MicroSynbiotiX developing versatile oral vaccines intended for wide range of species

To break aquaculture’s costly ties to antibiotics in its ongoing battles with infectious diseases, preventative measures must be developed. Vaccines have proven effective, particularly in Norway’s farmed salmon sector, which has been able to phase out antibiotics. But injecting fish individually is a labor-intensive, costly endeavor that only producers of large, high-value fish like salmon, sea bass and trout can afford.

The race to bring oral vaccinations to the global aquaculture market is on. MicroSynbiotiX, a biotechnology startup based in Ireland with offices in San Diego, Calif., believes it has a leg up. The company is employing the power of transgenic microalgae to make it cheaper and easier for aquaculture producers to administer vaccines to fish via their feed.

The company, founded in 2016, offers two products: an algae-based oral delivery platform for fish vaccinations, as well as a function feeder for shrimp designed to combat a variety of viral disease outbreaks in shrimp farms. MicroSynbiotiX, which presented at the Global Aquaculture Alliance’s GOAL conference in Dublin, Ireland, last month, has so far raised more than €1 million ($1.2 million) in venture capital funding.

“Our goal is to reduce the stock losses in the aquaculture industry,” said MicroSynbiotiX CEO Simon Porphy. “The industry is facing $10 billion worth of stock losses each year, and also uses a lot of antibiotics and anti-microbial compounds, which are not sustainable in the long run.”

Chile illustrates his point. The bacterial disease Piscirickettsiosis is common there, and as recently as 2014 salmon farmers were using 1.2 million pounds of antibiotics annually to treat a crop of less than 900,000 metric tons of fish. That was up 25 percent from the year before, as bacterial infections, which can cause lesions and hemorrhaging, ran rampant in the world’s second-largest salmon producer.

The world’s top producer, Norway, on the other hand, has been phasing out the use of antibiotics in its aquaculture industry since the 1990s. In 2015, the country produced 1.3 million metric tons of salmon, all of which were virtually free of antibiotics.

Norway doesn’t have the same bacterial challenges as Chile does with Piscirickettsiosis, for which there is currently no effective vaccine, but its success in reducing its dependence on antibiotics – the country embraced antibiotic usage in the 1980s, peaking in 1988 with 50 metric tons of the drugs being used to treat 500,000 metrics tons of fish – is a model that the rest of the world is beginning to adopt.

Simplifying vaccines

The MicroSynbiotiX solution involves new delivery mechanisms for bacterial vaccines that can be used for a variety of different fish species, thereby reducing the need for antibiotics and making disease management simpler and more sustainable, said Porphy.

By adjusting dosages and feed formulations, the company can make vaccines that are essentially universal and can treat many different kinds of fish. Its efforts are currently focused on shrimp, for which microalgae is a natural part of the diet and for which there is no oral delivery strategy currently available.

Porphy says the company plans to extend to other species as it scales up.

“We will be able to develop bacterial vaccines, not just for salmon, but low-value fish stocks like tilapia,” Porphy said. “As a result, they would be able to maintain their water quality in the farms much better than by using antibiotics. Excess use of antibiotics can lead to poor water quality, which in turn can lead to disease outbreaks, as poor water quality would put a lot of stress on the immunology of the fish.”

