Low protein feeds and feeding strategies

In 1999, Belize Aquaculture Ltd. (BAL) utilized zero-water-exchange technology to produce 205,000 kg of shrimp from 15.2 hectares of pond area. This production rate of 13,350 kilograms per hectare represented a 30 percent improvement over 1998 results, due partly to refinement in feeds and feeding strategies. Feed protein levels were reduced from an average of 31 percent in 1998 to 24 percent in 1999. At the same time, FCR decreased from 2.2 to 2.0, and shrimp body retention of feed nitrogen increased from 23 percent to 37 percent. This article, the fourth in a series about BAL, describes the rationale for use of low protein feeds in zero exchange ponds, the formulations and feeding procedures used, and the impact of these feeds on shrimp performance, effluent quality, and operating cost.

Shift to bacterial community

In high-density, zero-water-exchange systems (with yields > 11,000 kilograms per hectare), the pond ecology shifts during the grow-out cycle from an autotrophic, phytoplankton-based microbial community to a heterotrophic, bacterial-based community. This shift accomplishes two important objectives. First, it improves water quality by rapidly digesting organic waste without production of toxic metabolites. For example, feeding rates at BAL have exceeded 350 kilograms per hectare per day without resulting in deterioration of water quality once the heterotrophic bacterial community has been established in the culture system. Second, it recycles wastes into nutritious bacterial flocs, which are the basis for “natural production” in this system.

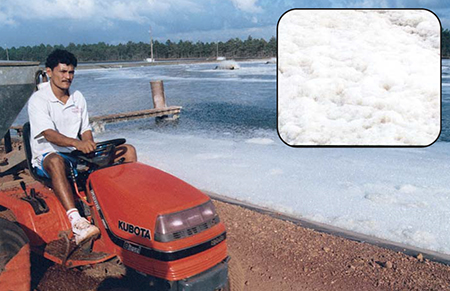

In the BAL system, the shift from phytoplankton to bacteria normally occurs around week 9 to 10 of the culture cycle. At that point, surface foam disappears and green phytoplankton blooms are replaced by bacterial flocs, which turn the water a brownish to blackish color. Bacteria counts increase from about 105 bacteria per milliliter in the first eight weeks to over 109 heterotrophic bacteria by the end of the cycle. When bacteria dominate the pond, few phytoplankton cells can be found, and, when present, these cells are generally phytoflagellates.

Description of flocs

Initially, bacterial flocs are small, but by the end of the culture cycle, they can be greater than 200 microns in diameter. These aggregates of bacteria living in a matrix of layered silica and calcium comprise an important part of the natural diet of L. vannamei. Typically, the flocs will consist of 45 percent protein, which is nearly double the protein level of feeds going into the pond. The amino acid profile of flocs is typical of bacteria (Table 1) (Rod McNeil, personal communication). Methionine would appear to be the limiting amino acid. Undoubtedly, the floc also provides significant levels of vitamins, minerals and possibly exogenous enzymes that aid in digestion.

McIntosh, Nutritional composition (% DM basis) of detrital material, Table 1

| Pond 12 | Pond 22 | Mean |

|---|

Pond 12 | Pond 22 | Mean | |

|---|---|---|---|

| Organic Matter | 78 | 66 | 72 |

| Ash | 21 | 32 | 26.5 |

| Protein | 51 | 35 | 43 |

| Fat | 10 | 15 | 12.5 |

| Arginine | 2.3 | 1.61 | 1.95 |

| Lysine | 2.5 | 1.7 | 2.1 |

| Methionine | 0.61 | 0.35 | 0.48 |

2 Pond fed with 31.5% protein diet

3 Pond fed with 22.5% protein diet

Table 1. Nutritional composition (% DM basis) of detrital material collected from ponds receiving feeds with varied protein content.

Maintaining bacterial flocs

The concept of maintaining a healthy heterotrophic community in a pond is quite similar to managing the bacterial community in a compost pile for gardening waste. The following criteria must be met:

- Maintain an aerobic state

- Continually mix

- Supply with constant input of organic material with a balanced organic carbon to nitrogen ratio (C:N).

