Biofilter choices can achieve nearly any desired water quality

The heart of a recirculating system is its biofilter. The heterotrophic and autotrophic bacterial communities supported within the biofilter naturally process organic wastes and provide biologically stable water that can be recycled for months. When choosing a biofiltration system for commercial aquaculture production, the efficiency of both the technology and substrate are very important, for they define the size, cost, and energy usage of the most expensive treatment component in recirculating systems.

The heart of a recirculating system is its biofilter. The heterotrophic and autotrophic bacterial communities supported within the biofilter naturally process organic wastes and provide biologically stable water that can be recycled for months. When choosing a biofiltration system for commercial aquaculture production, the efficiency of both the technology and substrate are very important, for they define the size, cost, and energy usage of the most expensive treatment component in recirculating systems.

Biofilter types

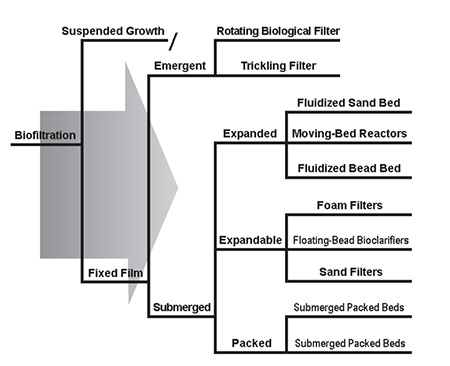

Several types of biofilters must be considered when designing a recirculating system. Figure 1 presents the decision tree that confronts aquaculture engineers as they select the best biofilter for a given application. Successive decisions at each junction lead to the filter that will perform with the best reliability and cost effectiveness.

Attached or suspended

The first juncture forces a choice between the two fundamental approaches to bacteria culture. Suspended growth processes depend on heterotrophic bacteria – those that utilize only organic materials as food. These bacteria grow in small, suspended clusters, usually referred to as biofloc. Only old bioflocs are capable of supporting the nitrification process, so aquaculturists on this pathway ultimately end up in a subcategory known as extended aeration. This approach, which requires the addition of significant amounts of oxygen, is similar to the aerated pond work found in intensive tilapia and shrimp systems. Suspended growth systems are easiest to operate with the relatively high levels of biological oxygen demand and total ammonia-nitrogen (TAN) normally associated with very high stocking densities. Most aquaculture engineers make a turn toward fixed-film biofilters at the first juncture, because these filters are more stable at low substrate concentrations.

Fixed-film biofilters

Fixed-film biofilters basically provide a surface area to culture bacterial films. Bacteria are not particular about their growth medium and can subsist on virtually any rock, shell, plastic, or sand surface provided. Fixed-film processes can be distinguished by the strategy used to provide oxygen, surface area per unit volume, and means to handle excessive bacterial growth. Biofilms can be thick or thin, depending on the amount of food available and biofiltration strategy used. In moderately and heavily loaded systems, thick biofilms that develop on biofilter media must be managed to optimize water quality. Thin film reactors can provide very high water quality in lightly loaded systems. However, in heavily loaded systems, their efficiency becomes limited. These characteristics, in turn, determine the useful zones of application for each filter.

Submerged or emergent

Aerobic filters need oxygen. If enough oxygen can be provided to the biofilm in the water transported to the filter, choose a submerged filter. Otherwise, enter the realm of emergent filters. Emergent filters use a cascading mixture of water and air to assure that high oxygen levels are maintained at the surface of the biofilm. Trickling filters disperse water over a column packed with biofilter media. Rotating biological contactors – sometimes called wet/dry filters – use a more mechanical approach. They slowly rotate in and out of a tank of water, always keeping the media wet, but providing supplemental aeration.

Emergent filters

Emergent filters are capable of extremely high areal conversions of TAN (grams of TAN converted per square meter of surface), but are limited by low specific surface area (square meters of biofilm per cubic meter of unit volume). As a result, emergent filters can be 5 to 10 times larger than the submerged alternatives, and care must be taken with some media types to prevent possible clogging. These filters provide secondary benefits in the form of aeration and carbon dioxide stripping. They are best applied to heavily loaded systems, where their ability to deliver oxygen to the biofilm can result in some benefit.

Submerged filters

Submerged filter advocates note that the fish in recirculating systems live on the influent side of the filters, and TAN levels must be kept very low. They argue that TAN diffusion into biofilms, not oxygen diffusion, limits biofiltration performance. Submerged filter advocates tend to focus their attention first on maximizing specific surface area, and then on biofilms and solids management, in order to enhance TAN diffusion rates.

Submerged packed beds

Perhaps the oldest of the biofilters, submerged packed beds consist merely of a bed of submerged media through which recirculating water is passed. These filters generally have no biofilm or solids-management capabilities, and little attention is given to specific surface area considerations. These filters have been used with great success in seafood-holding systems, lightly loaded aquaculture systems, display aquaria, and the like. The large, inexpensive filters do a great job until they are overfed and pushed into a zone of net positive bacterial growth that renders them useless, as water can no longer penetrate the filter. Such shortcomings of submerged packed beds have been addressed by filters that can manage the solids accumulation issue.