An advanced technique

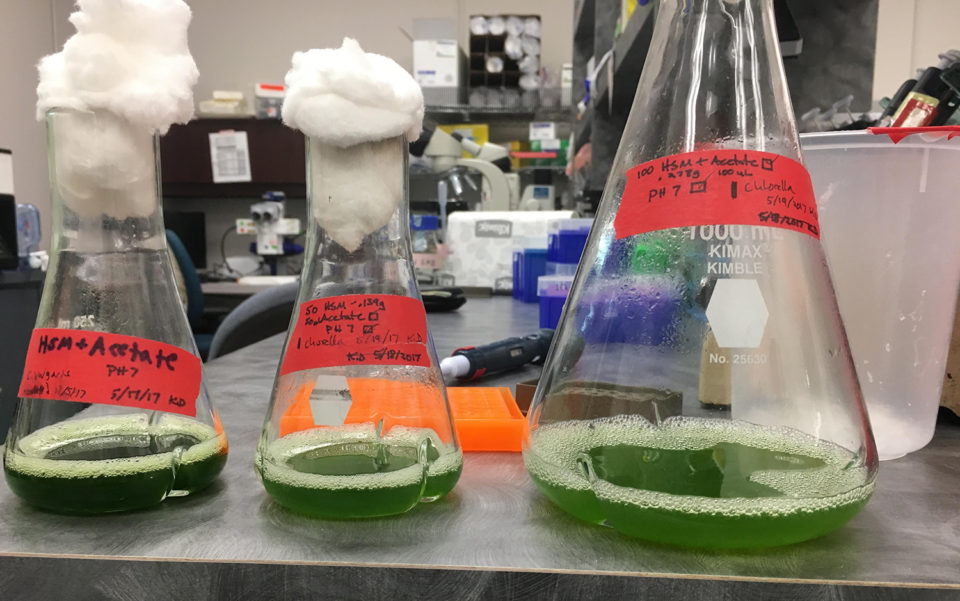

It all comes down to genetic modification, according to Porphy. MicroSynbiotiX’s technology is built on using recombinant DNA technology to integrate vaccine DNA into microalgae DNA directly. Once the vaccine information is integrated into the strand, the microalgae itself has access to a new set of data that it can use to manufacture the vaccine, producing it within the microalgae biomass.

In this way, the algae is effectively being trained to produce a specific vaccine and keep it safe within its own cells.

From there, MicroSynbiotiX further grows each particular clone of microalgae in large bioreactors, allowing the progenies – or offspring – of the original clone to grow into large concentrations of biomass, all encapsulated with the vaccine DNA. The microalgae is then harvested, freeze-dried and then transported to where it is needed for use.

“This is another important change,” Porphy said, “as many farms in Thailand, Vietnam don’t have access to cold storage units in remote locations. Unlike conventional vaccines, which would require cold storage units for storage as well as for transportation, making transportation of expensive vaccines to remote locations incredibly difficult, that wouldn’t be the case for us.”

It could be the game-changer that fish farmers have been waiting for, one that allows them to manage their facilities and maintain fish health holistically, rather than reacting with antibiotics when problems arise. This will save money, time and fish.

“This is more like an insurance policy for the fish farmer,” Porphy said. “If you don’t vaccinate your fish, or if you don’t provide any immunostimulants to your shrimp, the farmer will likely end up losing their entire stock. But if the farmer spends about 3 percent of the total feedstock cost on buying our product, he could potentially save at least 50 percent to 70 percent of his fish stocks from getting wiped out by a viral disease outbreak. It’s a simple insurance policy.”

Author

-

Tim Sprinkle

Tim Sprinkle is a writer based in Denver, Colo. His work has appeared in Wired, Outside and many other publications, and he is the author of the 2015 book, “Screw the Valley: A Coast-to-Coast Tour of America’s New Tech Startup Culture.”

Tagged With

Related Posts

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Innovation & Investment

Aquafeed ingredient AlgaPrime wins GAA Innovation Award

A proliferation of alternative feed ingredients has allowed aquaculture to extend the natural resources it depends on. AlgaPrime, packed with the long-chain omega-3 fatty acid DHA, is being recognized as a game-changing innovation for aquaculture feeds.

Aquafeeds

Bridging the omega-3 gap with methane, microalgae

Innovation is leading to new ingredient options for renewable sources of omega-3 fatty acids. But Replicating long chain fatty acids is a tall order, Advocate contributor Lisa Duchene discovered.

Health & Welfare

Big shoes to fill: Dhar takes reins at shrimp pathology laboratory

Arun Dhar, Ph.D. will attempt to fill the “big shoes” of Dr. Donald Lightner at the University of Arizona’s Aquaculture Pathology Laboratory, where the shrimp disease EMS was diagnosed.