Ethoxyquin provides effective protection against oxidation

High-quality feed is essential for the optimal performance of cultured animals. Many processes can negatively impact feed quality, but oxidation can be a factor through the entire feed production operation. Managing quality from the production of feed ingredients through feed manufacture, grow-out, and processing is essential in consistent, high-quality food production.

Effects of oxidation

Oxidation is defined as the act or process of oxidizing or being oxidized. It entails the transfer of electrons from one molecule to another. In the process, highly unstable and reactive free radicals are formed, which lead to the presence of peroxides and other equally reactive secondary and tertiary oxidative byproducts. Oxidation is quite rapid in feeds and feed ingredients when not interrupted.

The nutrients most susceptible to oxidation are fats, fat-soluble vitamins and xanthophyll-type pigments. Protein quality can also be negatively impacted due to heat generated during uncontrolled oxidation. Several factors affect the rate and intensity of oxidation reactions. Among them are the specific type of raw material, amount of surface area, exposure to air, and the presence of oxidative catalysts, specifically iron and copper.

Fishmeal is particularly prone to oxidation due to its high levels of unsaturated fatty acids and extensive surface area. Dramatic effects of oxidation have been seen in fishmeal, which can self-heat and combust. Other, more subtle effects include reduced metabolizable energy, compromised protein quality, and cell damage. These effects will be reflected in depressed feed performance, with reduced animal weight gain, poor feed conversion, increased disease susceptibility, and greater mortality.

Research across species has confirmed the deleterious effects of oxidized animal protein meals. As an example, in broilers chickens, both weight gain and feed conversion were negatively impacted. In high-protein shrimp feeds with greater proportions of fishmeal, controlling oxidation is of great importance due the extreme sensitivity of shrimp to peroxides and other oxidative byproducts.

Oxidation prevention

Oxidation is best prevented through the use of antioxidants. When added early in the feed-manufacturing process, antioxidants are oxidized before the fats and oils, and the resulting oxidized antioxidants are stable. It is important to remember that antioxidants stop the oxidation process, but cannot reverse it or eliminate previously generated oxidative byproducts.

Antioxidants stop oxidation by contributing free electrons to stabilize the reactive free radicals present in feed ingredients. The excess energy created by the free radicals on the antioxidant molecules is dissipated throughout the entire molecular structure, rendering them stable.

Common synthetic antioxidants include ethoxyquin, tertbutyl hydroquinone (TBHQ), butylated hydroxani-sole (BHA), and butylated hydroxytoluene (BHT). Natural antioxidants such as tocopherols can also be used, but they need to be added at multiple concentrations of the synthetics to have similar effectiveness.

Ingredient quality, antioxidant efficacy

A number of analytical methods are used to measure the quality of feed and feed ingredients. Common methods include measuring for protein, moisture, fat, fiber, and ash. Measures of amino acids, pepsin digestibility, and available lysine and methionine are also used to assist in formulating diets.

The chemical methods for measuring ingredient quality can be separated into general procedures and those used to measure oxidative stability. General methods include titer, moisture, insolubles, unsaponifiables, saponification number, free fatty acid, and fatty acid profile testing. Total volatile nitrogen and biogenic amines (histamine) are additional quality tests used specifically in fishmeal production.