C:N ratios

As with composting, materials that are high in carbon and low in nitrogen, such as leaves (C:N of 50:1), do not decompose quickly by themselves. Neither do materials which are low in carbon and high in nitrogen, such as manure from laying hens (C:N of 6:1). However, a mixture of these ingredients decomposes quickly, because bacteria operate most efficiently at a C:N ratio of about 30:1.

Aquaculture diets with protein levels of 35 to 40 percent have C:N ratios of less than 10:1. Feeding such diets in highdensity, zero-water-exchange systems slows the rate of waste decomposition and results in an accumulation of inorganic nitrogen (ammonia, nitrite and nitrate) in the pond. Thus, low protein diets have a more balanced C:N ratio for bacterial decomposition than typical intensive shrimp diets with a protein level of 35 to 40 percent.

It is intriguing that L. vannamei are able to grow rapidly on low protein diets when several laboratory studies have indicated that their optimal protein requirement is 30 to 35 percent. The explanation seems to lie in the culture system. Most of the laboratory studies were conducted in clean tanks without nutrient contributions from either plankton or bacterial communities. In zero-exchange systems with an active microbial community, nitrogen from unconsumed feed, fecal waste, and ammonia is converted into bacterial protein that can be consumed at a later time by the shrimp. A number of laboratory studies have confirmed this effect. For example, research by Mario Velasco at Texas A&M University demonstrated that growth of L. vannamei in static-water tanks was not significantly different when offered a range of protein levels from 18 to 33 percent.

BAL diets

To efficiently manage the nutrition of the microbial and shrimp populations during the course of the production cycle at BAL, two different types of low protein pellets are utilized:

- Grain-based pellet

- Shrimp feed pellet

Grain-based pellets

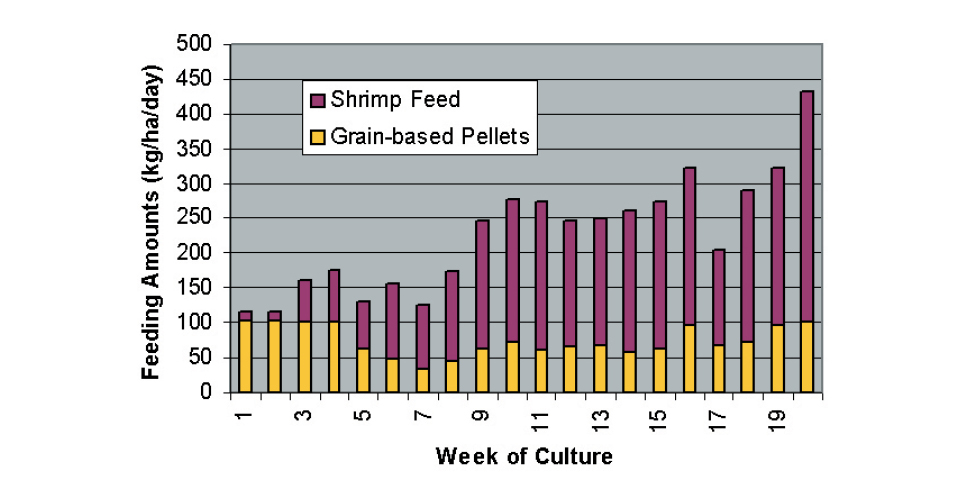

Grain-based pellets consist of a mixture of ground wheat, corn, and soy with a protein level of 18.5 percent. Initial application rate is approximately 100 kilograms per hectare per day (Fig. 1). This provides an inexpensive organic substrate with proteins and carbohydrates similar to shrimp diets and a moderate C:N ratio. Having a similar biochemical characteristic to shrimp feeds and a moderate C:N ratio helps stimulate the growth of heterotrophic bacteria specific to breaking down and recycling shrimp feed and associated wastes.

