Emulate the development of biosecurity in the poultry industry

Biosecurity has been key to the success of the modern poultry industry in increasing production and decreasing disease losses. The aquaculture industry has an opportunity to follow this example to become more competitive and environmentally friendly.

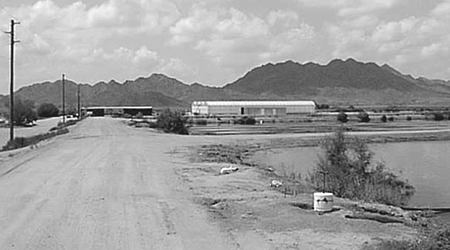

Geographic isolation is often used in the poultry industry to reduce the exposure of breeding stocks to potential pathogens. The shrimp industry has also taken advantage of geographic isolation to maintain Specific Pathogen Free (SPF) populations of Pacific white shrimp in the Hawaiian Islands, or in the Arizona desert (Fig. 1). Nevertheless, geographic isolation, in itself, is not a complete safeguard. This painful lesson was learned in Hawaii in the late 1980s, when non-indigenous IHHN virus decimated stocks of L. stylirostris in intensive raceways operated by Marine Culture Enterprises.

Effective biosecurity requires environmental isolation in a closed system, such as the recirculating aquaculture systems (RAS) used to culture cephalopod species (squid, cuttlefish and octopus) through multiple generations at the University of Texas Medical Branch in Galveston, Texas, USA.

Design of recirculating aquaculture systems

The design of an environmentally isolated RAS depends on the actual requirements of the animals to be cultured. Freshwater systems generally use water derived from isolated wells, while marine systems use artificial sea salts. This water is recirculated through a variety of filtration components so it can be re-used. It is not practical to completely close RAS to all external inputs, since food and makeup water are required. Most RAS in operation today add more than 10 percent system water volume per day.

Biosecure, closed systems can be managed manually or by automated means. For seedstock and broodstock systems, manual intervention is needed for monitoring of animals. However, control of temperature, lighting, and some feeding and filtration components can be automated effectively.

For closed recirculating production systems, most of the functions, including the filtration system, should be automated. To offset the higher capital costs of system construction, the goal is to increase production, and reduce labor and disease losses.

Seedstock and broodstock biosecurity

The source of seedstock for biosecure production systems must be an SPF hatchery. While few hatcheries rely completely on closed systems, some are geographically isolated and many are increasingly utilizing recirculation technology.

Maturation systems are implementing RAS because of their low biomass, need for high water quality, and improved ability to constantly monitor mating and spawning behavior. The advent of environmentally isolated, biosecure hatcheries and maturation facilities will mirror the compartmentalization developed for modern poultry production.

Biosecurity of feed

Environmentally closed RAS should use biosecure food sources that cannot be vectors for transmission of disease. The marine animal meals used in a feed should be closely scrutinized as to location of origin and processing technology. For example, the use of salmon offal in salmon feed without proper heat processing would defeat the whole biosecure concept. Likewise, use of fresh squid or clams derived from an area with high shrimp viral infection, or from a processing plant that concurrently handles potentially infected shrimp, would be an unneeded risk.

Larval-rearing systems represent a special problem since algae and artemia cultures are frequently sources of contamination. Biosecure algae and rotifer cultures can be established and maintained using aseptic techniques. artemia cysts are probably the greatest worry for crustacean culture, particularly marine shrimp. Sterilization and irradiation techniques may solve this potential problem in the near future.

Conclusion

The advent of biosecure RAS has been spurred on by recurring aquaculture diseases worldwide. The main advantages of RAS technology are its environmental isolation from natural waters and disease vectors, increased monitoring and control, and elimination of negative environmental impacts such as effluents and disease transmission to natural populations. The aquaculture industry should be able to emulate the development of biosecurity in the poultry industry and reap the same increases in productivity and sustainability.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Phillip G. Lee, Ph.D.

Director

National Resource Center for Cephalopods

University of Texas Medical Branch

Galveston, TX, USA

Tagged With

Related Posts

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Intelligence

Food irradiation, part 1

In 1997, the United States Food and Drug Administration approved irradiation for meat, which can kill or inactivate 99.9 percent of Salmonella and E coli.

Health & Welfare

Aquamimicry: A revolutionary concept for shrimp farming

Aquamimicry simulates natural, estuarine production conditions by creating zooplankton blooms as supplemental nutrition to the cultured shrimp, and beneficial bacteria to maintain water quality. Better-quality shrimp can be produced at lower cost and in a more sustainable manner.

Health & Welfare

Biosecurity practices on fish farms need beefing up

Biosecurity measures and preventive strategies are essential in any biological production chain. Properly planned and implemented biosecurity programs will enhance animal health, production and economics.