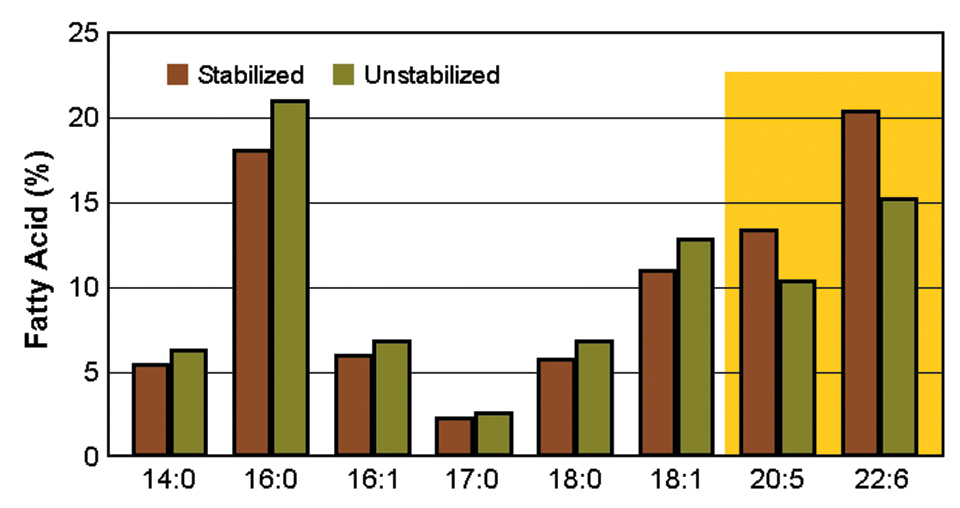

The fatty acid profiles of feed ingredients can be used to measure changes during the storage of fishmeal. In Fig. 1, oxidation decreased the omega-3 fatty acids in fish oil extracted from a meal. Ethoxyquin added as an antioxidant at 750 ppm as a positive control demonstrated that the negative effects of oxidation can be reduced through the use of an antioxidant.

Measurements of oxidative stability include peroxide value, active oxygen method, oil stability index (OSI), oxygen consumption, iodine number, and anisidine value. Each of these tests produces a different result, so it is necessary to understand the differences between the test methods.

Oxidation causes fats and oils in feed to absorb oxygen from the atmosphere. The oxygen consumption test measures this factor. Free radicals attack fatty acids, break down double bonds, and produce the primary products of oxidation called peroxides. The iodine number and peroxide value test methods measure these oxidative changes.

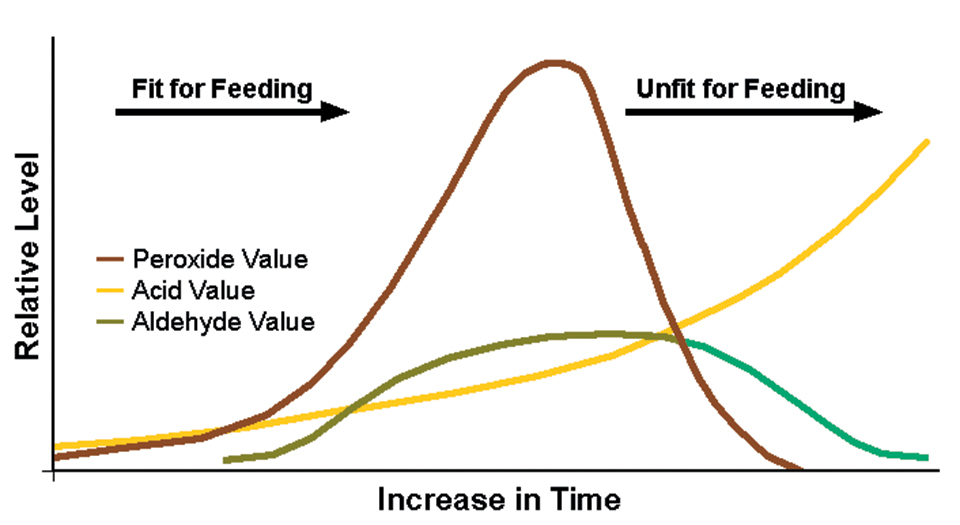

Peroxides increase until a point at which they begin to break down into secondary oxidation products called aldehydes, which can be measured using the anisidine value test. At this point, the quality of feed or feed ingredient becomes suspect. Aldehydes eventually decompose into short-chain volatile fatty acids, which are measured in the OSI fat stability test. Feeds and feed ingredients are not fit for use if oxidation is allowed to progress to this point (Fig. 2).

Antioxidant applications

The production of high-quality fishmeal revolves around management of the catch, the freshness of the product before processing, gentle processing conditions, consistent use of effective antioxidants, and long-term management of the finished meals.

Cooking the raw material before enzymatic degradation begins is essential to the manufacture of meal with high nutrient value. Application of an effective antioxidant like ethoxyquin, both prior to cooking and top dressing after the coolers, provides the best protection against oxidation and insures the quality of fishmeal products during storage.

