Physical characteristics of manufactured aquafeeds influence performance

Although the cost of formulated aquafeeds in shrimp farming represents approximately 60 percent of the operating costs, the actual application and distribution of feed in shrimp grow-out ponds is still mostly done manually. This is accomplished by broadcasting the feed pellets from the levees in smaller ponds and from moving boats in larger ponds. However, feeding methods are in continuous development and significant efforts are looking at the automation of these operations.

This is the case of the automatic feeders that have been developed in recent years. Proper use significantly reduces production costs and improve shrimp growth rates. The results obtained show that automatic feeding helps to improve efficiency and profitability in farmed shrimp production.

Several of the factors influencing the performance of automatic feeders are related to the physical quality of the feeds, the mechanics of solids inside the feeder, and the consequences of the radius of range distribution the feed has around the feeder. Added to this is the need for proper training of the staff that manage the feeders and that control the data or systems.

Therefore, it is important to strengthen the physical aspects involved in automatic feeding. These, together with an adequate nutritional quality of the feed, are a decisive combination to maximize the yield and profitability of shrimp farms. This article, (adapted and summarized from the original publication in Revista Acuacultura – Cámara Nacional de Acuacultura, No. 123, June 2018), describes the importance of the physical characteristics of shrimp aquafeeds for use with automatic feeders.

Hoppers and the mechanical behavior of food

The food storage hopper is an essential component in all aquaculture systems with automatic feeding, as its design impacts the performance of the equipment. A continuous and uninterrupted flow of feed ensures that the designed feeding program is executed correctly and the strategy has the expected results.

A common and traditional way of understanding the flow of a solid in a hopper has been based on the application of the angle of repose. This is a useful indicator to know the fluidity of the material: the lower its value, the easier it will be for the feed to flow through. However, while having an impact on the mechanical behavior of solids within the hopper, the angle of repose is not the only factor. The common statement about the fluidity of a material as a direct function of the angle of repose should be avoided, because most solids show different degrees of cohesion.

In short, the behavior of the material depends on the manner in which the force of flow varies with its state of compaction. For example, a cohesive solid can flow and pour through a hole, but after being compressed, the flow will not develop due to the formation of a cohesive arc over the hole. This would suggest that the loading force at the base of the hopper should be minimized and that the hoppers should not be used with feed at maximum capacity.

Coefficient of friction or internal friction

When the surface of the feed or the wall of the hopper is rough, the fluidity decreases due to the occurrence of the so-called anchoring between particles. This, as well as the friction between the feed and the wall of the hopper, lead to the feed eventually not flowing freely.

This in turn can result in a scenario in which the dosing motor continues to operate, but there is no feed dispersion since it is still adhered to the hopper internal walls. The feeding schedule is impaired, particularly during hours when the conditions are the best to feed. Larger particles tend to flow better than smaller particles; therefore, the size of the feed has a great impact on its levels of fluidity inside the hopper.

Flow types in the hopper

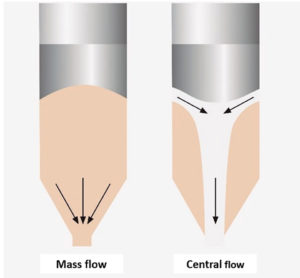

Two flow patterns can occur in a hopper: mass flow and central flow (Fig. 1). In mass flow, the entire bed of solids is in motion when the material is discharged from the outlet. This behavior eliminates the formation of stagnant regions and provides a “first-in, first-out” flow sequence, which in turn provides a more uniform velocity profile during operation. A uniform velocity profile also helps reduce the effects of segregation due to differences in solid size.

On the other hand, during central flow only partial sections of the product move, which means that there is no complete discharge of the hopper. In this way, the stationary material of the first batch is left behind and then it will be mixed with the following batches. Central flow is characterized by a condition in which the side walls of the hopper or the bottom walls are too rough for the material to slide.

The hopper in mass flow solves, in a reasonable way, problems such as the irregular or rapid flow of product, variable residence times and the caking with time and in inactive zones. Fig. 1 shows both types of flow. Obviously, it is desirable that mass flow conditions are generated during the discharge of the feeders.

Parabolic movement and radius of feed range

The range (distance) reached by the aquafeed (pelleted or extruded) in an automatic feeder responds to a logic of parabolic movement, with an initial height. In this type of movement, the initial height (distance between the dispensing motor and the surface of the water) plays a critical role in the range reached by the feed.

