Avoid installing cages where water quality problems are likely

Water quality in cage culture depends largely on the basic physical, chemical and biological characteristics of the water body and the particular site where cages are installed. Feed is applied for fish in cages, and uneaten feed and fish feces fall through the cage netting. Fish remove dissolved oxygen from water in cages for respiration and excrete carbon dioxide, ammonia and other soluble wastes back into this water.

Dissolved oxygen is replenished and soluble wastes are expelled by water flowing through cages. Thus, cages should be placed in areas where water quality is good and water velocity is adequate to flush cages rapidly. Moreover, the size, shape, construction and position of cages should be selected to favor rapid flushing of these culture units.

Flushing efficiency

Water passes primarily through the sides of cages. The ratio of the lateral surface area of a cage relative to its volume (LSA:V) is a good index of relative flushing efficiency (Table 1). Small square or circular cages have a potential 100 percent flushing efficiency. By comparison, a 4- × 4- × 4-meter square cage and a 4-meter-diameter, 4-meter-deep circular cage both have a potential flushing efficiency of 25 percent. As the sizes of circular or rectangular cages increase, flushing efficiency declines further.

Boyd, Lateral surface area:volume (LSA:V) ratios, Table 1

| Shape | Dimensions (m) | Lateral Surface Area (m2) | Volume (m2) | LSA:V Ratio | Potential Water Exchange (%) |

|---|

Shape | Dimensions (m) | Lateral Surface Area (m2) | Volume (m2) | LSA:V Ratio | Potential Water Exchange (%) |

|---|---|---|---|---|---|

| Square | 1 × 1 × 1 | 4 | 1 | 4 | 100 |

| Square | 2 × 2 × 2 | 16 | 8 | 2 | 50 |

| Square | 4 × 4 × 4 | 64 | 64 | 1 | 25 |

| Rectangle | 2 × 1 × 1 | 6.0 | 2.0 | 3.0 | 75.0 |

| Rectangle | 4 × 2 × 2 | 24.0 | 16.0 | 1.5 | 37.5 |

| Rectangle | 8 × 4 × 4 | 96.0 | 96.0 | 1.0 | 25.0 |

| Circle | 1 × 1 | 3.14 | 0.78 | 4.00 | 100.00 |

| Circle | 2 × 2 | 12.57 | 6.28 | 2.00 | 50.00 |

| Circle | 4 × 4 | 50.30 | 50.30 | 1.00 | 25.00 |

| Circle | 16 × 3 | 150.80 | 603.20 | 0.25 | 6.25 |

Dissolved oxygen can be replenished and wastes flushed out faster in small cages because small cages have a higher LSA:V ratio. Other factors being equal, fish can be cultured at greater density in small cages than in larger ones. Typical maximum fish densities in large cages over 30 m3 in volume are 2-30 kg per cubic meter, while it is not uncommon to rear fish at densities of 150-250 kg per cubic meter in small cages. The adjectives low-density, high-volume and high-density, low-volume are used to refer to these two types of cages, respectively.

Because of their higher flushing rates, small cages are more appropriate for sites with weak water currents or marginal water quality. At some sites, it may be advisable to use both small cages and lower biomass in order to avoid water quality problems.

Netting space, biofouling

The amount of open space in netting also affects the exchange of water in cages. The openings should be as large as possible without allowing fish to escape while still retaining sufficient netting strength to resist tearing. The open space is not determined entirely by mesh size; it also is influenced by the thickness of the material used to make the netting. For example, a 13-mm mesh nylon net has 87 percent open space, while a rigid, plastic net of the same mesh size has only 72 percent open space. The strength of nylon netting allows small strands to be used to form the mesh.

Biofouling reduces the amount of open space in netting and leads to less water exchange. Fine-mesh netting is more susceptible to biofouling than coarser netting, but flushing rates tend to decline over time for both types. Netting can be treated with biocidal compounds to reduce fouling, but this practice is discouraged for environmental reasons.

At many locations, cages must be periodically removed to clean the netting. When this is done, the waste water from cleaning should be discharged into a municipal sewer or held in a basin for sedimentation before being discharged back into natural water bodies.

Cage installation

Cage orientation should maximize exposure to the current. Cages should be oriented so that the aspect with the greatest surface area is perpendicular to the direction of the prevailing current. A circular cage has the advantage of always presenting the same amount of surface area regardless of how it is positioned with respect to the current. A square cage exposes the greatest surface area when its diagonal is perpendicular to the current, and the long side of a rectangular cage provides the greatest surface exposure.

