Comparison of inundated and semi-dry ongrowing methods

Bullfrog farming has developed rapidly during the last 30 years, from the extensive, single-crop, low-yield methods employed in the 1960s, to intensive, more scientifically based, multiple-crop systems that are more technically feasible and economically viable.

There are currently as many designs of bullfrog (Rana catesbeiana) culture facilities as there are commercial farms around the world. However, the management strategies employed, especially in reproduction, hatchery, and metamorphosis, follow common principles to maintain adequate water quality, nutrition, and appropriate culture densities.

During the ongrowing stage of the culture, there are two distinct types of culture systems: the “semi-dry” and the “wet” or “inundated” systems.

Semi-dry systems

Semi-dry systems are used by most of the bullfrog ongrowing facilities in Brazil. These include the aquaterrarium or multi-tank system, tank-island system, confinement rooms, and the amphifarm system. Only the last two systems are still in commercial use.

Confinement rooms

The use of confinement rooms represented a breakthrough in frog farming in the 1970s. The design and dimensions of the fattening area allowed for subsequent stocking of small lots of animals, resulting in year-round crops.

Confinement rooms are a series of small (12 to 15 square meters), square, all-concrete pens. Two-meter-high cinderblock walls enclose a cement ramp (5 to 7 percent slope), so that approximately half of the floor surface area is covered with water and the other half is dry. Frogs moisten their skin in the puddle formed at the deepest part of the ramp, and come out to feed on the dry area.

Each pen has an independent water inlet and drain pipe. A series of zinc or asbestos sheets cover the dry area of the pen so that the feed, which is provided either directly on the floor or in plastic troughs, is protected from the rain. This type of ongrowing area for frogs became very popular in Brazil and other countries in Latin America, such as Panama and Ecuador.

Amphifarm system

The amphifarm system facilitated better temperature control within the culture area. Amphifarm systems are employed in southern Brazil, and have been modified and adapted in Uruguay and Mexico.

Amphifarms consist of fattening pens of two types: initial and terminal. The features of both are basically the same, although the former, designed to hold newly metamorphosed froglets until they reach 40 grams, are smaller than those of the terminal fattening areas, where juvenile frogs are reared from 40 grams to market size of greater than 140 grams.

Both types of pens have the following features: two shallow canals (5 cm deep for initial, 10 cm for terminal areas) that run parallel along the longitudinal axis of the pen; a series of wooden planks, bricks or, as recommended by the original design, prefabricated concrete frog shelters placed parallel to the water channels; and a series of builtin or removable feeding troughs, facing the entrance to the shelters.

Fattening areas consist of arrays of 10 to 12 pens. They have walls made of cinderblock and chicken wire or shade cloth, with removable curtains. Buildings have asbestos or zinc roofing.

Wet or inundated systems

These systems were first employed in Asia, mostly in Taiwan and Thailand, and later adapted in Latin America in Argentina, Uruguay, Ecuador, Guatemala, and Mexico.

In general, wet-type frog farms are simple in design, consisting of a series of rectangular or square culture pens that range in size from 6 to 25 square meters. Asian farms use outdoor pens, which are covered with shade cloth to protect the frogs from avian predators, while Latin American farms have indoor culture areas, in tarpaulin- or plastic-covered buildings. With the exception of some Thai farms, whose pens have a distinct central platform covering approximately 30 percent of the total culture area, all other pens have a flat or sloped floor.

Pens are made of a wide variety of materials, such as plastic-lined wooden frames or plastic-lined cinderblock. Culture pens of the wet type, as opposed to those in semidry systems, can be employed for either of the frog culture phases (i.e., tadpole rearing nursery or ongrowing). Each pen has its own water inlet and drainpipe, and a constant flow of water is kept throughout the culture period.

Comparative management characteristics of semi-dry and wet systems

Table 1 presents the main management characteristics employed in both the semi-dry and the wet frog fattening systems. The wet system has some clear comparative advantages over the semi-dry system, as follows: a) better water quality because a constant water flow is provided to flush out excretion metabolites; b) less unconsumed feed, because the pellets float and thus remain longer in the water for frogs to consume; c) no need for live food, which increases the risk of pathogen introduction; and d) higher stocking rates. All of the above reduce the need for cleaning, which in turn minimizes stress on the cultured frogs.

Nava, Main operational and productive characteristics of the wet and the semi-dry frog ongrowing systems, Table 1

| Characteristic/Parameter | Semi-Dry System | Wet System |

|---|---|---|

| Wet surface area of floor | 30-50% | 100% |

| Water dynamics | Stagnant | Flow-through |

| Maximum stocking density | 20-50/m2 | > 100/m2 |

| Feed type | 80-95% pelleted: 5-20% fly larvae | 100% floating extruded pellet |

| Yield (kg/m2/crop) | 4-6 | 10-15 |

| Crops per year | 1.5 | 1.5 |

| Versatility (i.e., as hatching or tadpole rearing tanks) | No | Highly versatile |

| Nursery Stage | No | Yes |

Comparative production in wet and semi-dry systems

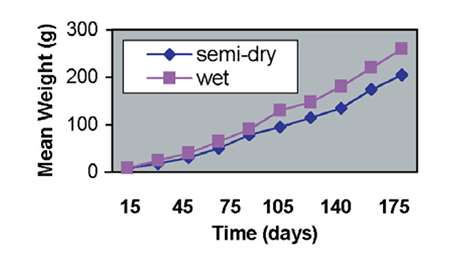

Other key factors being equal (i.e., nutrition and stocking density), the growth of bullfrogs is directly related to temperature. Therefore, in tropical areas where mean temperatures are above 27 degrees-C, frogs would grow to market size within five months from the froglet stage, regardless of the system. However, under the same factors, frogs reared in wet ongrowing pens grow 20 to 25 percent faster and larger than those reared in semi-dry systems. This results in a proportionally higher return in the wet systems, even considering the extra energy needed for water movement.

Conclusion

The wet or inundated system has many advantages over the semi-dry frog fattening system, but this flow-through system is only recommended for tropical or semi-tropical areas, because artificial heating would be required elsewhere. In the semi-dry systems, water remains static, and it is easier to increase water temperature through physical means (i.e. greenhouse effect).

Note: References available upon request to the author.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Alejandro Flores-Nava, Ph.D.

Centro de Investigación y de Estudios Avanzados-IPN

AP 73-CORDEMEX

Mérida, Yucatán, México 97310[120,109,46,116,121,99,97,110,111,99,46,114,101,109,97,101,105,99,46,110,105,107,64,115,101,114,111,108,102,97]

Tagged With

Related Posts

Intelligence

A motive, and a market, for farmed fish in Mexico

Boasting ample areas for aquaculture and a robust domestic demand for seafood – not to mention its close proximity to the U.S. market – a land of opportunity lies in Mexico. Fish farming is primed to meet its potential south of the border.

Intelligence

A review of European marine finfish hatcheries

As European aquaculture continues to diversify in the marine fish sector, technology advances and methodology in marine finfish hatcheries are proving vital.

Health & Welfare

Metabolomics approaches to improve mussel larval production

Variability in the quantity and quality of larval yields limit aquaculture growth. New biotechnological advances promise to revolutionize the way we assess and solve bottlenecks. A study demonstrated the use of metabolomics to assess and classify mollusk larvae quality and identify biochemical pathways that may reveal further important insights.

Health & Welfare

PUFAs affect growth, pigmentation in Senegal sole larvae

Inadequate levels of omega-3s in Senegal sole larvae diets can result in retarded growth, delayed metamorphosis, pigmentation problems and high mortalities.