Theoretically, if we create a table of feed distance ranges for the parabolic movement of an automatic feeder and represent it in an equation, we find that the range Rm depends on the height (Table 1).

Where:

Rm = average radius of range, with Vo = initial velocity

h = height

g = gravity

A reduction in the average radius of the range translates into less space for animals to feed (Table 1). Considering that the feeding areas occupy 3 to 5 percent of the pond area, and that they harbor a large biomass, this reduction is critical – in terms of space – to provide feed for the shrimp. Such a decrease in feeding space could result in competition and promote, intensify and/or enhance territorial behavior.

Molina, feed characteristics, Table 1

| Height (m) | Avg. radius of range (m) | Covered area (square meters) |

|---|---|---|

| 0.8 | 13.9 | 606 |

| 1 | 14.08 | 622 |

| 1.2 | 14.23 | 635 |

| 1.5 | 14.47 | 657 |

The physical quality and bioavailability of nutrients are, together, the most important factors to maximize the yield of the feed. The raw material used, as well as the process technology, have a great impact on final feed quality. There are several physical parameters that are measured in a shrimp feed, both in the manufacturing line and in the final product.

Particle homogeneity: diameter and length

Feed homogeneity, in terms of diameter and length, is directly related to its utilization. Homogeneity in feed particle size ensures that after capture, the most is made of the feed particle.

Feed size and its influence on feeding has been reported by Obaldo and Masuda (2008), who investigated six diet sizes and their effect on the feeding behavior and growth of juvenile Pacific white shrimp (Litopenaeus vannamei). The results indicated that when shrimp are fed with larger pellets, some of the individuals monopolize the feed and obstruct the feeding behavior of others, and this is significantly different between feed sizes. This shrimp behavior was observed with greater frequency in shrimp fed with 3.0 mm pellets, in comparison to shrimp fed with 0.7 and 1.2 mm pellets, which could result in a considerable variation in size and mortality of the smallest individuals.

From the point of view of the mechanical flow inside hopper, pellet diameter and length play a critical role, because the degree of packing of more homogeneous particles leads to a balance of forces that improves flow.

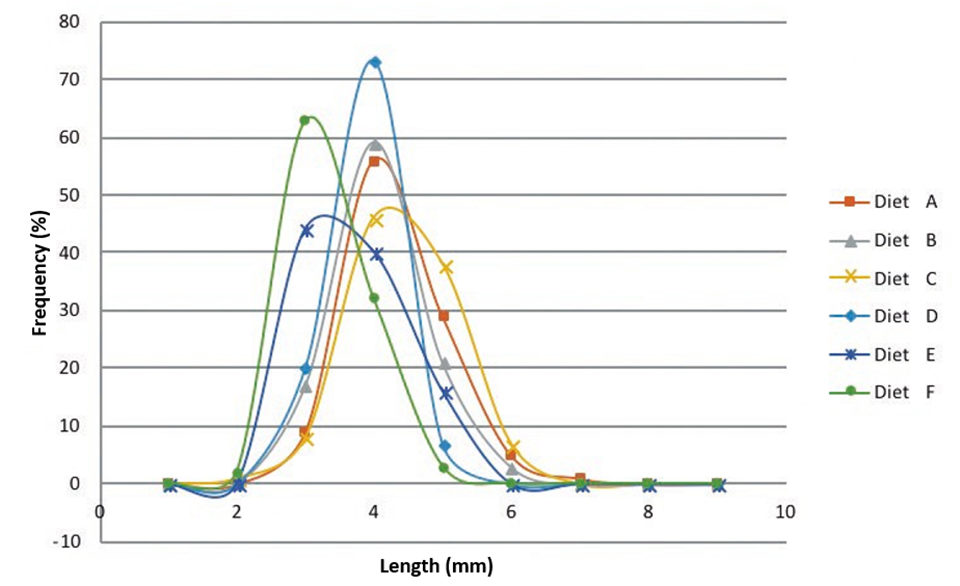

Fig. 2 shows the frequency distributions of the lengths, with significantly lower standard deviations in certain feeds. Note that diet D has a symmetric distribution (an almost perfect bell distribution), while the other diets – A, B, C, E and F – have less homogeneous distributions.