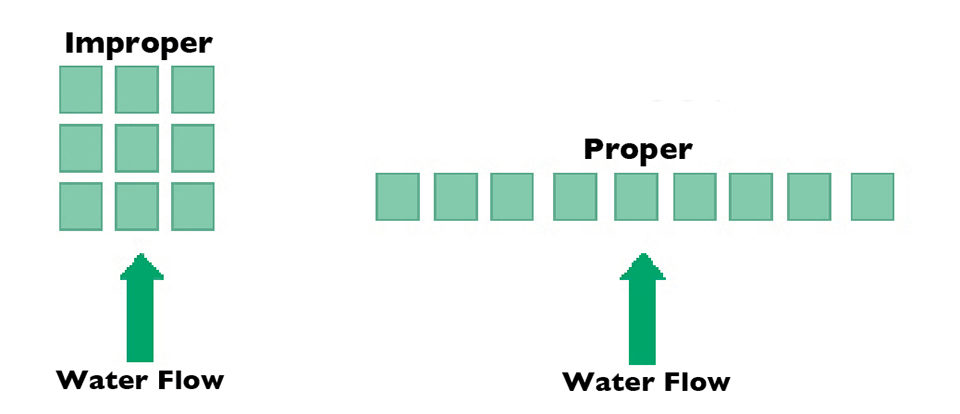

Several cages are usually installed at a farm. Cages should not be installed in clusters because the water passing through one cage enters the next before wastes are diluted and dissolved-oxygen concentrations increase by mixing with the greater water mass. Cages should be placed in lines, and if several lines are necessary, they should be separated by enough distance to assure that cage effluent is adequately diluted and does not negatively impact the influent of the next line of cages.

Water, bottom quality

Water quality should be monitored within cages to ascertain if flushing is adequate to maintain suitable conditions for fish growth. The ideal situation is for concentrations of key variables such as dissolved oxygen, pH, carbon dioxide, total suspended solids and total ammonia nitrogen to be the same inside cages as up current from cages.

If this cannot be achieved, concentrations of water quality variables should be within the following ranges to avoid stress on warmwater species: pH, 6.5 to 8.5; dissolved oxygen, greater than 5 mg/L; carbon dioxide, less than 5 mg/L; total ammonia nitrogen, less than 1 mg/L. Coldwater species require better water quality than warmwater ones.

Solid wastes settle from flowing water and accumulate on the bottom slightly down current from cage sites. Decomposition of organic wastes in sediment usually does not impact water quality within cages, but to avoid environmental degradation in sediment where solid wastes accumulate, cages should occasionally be fallowed or moved to other sites to allow benthic communities to recover.

Perspectives

Attention to good principles of cage design and placement is of little benefit when water quality deteriorates in the water body containing the cages. The greatest concerns are sudden thermal destratification, massive phytoplankton die-offs or extended cloudy weather – all of which can lead to low dissolved-oxygen concentrations in a water body.

These problems usually occur in water bodies that are highly eutrophic from inputs of nutrients from pollution – including too much cage culture. When such events occur, the only recourse is to apply mechanical aeration in cages, and few facilities have the capacity to do this.

It is important to avoid installing cages where water quality problems are likely, but it also is helpful to take advantage of cage design features and installation techniques that enhance water quality in cages.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Claude E. Boyd, Ph.D.

Department of Fisheries

and Allied Aquacultures

Auburn University

Auburn, Alabama 36849 USA

Tagged With

Related Posts

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.

Responsibility

Accuracy of custom water analyses varies

The reliability of trace element analyses reported by custom laboratories cannot be checked by simple techniques, and results may not always be accurate. One should check the reliability of major ion analyses by determining the charge balance and comparing the measured total ion concentration with the total ion concentration estimated from conductivity.

Health & Welfare

Acclimating shrimp postlarvae before pond stocking

Shrimp postlarvae acclimation before stocking into the various growout systems (ponds, raceways, tanks) is a critical – and often overlooked, sometimes taken for granted – step in the shrimp culture process. Various water quality parameters should be changed slowly so that the young shrimp have the time to gradually adapt to the new conditions.

Innovation & Investment

Acoustic control improves feeding productivity at shrimp farms

In systems recently developed for shrimp farms, passive acoustic-based technology enables sensor-based control of multiple automatic feeders. Improved growth and feed conversion have been recorded at commercial farms using the technology.