The simpler the system, the more effective

It was 5:14 a.m. when my cell phone rang with the dreaded call feared by all aquaculture managers: “This is Sensaphone … The electricity is off! The electricity is off!” I was dressed and out the door in less than 10 minutes. Breaking every speed limit on the way, I burst through the greenhouse doors, hoping the fish were not floating on the surface for lack of oxygen.

Without electricity, the regenerative blowers were off, the circulation pumps were off and the overhead lights were off. Luckily, the flashlight was where it was supposed to be and even worked. The question was: Were the fish still alive after 20 minutes without electricity?

Much to my delight, the answer was not only “yes,” but the dissolved-oxygen levels in the tanks were actually higher than normal, and the fish, although spooked due to lack of circulation, were fine. How was this possible?

A simple backup system turned on an oxygen diffuser in each tank as soon as the electricity went off and stayed on until the electricity went back on. For a small investment in equipment, the backup oxygen system not only worked when needed, but saved the day – and the fish.

Backups essential

Visits to research and commercial aquaculture facilities often find no backup systems or systems that have not been installed. Yet, the very survival of the research programs, the endangered species or the commercial venture rests on the successful grow-out and high survival of the cultured species.

Why are the monitoring and backup systems not operating? Typical answers: “We haven’t gotten around to it.” “The money ran out before we could get to them.” “The ‘specialist’ left and no one knows how to turn things on.”

As a result, we read at least several times a year about the loss of all the fish in a facility due to something as simple as a loss of power. Or if the fish are not completely lost, they are stressed so much that after several weeks they suffer from stress-induced diseases.

Minimize impacts

Backup systems do not have to be sophisticated, complicated or expensive. In fact, the simpler they are, the more likely they are to work.

For intensive recirculating aquaculture systems, failure is not an option. Since the loss of power is one of the most common emergency situations, at least two quick responses are recommended when the electricity goes off.

The first is immediate notification of at least two people through the use of an inexpensive, off-the-shelf automated phone dialer that can be purchased from several manufacturers for U.S. $100 to $500. At a minimum, these units dial out to three or four phone numbers and announce the emergency condition so that someone can respond as quickly as possible. In addition, they usually have several on/off switch inputs that activate an alarm locally and call someone to announce the alarm condition.

The second response is to minimize the impacts of the emergency situation on the aquaculture system. A backup generator with a power transfer switch that automatically starts when the power goes off is the best solution to power outages, but often too expensive to purchase and requires routine maintenance and upkeep.

Emergency oxygen

For a quick response to a power outage, one option is to have several high-pressure cylinders of oxygen that are connected to an inexpensive normally open oxygen-rated solenoid valve that is simply plugged into a wall outlet. When there is power, the solenoid is energized and closed. When the power goes out, the solenoid opens and oxygen flows. A simple oxygen manifold then directs oxygen to an oxygen diffuser in each aquaculture tank. This type of emergency oxygen system can be set up for about U.S. $250.

The system is simple to build and install. In addition, this set-up can be used when sorting or moving fish to add a little extra dissolved oxygen to minimize stress.

In practice, one issue became apparent when Hurricane Gustav struck New Orleans last year. At my aquaculture facility, the electricity stayed on, but the aeration system didn’t. And even though I received a call reporting the low air pressure, I was several hundred miles away and unable to respond. The solution to the problem was to add a U.S. $30 air pressure switch and relay to the oxygen backup system, so that if the aeration pressure failed, the oxygen solenoid would open and allow flow to the tanks.

Water loss

Loss of water is another major emergency situation. Pipes break, rubber couplings come loose and drain lines may be left open. I once left a hose in a tank over the weekend and all the fish were on the floor on Monday morning. Luckily, they were tilapia and I just put them back into the tank.

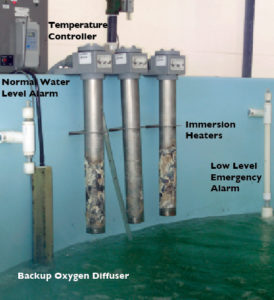

Water level is one of the easiest parameters to monitor using a float switch, which costs U.S $10 to $20. Two float switches wired in series can be used to monitor both low and high water levels, so that if one is activated, a local audible alarm goes off. This allows maintaining water levels in tanks within a very narrow range.

With the addition of another low level float switch installed at a depth of 30 to 40 cm and connected to a phone dialer, small changes in water level are reported locally for quick response, and any significant drop in water level is phoned to the staff. This minimizes false alarms early in the morning due to minor water level changes. As an added feature, the deeper float switches can act as a safety shutoff for submerged heaters in the event of a dramatic drop in tank water level.

Redundancy, redundancy

Getting back to my story of how backups saved the day … it was 5:34 a.m. and the dissolved-oxygen levels were fine, but there was still no power, and the transformer on the pole down the street was still arcing and flashing. Several portable backup generators on site were easily rolled next to the greenhouse for powering the regenerative blowers for aeration. Of course, as Murphy will remind you, something went wrong.

Even though we try to test these generators regularly, I was unable to start the primary generator. But like all good backup plans, we had a backup to the backup, and our second generator started without any problem. With a couple of extension cords, aeration and circulation were restored in the research greenhouse within a very short time. The only thing overlooked was a provision for emergency lighting so we could see what we were doing. That will be rectified in the near future.

Moral: plan for the worst

The moral of this tale is to expect the worst and plan for it, but above all do not think that backup systems are too expensive or too much of a hassle to install. Before stocking any fish, have a minimum of a backup oxygen system and portable generators available for emergency situations, plus a phone line. You may not have to plan for hurricanes, but even a burned-out transformer can lead to a significant, unplanned career change.

(Editor’s Note: This article was originally published in the March/April 2010 print edition of the Global Aquaculture Advocate.)

Authors

-

James M. Ebeling, Ph.D.

Aquaculture Systems Technologies, LLC

108 Industrial Avenue

New Orleans, Louisiana 70121 USA[109,111,99,46,115,114,101,116,108,105,102,100,97,101,98,64,115,101,109,97,106]

-

Paul Hightower

Aquaculture Systems Technologies, LLC

108 Industrial Avenue

New Orleans, Louisiana 70121 USA

Tagged With

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Intelligence

A land grab for salmon (and shrimp) in upstate New York

The operators of Hudson Valley Fish Farm see their inland locale as a pilot to prove that land-based fish farming, located in close proximity to major metropolitan markets, can be successful.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.