Small-scale systems could produce local specialty products for regional markets

Over the past few years, the authors have been involved in several large-scale aquaculture engineering design projects for the production of marine shrimp, tilapia, cobia and sturgeon with production goals ranging from 500 to 2,000 metric tons per year. Engineering designs were generated and submitted to the project initiators, suitable sites were selected for the production facilities and then the projects were terminated before inception by the companies’ chief financial officers. The reasons were primarily the large capital investment required for the initial start-up and the long delay before significant cash flows would be seen.

Although large-scale aquaculture projects could play a significant role in filling the demand for seafood over the next decades, there still exists a substantial opportunity for “boutique” aquaculture production systems to fill gaps in the fresh seafood market. These small-scale production systems could produce localized specialty products for regional markets with a more manageable capital investment.

Spotted sea trout

For example, in the United States, the spotted sea trout (Cynoscion nebulosus) is historically one of the most important species in the cuisines of New Orleans and southern Louisiana, the Alabama and Mississippi coasts, and western Florida. It is prized for its delicate flavor, but because of its delicate structure, fresh product is preferred.

Historically, the supply of spotted sea trout was provided by inshore commercial anglers. The commercial fishery peaked in 1973 with an annual catch of over 3,400 metric tons, but due to changing regulations and an increase in the importance of recreational fishing, the commercial catch has steadily declined to only 14 metric tons in 2006. The economic value of the commercial fisheries declined from over U.S. $3 million in 1983 to less than $67,000 in 2006.

Today, no viable commercial fishery for spotted sea trout exists in the Gulf of Mexico. A domestic mariculture industry could fill the gap in the fresh seafood market, keep seatrout on regional menus year round and provide a platform for sound economic development in coastal communities that are experiencing declining maritime opportunities.

Design project

Present-day recirculating aquaculture system technologies along with breakthroughs in live feed production can make commercial production of spotted sea trout economically viable. Thus, the spotted seatrout is an excellent species to use as a demonstration model for a boutique commercial marine aquaculture operation.

In 2008, a design project was initiated in cooperation with the University of Southern Mississippi’s Gulf Coast Research Laboratory to validate a demonstration-scale, land-based, recirculating production system capable of producing 50 metric tons of spotted sea trout per year at full production.

Conceptual design goals

A system design summary is provided in Table 1. The production goals for the design were for a modest-scale demonstration facility that could be located near the markets in an industrial park or other commercial setting. Weekly production goals were approximately 1,000 kg live weight at a target fish size of 500 grams. The total grow-out time was estimated using the fact that for most fish, growth rate in terms of change in length is relatively constant over the entire grow-out period.

Ebeling, System design summary, Table 1

| Growth Stage | Weeks In Stage | Final Length (cm) | Final Weight (g) | Final Biomass (kg) | Number of Tanks | Diameter (m) | Depth (m) | Tank Volume (m3) | Final Density (kg/m3) |

|---|

Growth Stage | Weeks In Stage | Final Length (cm) | Final Weight (g) | Final Biomass (kg) | Number of Tanks | Diameter (m) | Depth (m) | Tank Volume (m3) | Final Density (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|

| Quarantine | 6 | 3.3 | 1.2 | 7.1 | 3 | 1.22 | 0.76 | 0.71 | 10.0 |

| Fry/nursery | 4 | 9.2 | 5.4 | 25.4 | 2 | 1.83 | 0.64 | 1.68 | 15.1 |

| Juvenile | 12 | 19.9 | 55.0 | 117.0 | 12 | 2.44 | 0.91 | 3.90 | 30.0 |

| Fingerling | 12 | 30.7 | 202.0 | 407.0 | 12 | 3.66 | 1.07 | 10.20 | 40.0 |

| Growout | 12 | 41.5 | 500.0 | 992.0 | 12 | 4.57 | 1.22 | 16.50 | 60.0 |

The growout period can be subdivided into several stages of growth to maximize tank space and biofiltration utilization. In most cases, four production stages for fry/nursery, juvenile, fingerling and growout are used, all following a quarantine stage.

In this design example, it was assumed that 0.25-gram fry were produced on site or brought in from an outside source, placed in a quarantine facility for six weeks and grown to 3.30 cm. At 3.91 cm/month, 40 weeks were required to reach a final length of 41.5 cm or 500 grams.