Shrimp feed formulation

During the past two years, BAL has experimented with feed protein levels that ranged from 21 to 35 percent. All diets have been formulated using only high quality, highly digestible ingredients. Regardless of the protein level, all feeds have contained the same levels of lipids, vitamins and minerals. Lipids have been primarily fish oils, and minerals have been added in a highly digestible form. For example, phosphorous has been added in the form of monosodium phosphate.

In selecting ingredients that contribute protein to the diet, two factors are considered: amino acid composition and digestibility. Generally, the most balanced and digestible proteins are found in high protein ingredients. For this reason, our diets typically contain a mix of high-protein ingredients and high-carbohydrate ingredients. The high-protein ingredients are formulated to meet amino acid requirements for shrimp. Three amino acids are considered critical in balancing formulas for our feeds: methionine, lysine and arginine. As protein levels in the feeds are reduced, it has become more difficult to meet metabolic requirements for arginine and methionine with commonly available ingredients. A typical analysis from the feeds and grain-based pellets used at BAL are shown in Table 2.

McIntosh, Typical feed analysis of diets and grain-based mix, Table 2

| Diet | 32% Protein | 25% Protein | Grain-Based Pellets |

|---|

Diet | 32% Protein | 25% Protein | Grain-Based Pellets |

|---|---|---|---|

| Protein (%) | 31.5 | 24.5 | 18.5 |

| Lipid (%) | 9.0 | 9.0 | 3.0 |

| Ash (%) | 7.5 | 6.0 | |

| Phosphorus (%) | 0.9 | 0.8 | |

| Calcium (%) | 1.0 | 0.9 | |

| Arginine (%) | 1.55 | 1.40 | 1.2 |

| Lysine (%) | 1.55 | 1.45 | 1.0 |

| Methionine (%) | 0.65 | 0.62 | 0.3 |

| Approx. C:N | 11:1 | 14:1 | 20:1 |

Use of fishmeal

Fishmeal is currently considered essential for shrimp feeds, since it provides a highly digestible source of essential amino acids, omega 3 fatty acids, phospholipids, cholesterol, attractants and minerals. However, it is derived from a limited resource. Therefore, one of the goals of the diet development work at BAL has been to reduce the amount of fishmeal in the diet. Fishmeal use has been reduced from the 18 to 20 percent inclusion levels used in 1998 to 12 to 14 percent inclusion levels in 1999. When the all-vegetable protein grain-based pellets are included in the feeding equation, fishmeal content for the feed program at BAL is less than 9 percent. Assuming an average fishmeal inclusion rate of 9 percent, then for each kilogram of menhaden that is converted to fishmeal, BAL produces 1.7 kg of shrimp. Ponds that have been fed diets with less than 12 percent fishmeal (8 percent fishmeal overall) have yielded harvests of greater than 14,000 kilogram per hectare. One of the goals of BAL is to further investigate reductions in the use of fishmeal and animal protein in the diet.

We have observed that L. vannamei readily consume grain-based pellets, even though they contain no fishmeal or other marine meal. On the other hand, L. stylirostris does not directly consume the grain-based pellets. Thus, the use of low-fishmeal diets may be limited to shrimp species that are more herbivorous in their eating habits.

Effluents

BAL is continually striving to reduce the quantity of effluents released to the environment, especially the amount of nitrogen and phosphorus contained in this effluent. We have continued to experiment with diets containing less protein and phosphorus. Pond yields have actually increased as feed protein and phosphorous levels declined in the diet from an initial 35 percent and 2 percent to 23 percent and 0.9 percent protein and phosphorus, respectively. Concurrent with a decrease in feed protein levels, there has been an increase in the efficiency with which input nitrogen is retained by the shrimp carcass. This indirectly indicates that nitrogen is being recycled within the pond and passed several times through the shrimp gut. From an environmental perspective, less nitrogen is returned to the environment.

Phosphorus levels in the pond build up both as inorganic and organic forms. Since ponds are lined with high-density polyethylene, phosphorus is not absorbed by pond soils. This results in a continuous increase in the levels of soluble phosphorus during the grow-out cycle. With higher ambient levels of inorganic and bacterial-bound phosphorus in the water, it may be possible to further reduce the dietary levels of phosphorus from the current 0.9 percent.