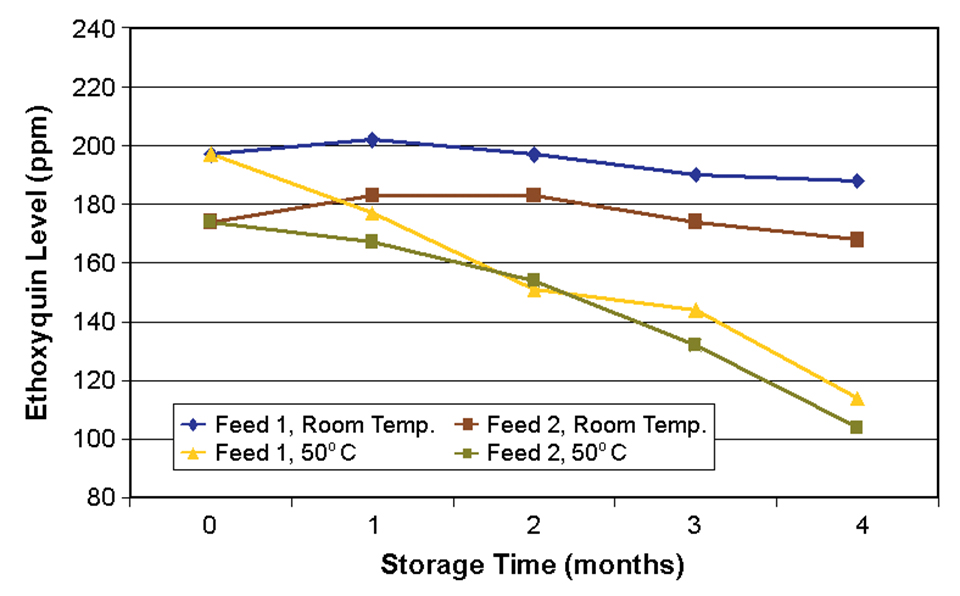

As antioxidants protect against oxidation during long-term storage, their concentrations decrease as the antioxidants are consumed, especially if stored at elevated temperatures (Fig. 3). So it is important to insure that adequate levels of antioxidants are added to account for consumption during storage and transport.

Application of ethoxyquin can also be done at feed mills. Preferably, it should be added to the incoming ingredients, but if quality control programs recommends it, additional ethoxyquin can be added to the mixers. During production, a certain level of antioxidant is consumed as the product goes through pelleting and extrusion, so an adequate level of antioxidant must again be added to account for consumption through the processing steps and storage at elevated temperatures.

Although numerous products have been tested, including a variety of “natural” compounds, ethoxyquin is the most effective antioxidant yet identified for the preservation of finished cooked products. On both cost and absolute inclusion level bases, ethoxyquin remains the preferred antioxidant for effective stabilization of fishmeal and fish oils destined for animal agriculture. Inclusion rates for ethoxyquin in fishmeal should average 750 ppm but be adjusted based on the fat content of the harvested fish, as well as the type of process controls used during cooking, grinding, cooling, packaging and storage.

Conclusion

Oxidation can have negative impacts on feed ingredients and ultimately the performance of the animals that consume the oxidized feed. The oxidation process can be suppressed with proper processing techniques and the effective use of antioxidants. Quality can be monitored using a variety of assays. However, those focused on peroxide generation and oxygen consumption are consistent quality indicators.

Antioxidant applications should be as early as possible at rates that counteract the negative effects of oxidation. When added to feed at 125 ppm, and to meals, fats, and oils at 500 to 1,250 ppm, ethoxyquin provides effective protection against oxidation in feed and feed ingredients.

(Editor’s Note: This article was originally published in the October 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

John T. Andrews

Novus International, Inc.

#20 Research Park Drive

St. Charles, Missouri 63304 USA -

Andrew F. Giesen, Ph.D.

Novus International, Inc.

#20 Research Park Drive

St. Charles, Missouri 63304 USA -

Fredrick R. Scott

Novus International, Inc.

#20 Research Park Drive

St. Charles, Missouri 63304 USA

Tagged With

Related Posts

Aquafeeds

A new nutrient for aquaculture, from microbes that consume carbon waste

Biotechnology firm NovoNutrients aims to produce a line of nutraceutical aquafeed additives as well as a bulk feed ingredient that can supplement fishmeal. Its process includes feeding carbon dioxide from industrial gas to a “microbial consortium” starring hydrogen-oxidizing bacteria.

Intelligence

An examination of seafood packaging

Some substances can migrate from plastics and other seafood packaging materials into the product. Even if the substances are not harmful, they can affect the flavor and acceptability of the food.

Aquafeeds

Animal byproduct concentrates useful tools in formulation

With the market volatility of fishmeal, as well as rising sustainability concerns, the aquaculture industry is seeking sources of protein, such as animal byproduct concentrates, to substitute for fishmeal.

Aquafeeds

Animal co-product hydrolysates sources of key molecules in aquafeeds

Key molecules found in animal byproduct hydrolysates show potential for use as functional ingredients in aquaculture feeds. Animal co-product hydrolysates from slaughterhouse waste and rendered animal byproducts present a protein alternative.