The production stages consisted of a four-week fry/nursery stage from 1.2 to 5.4 grams; a 12-week juvenile stage from 5.4 to 55.0 grams, a 12-week fingerling stage from 55.0 to 202.0 grams and a final 12-week grow-out stage from 202.0 to 500.0 grams. Setting a consistent period for the last three stages allowed a weekly market harvest and movement of fish from earlier stages into their succeeding tank stages. Thus, for continuous production, a maximum of 12 individual production pods were required, each with three stages.

Treatment system

Once the production plan and individual system tank sizes were determined, the individual culture system unit processes could be finalized. These would include the final tank layout, solids capture, biological filtration, aeration/degassing, circulation and waste management options. These identified design elements were then integrated into a complete design for the commercial production facility.

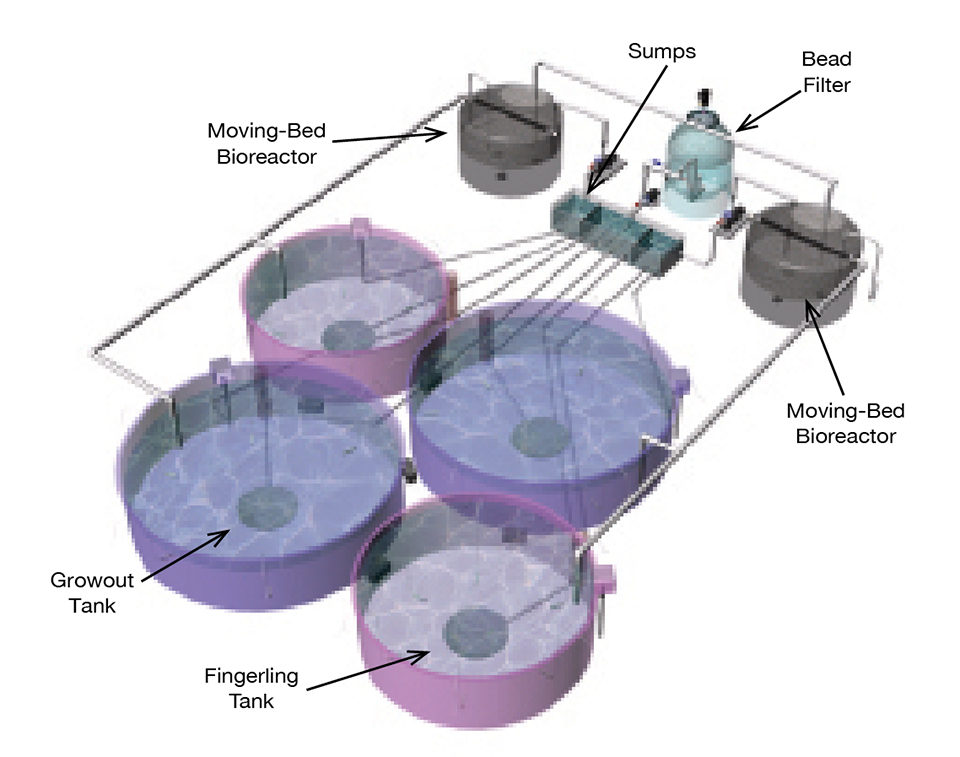

There were many engineering design solutions for the life support system and individual treatment options. Table 2 is a summary of one possible life support design that combined two juvenile and two growout tanks on a single system with a propeller-washed bead filter for solids capture and a moving-bed bioreactor for biofiltration. The entire production facility could easily occupy a single 1,400-cubic-meter commercial building.

Ebelling, Life support system design, Table 1

| Round tanks | Two fingerling – 3.6-m diameter, 1.2 m deep Two growout – 4.6-m diameter, 1.2 m deep |

| Circulation | 1,780 lpm: 340 lpm fingerling, 550 lpm growout 20% center drain, 80% sidewall discharge |

| Biofiltration | Two bioreactors – 3.9 m3 of media |

(Editor’s Note: This article was originally published in the March/April 2009 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

James M. Ebeling, Ph.D.

Aquaculture Systems Technologies, LLC

108 Industrial Avenue

New Orleans, Louisiana 70121 USA -

Douglas G. Drennan II

Aquaculture Systems Technologies, LLC

108 Industrial Avenue

New Orleans, Louisiana 70121 USA -

Dr. Michael B. Timmons, P.E.

Biological and Environmental

Engineering Department

Cornell University

Ithaca, New York, USA

Related Posts

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.

Innovation & Investment

A review of unit processes in RAS systems

Since un-ionized ammonia-nitrogen and nitrite-nitrogen are toxic to most finfish, controlling their concentrations in culture tanks is a primary objective in the design of recirculating aquaculture systems.