Product homogeneity means a more balanced access to the feed for all animals during conditions of high animal density of animals, typical of feeding areas around a feeder. Mechanically, this also translates into a more uniform and uninterrupted flow, which allows the feeder to dynamically dispense the programmed quantities.

Fines

The fines in the feed constitute losses because they are not used by the animals, and in fact, their decomposition affects water quality. In automatic feeding, the transfer of feed from the feed mill to the shrimp farm warehouse and later to automatic feeder hoppers generate a greater or lesser amount of fines depending on the type of feed.

During transport, while in storage and when dispensed, the mechanical forces that come into play make poorly manufactured feed even more prone to disintegration, with the consequent increase in feed particles that will not be utilized by the cultured animals (Fig. 3A). The accumulation of these fines blocks the exit holes, preventing the normal projection of the feed pellets during automatic feeding. This type of obstruction is even more severe in feeders with V outputs (Fig. 3B). This type of feeders, having exit holes with a small dispensing surface, can become clogged with feed pellets combined or mixed with fines.

Table 2 shows several physical parameters of the feed that are directly related to the performance of the automated feeder. An interesting case is related to the humidity of the product. Above the range mentioned in Table 2, specifically at a humidity of 11.8 percent, a greater tendency for blockages is observed due to lumping. The lumps obstruct the outputs of the feeder, preventing normal feed projection and distribution.

Molina, feed characteristics, Table 2

| Parameter | Value |

|---|---|

| Pellet harness (kg f/cm2) | 1.1 – 1.8 |

| Fines (%) | up to 0.3 |

| Durability index (%) | 98.2 – 99.7 |

| Coefficient of variation of length (%) | 9.5 – 20.0 |

| Density (g/mL) | 1.16 – 1.21 |

| Coefficient of variation of diameter (%) | 4.7 – 6.9 |

| Moisture (%) | 9.8 – 11.15 |

| Pellet volume (mm3) | 3.6 – 19.0 |

With higher levels of humidity, such as 12 percent, the greatest problems with blockages due to lumps have been reported – up to 5 blockages when dispensing a 25 kg bag of feed. For this reason, external liquid addition to the feed prior to distribution by automatic feeder is not recommended due to the caking effects that have been observed in tests when adding various liquids to the feed after its manufacture.

Conclusions

The introduction of automatic feeding systems generates the need to improve the physical quality of aquafeeds. At the same time, it is necessary to adapt these systems to a new reality where the feed properties determine, to a large extent, the performance of the equipment and, ultimately, the feeding strategy. On the other hand, the physical and design characteristics of the feeder also directly affect performance.

The interactions of solids, understood as flows and jams, are complex. In specific environments such as in aquaculture production, the physical-mechanical properties of aquafeeds have particularities that merit attention due to a number of possible issues. The relative humidity, storage time, the level of the material, and feed humidity and temperature are other variables that are in play and that have been studied only superficially. Therefore, more studies are necessary in order to mitigate any issues created and to better understand the guidelines governing their behavior.

The distribution of feed through automatic devices presents multiple challenges that are closely related to the type of food, size, shape, dispensing speed, range and others. All of these are physical characteristics that determine the performance of the feeder and ultimately, make the difference compared to a traditional feeding strategy.

The characteristics, both of the feeder and of the feed, that lead to a feeder failure or blockage are related in one way or another to the forces of compaction and friction. Minimizing these issues using devices that reduce the force on the bottom of the hopper should be done and monitored in such a way that the designed feeding program can be implemented to achieve the best possible performance.

References available from first author.

Authors

-

Cesar Molina, Ph.D.

Research and Development Manager

Skretting Ecuador

Durán, Ecuador -

Manuel Espinoza, M.Sc.

Research and Development

Skretting Ecuador

Durán, Ecuador

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Analyzing the hydrostability of shrimp feeds

The physical integrity and nutrient leaching of shrimp aquafeeds are important aspects in their quality control. The water stability of shrimp aquafeeds is often evaluated in various subjective manners. This analytical procedure provides a baseline for the aquafeed manufacturer to assess product quality.

Aquafeeds

Extrusion supports fortification of specialized shrimp feeds based on vegetable proteins

Extrusion manufacturing of aquafeeds has recently seen advances in several areas. The development of new die technology has multiplied hourly output.

Aquafeeds

Best practices for optimum shrimp feeds

Producing a consistent shrimp feed pellet requires that all ingredients are processed properly and monitored through proper in-line quality assurance.