CleanTreat® purification system, which is designed to work with wellboats, tankers, platforms or on land. One unit treats 200 cubic meters of water per hour, according to Benchmark’s promotional video, and the system can be tailored to any volume of water and biomass of salmon by adding units.

Benchmark’s website announced the success of Ectosan® during initial commercial-scale field trials.

The treatment showed 100 percent efficacy against sea lice, a result so promising that Benchmark now estimates 45 million British pounds in peak projected sales. The treatment is making its way through additional field trials and the regulatory process in Norway.

“[The] CleanTreat® system’s proven ability to deliver the treatment without ocean water contamination underpins its potential for commercial deployment across wider applications,” according to Benchmark’s website.

The fish are bathed and once they are returned to the sea the treatment water is pumped through the CleanTreat® unit. Onboard chemists test the water using high performance liquid chromatography. The chemists can measure medicine levels to non-detectable limits in as little as seven minutes. Once the medicines are at non-detectable levels, the chemists approve discharge of the treated treatment water to the sea. Pen-by-pen, the farm is treated for sea lice and there is no impact from delousing medicine, according to Benchmark.

“This is a major breakthrough for Benchmark and the salmon industry,” Benchmark CEO Malcolm Pye stated on the website. “The combination of our next generation sea lice treatment, together with CleanTreat® represents a transformational change in the battle against one of the industry’s greatest challenges, and a big step towards a future where no medicinal residues are discharged directly into the oceans.”

Benchmark declined to provide additional information, citing requirements of the regulatory process.

Bricknell noted that all medicinal treatments including SLICE and Salmosan, initially showed 100 percent efficacy when they were first introduced. But over time the lice became resistant and those treatments lost their effectiveness.

However, the combination of Benchmark’s new medicinal and the CleanTreat® system is promising, said Bricknell.

While treatments kill most lice, some survive to pass along the genetics that allowed them to do so onto the next generation of animals. In this way, the animals build resistance to medicines over time.

So Benchmark’s ability to separate those animals as it treats the water is definitely a plus, said Bricknell.

“Because they’re not releasing any of the treated lice into the environment, they won’t have the problem of releasing animals that had a sub-optimal treatment,” said Bricknell.

In this scenario, CleanTreat would prevent those pest animals from release into the environment as it treats the water, which would at least slow their ability to develop resistance to a new treatment. Bricknell also advises farmers to rotate the drugs used in treatment to reduce or prevent those resistant genes from getting a hold in the sea lice population.

Alltech’s journey to breakthrough

In the last year or so, a few developments came together that led Alltech to a breakthrough – and likely led to its president’s optimism.

Alltech has been working with a mannan-rich cell wall fraction, a carbohydrate belonging to a group called glucans it derives using a proprietary process from the outer cell surface of a specific strain of yeast, Saccharomyces cerevisiae 1062.

That material is the basis for Bio-Mos®, a feed additive used to improve the function of the digestive system in animals, also known as gut health. Actigen® is a newer Alltech product that is a more purified version of Bio-Mos®.

“The interest in using this material originally came from studies in chickens that indicated that early life exposure to the mannan-rich fraction improved the innate immunity of chickens,” said Dawson, in a company blog post from last year.

Alltech researchers have been, in essence, deconstructing that new cell wall material to understand how it works and affects animal health.

They learned that when that material is put into the egg of a chicken, it enhances the chicken’s immune response throughout its lifetime.

“That’s where the idea got started here,” said Dawson. “If we can do that – influence the innate immunity in chickens – can we do the same thing in fish?”

Salmon, of course, have different biology than chickens.

A new, injectable material

While Bio-Mos is a feed additive, the company is testing an injection approach. It has found ways to make the mannan sugar substance more concentrated.

It has also tapped the ingredients in Aquate – a feed additive designed to promote good bacteria, build defenses and promote gut health.

For one, Aquate leads fish to secrete more mucous which helps protect it from bacteria and sea lice.

“We’ve always observed that that material does have the ability to change the surface of fish,” said Dawson. “The skin of the fish changes.”

Using knowledge and substances found in both Aquate and Bio-Mos, Alltech developed a new, injectable material.