Expandable granular filters

A backwashing mechanism distinguishes expandable granular filters from other types. Expandable granular filters, which include fine sand filters, gravel filters, and bead filters, share a similar backwash strategy that allows them to operate across a broad range of functions. This choice controls water loss and greatly influences the ease with which the filters’ biofilms can be manipulated. Expandable granular filters have the unique ability to operate as mechanical filters, biofilters, or bioclarifiers. However, their effectiveness in these three areas varies greatly.

Fine sand filters

Fine sand filters are principally used as mechanical filters in most applications, but contribute some nitrification when used in recirculating systems. These filters make poor biofilters in most commercial applications, as biofilm development rapidly disables the washing mechanism. All sand and gravel filters require high flow rates to initiate their expansion, which also leads to high water losses during backwashing. These water losses can impede biofilm management strategies that improve the biofilter capabilities. Sand filters are widely used as clarifiers for display aquaria, influent mechanical filters in aquaculture systems, and bioclarifiers in very lightly loaded recirculating systems. Coarse sand and gravel media have been used with some degree of success, because they have sufficient abrasive capabilities to knock off biofloc and prevent the caking problems that plague the finer sand beds.

Floating-bead filters

Floating-bead filters possess virtually all the attributes of the sand and gravel filters while reducing or eliminating both the biofouling and water loss issues. Depending on the application, bead filters can be used effectively as mechanical filters, biofilters, or bioclarifiers, where they simultaneously capture solids and act as biofilters. The units’ backwashing mechanism and frequency are employed as a bio-film management tool. Thus, well-managed units are capable of producing volumetric TAN conversion rates that are highly competitive with other biofiltration formats. Additionally, water loss for these filters ranges from just over 1 percent to 10 percent of the backwashing requirements for equivalent gravel filters.

Expanded biofilters

Expanded biofilters that keep sand or beads continuously expanded will not capture solids, but are used as highly effective biofilters. Fluidized sand bed biofilters keep sand particles evenly in suspension so the media acts like a fluid. The extremely high specific surface area of the fine sand media allows the filters to operate effectively at low ammonia levels of less than 0.1 mg-N per liter, even when subjected to adverse conditions such as low pH. Fine sand particles are best suited for lightly loaded systems where very low TAN concentrations are required. For example, they have been used with considerable success in the ornamental fish industry. The units, however, tend to lose sand when substrate levels increase and have limited ability to abrade biofilm.

Coarse sand

Coarse-sand filters still have excellent specific surface areas, are highly abrasive, and are well suited to heavier loading capacities. Coarse-sand fluidized beds support very high TAN conversions, but usually only at elevated ammonia levels greater than 1.5 mg-N per liter. At low substrate concentrations, the biofilm is overabraded.

Continuous operation needed

One of the disadvantages of traditional fluidized beds is their inherent need to be continuously operated. For example, if the power is cut off for an extended period, the sand bed will collapse and turn anaerobic, killing off the beneficial bacteria required to process waste. The beds also have a tendency to clump, if allowed to settle. Therefore, it is crucial to have an uninterrupted power supply with backup, and to choose fluidized beds that can be easily restarted.

Moving-bead reactors

Moving-bead reactors use floating plastic media in an unpressurized tank to overcome some of the shortcomings of traditional beds. Continual internal mixing is induced by a combination of water circulation and air sparging. Balance between abrasion and biofilm growth is achieved by media shape selection and the degree of air sparging. This emerging filtration format shows growing promise because it can operate across a wide range of substrate concentrations, displays excellent conversions, and has very low head requirements that minimize the electricity needed.

Plastic bead beds

Beds of plastic beads – some as small as 1 mm in diameter – can also be fluidized. These generally have good specific surface area characteristics. The constant movement of the beads is induced by airlifts, direct hydraulic fluidization (in the downward direction), or mechanical means. Constant fluidization continually abrades the biofloc, preventing biofouling problems. These units have an extended history of effectiveness.

Conclusion

Biofiltration technology has evolved to the point where filter choices can achieve nearly any desired water quality in aquatic systems. But with increasing water-quality demands come increased equipment costs. The decision on which biofiltration format to choose depends on the application in which it will be used, the cost of the system relative to the desired water quality, and the additional filtration components required to complete the recirculating system. Choosing the most appropriate biofiltration system is key to realizing the economic benefits of recirculating systems.

(Editor’s Note: This article was originally published in the June 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Ronald F. Malone, Ph.D.

Deputy Director

Louisiana State University

Institute for Ecological Engineering

Engineering Lab Annex Building

100 ELAB

Baton Rouge, Louisiana 70803 USA

Tagged With

Related Posts

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.

Responsibility

Ammonia nitrogen dynamics in aquaculture

The major sources of ammonia in aquaculture ponds are fertilizers and feeds, and problems with high ammonia are most common in feed-based aquaculture.

Responsibility

Automated temperature-controlled recirculation systems

A temperature-control system with a central chiller was found to enhance chilling and research capacity over a system with multiple unit chillers because replicating experiments in a single process control system minimized variations in the temperatures and chilling rates in the individual tanks. Temperature-holding experiments found slight differences at different temperature levels.