“We can include this material as part of the vaccination and bring about some of these changes,” said Dawson.

In late 2016, Alltech started discussing using this approach for farmed salmon.

In its testing, Alltech is studying gene expression of salmon to understand effects of the injection substance on the fish’s immune system. That process helps the company predict how the fish will respond throughout their lives to sea lice.

The company developed that process by working with the GeneChip™ – a trade name for a DNA microchip technology that measures gene expression.

GeneChip™ provides information for 25,000 to 30,000 genes at once, noted Dawson. Alltech developed a proprietary process to annotate it.

“That was a barrier we had to overcome, when we started working with this concept in fish,” said Dawson. “So when we think about revolution here, we’re kind of changing the science as we go, too,” he said, referring to Alltech’s work on annotating the information.

Researchers found that out of those 25,000 genes, there are seven or eight marker genes that indicate how the fish will respond. In the initial test, scientists injected the substance into salmon, then waited six weeks to see if the some of the salmon’s genes were turned on or off by the injection in a way that makes the fish better suited to fight sea lice.

One of those handful of genes controls how much mucin the fish makes – in other words, how slimy it will be, which helps protect it against sea lice. Alltech’s goal is to turn that one on, along with the gene for tissue repair. But it is trying to “down-regulate” other genes.

Some gene expression is turned on and others are turned off, in a combination that makes the fish better able to fight sea lice.

The process does not change the fish’s DNA, noted Dawson.

“We don’t manipulate the genetics of the fish,” he said. “We just take the genes of the fish and control their expression.”

Norway testing the concept

NOFIMA, the Norwegian Institute of Food, Fisheries and Aquaculture, an industry salmon research unit, is growing about 350 fish in a net-pen setup that replicates a commercial farm. Those fish were injected last fall, and samples were recently taken and evaluated using Gene Chip technology.

“We know we are in fact inducing the changes we expected from our chicken model,” said Dawson, and that confirmed the concept is working.

The ultimate test, of course, said Dawson, is how the fish actually respond to actual sea lice. That’s happening early this year, depending on weather conditions.

Next will be the regulatory process to bring the product to market. Dawson said that will be the U.S. Food and Drug Administration, however he is unclear which area of the FDA.

The company is looking at applications for human health. Clinical studies are underway to evaluate the material found in Bio Mos and its effects upon the human immune system. Alltech employees carry Bio Mos tablets with them when they travel internationally to prevent gastrointestinal problems.

The idea of functional feeds or nutraceuticals that improve gut health, defend against bacteria, improve good bacteria and signal the immune system has been around animal and human health nutrition.

“Nobody has really got to grips for optimizing it for sea lice,” said Bricknell.

The drawback, however, is immuno-tolerance. Too much consistent use of an immuno-stimulant leads to the body becoming tolerant to the compound.

But since no one has taken such an approach to help farmed salmon fight sea lice, Bricknell, said there is significant potential. Whether or not it transforms an industry in a few months remains to be seen.

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Lisa Duchene

Lisa Duchene has reported on the marine environment for two decades. She is a business-environment writer in central Pennsylvania. Lisaduchene.com.

Related Posts

Health & Welfare

Chem-free fixes emerging in sea lice saga

Salmon farmers, using emerging technologies, are exploring new methods of sea lice mitigation in an effort to overcome one of the industry’s most persistent problems. New chemical-free innovations show an industry eager to adapt and adopt environmentally safe practices.

Health & Welfare

In sea lice fight, salmon farmers phasing out hydrogen peroxide

An over-reliance on medical and chemical controls, along with warming waters, led to a surge in sea lice. With such treatments waning in effectiveness, operators turn to other, safer measures.

Innovation & Investment

Thinking outside the cage: Avant-garde aquaculture in Norway

Salmon farming in Norway is poised for an innovation boom. The biggest players are putting cutting technology in the water to solve some of the industry’s most persistent problems, such as sea lice, fish escape and waste management.

Intelligence

Omega-6s and the threat to seafood’s healthy halo

Research shows farmed fish fed diets heavy on vegetable oils have higher amounts of omega-6s and lower amounts of omega-3s, compared to fish fed diets heavy on fish oil. We take a deep dive into the relationship between the two fatty acids.