BAL feeding program

As previously described, ponds receive two types of feeds; a grain-based pellet and a complete shrimp feed. Feeding is started at the time of pond preparation or 7 days prior to stocking a new pond with the addition of 10 kilogram per hectare per day of the grain-based pellet. After stocking ponds, the daily ration of feed approximates 30 percent of the daily ration that a pond would receive at the end of the cycle (Fig. 1). A higher portion of the grain-based pellets relative to shrimp feed is fed to newly stocked ponds. The amount of shrimp feed that is initially applied to the ponds is set according to a feed table. As the shrimp grow, the amount of shrimp diet is increased in accordance with consumption. At the end of a cycle, 80 percent of the daily ration is in the form of the shrimp diet, while only 20 percent is comprised of grain-based pellets. In a typical grow-out cycle, shrimp feed will generally represent 60 to 65 percent of the total inputted material, with the grain-based pellet representing the balance.

Ponds are fed from two times (early cycle) to five times (late cycle) per day. Feeding starts at 6:30 a.m. and ends at 9:30 p.m. Grain-based pellets are distributed at the 10:00 a.m. and 1:30 p.m. feedings. Shrimp feed is distributed in the early morning and evening. A blower distributes all feed from the pond berms. Feed consumption is monitored by feed indicator trays, starting during the fifth week of culture, or at the time shrimp reach two grams. There are a total of six indicator trays in each 1.6 ha pond. Each tray receives a cup of feed or grain-based pellets; and after two hours the tray is visually checked. If the tray is empty for three consecutive days, then the rate will be increased. On the other hand, if over 25 percent of the feed initially put on the tray remains, the feed rate will be immediately decreased.

Diet performance

Diet protein levels from 22 to 35 percent have not significantly affected growth, survival, or FCR over a complete grow out cycle (Table 3). However, growth rates of small shrimp (less than 4 g) have been approximately 30 percent higher when fed diets with protein levels over 30 percent (Table 4). After animals reach 3 to 4 grams, dietary protein levels from 21 to 30 percent have little effect on growth rate.

McIntosh, Comparison of pond performance of the Mexican strain of L. vannamei, Table 3

| Feed Protein Category | > 25% | < 25% |

|---|

Feed Protein Category | > 25% | < 25% |

|---|---|---|

| Average Feed Protein | 23.0 | 28.5 |

| Content (%) | ||

| Growth Rate (g/week) | 0.82 | 0.79 |

| Survival Rate (%) | 77 | 73 |

| FCR | 2.0 | 2.1 |

| Nitrogen Retention | 31 | 38 |

| Efficiency (%) |

McIntosh, Growth rates (g/week) of small and large L. vannamei, Table 4

| Size Class | 28.5% Protein Feed | 23.5% Protein Feed |

|---|

Size Class | 28.5% Protein Feed | 23.5% Protein Feed |

|---|---|---|

| < 4 g | 0.66 | 0.43 |

| 4-12 g | 0.97 | 1.00 |

The period in which there has been a growth response to protein level in the feeds represents the first seven to nine weeks of the cycle. It is unclear whether this difference is due to a higher metabolic requirement for protein of juvenile shrimp, or whether the pond has developed insufficient bacterial floc to offset the reduction in dietary protein.

Although bacterial protein is not of the highest quality, it provides a significant source of amino acids and energy for shrimp growth. In one short experiment, a pond with shrimp biomass exceeding 9000 kilograms per hectarea was taken off feed. Detritus alone supported a growth rate of 0.5 grams per week; which was 50 percent of the growth rate supported when the ponds were fed with a 25 percent protein shrimp feed. This suggests that the detrital floc does not completely replace the requirement for feed, but does contribute significant nutrients to the shrimp diet. We are continuing to evaluate the nutritive value of detritus and how this information can be used to make more effective, and complementary shrimp feeds.

Currently we feed a 31 percent protein diet for the first seven weeks of the grow-out cycle, thereafter switching to a 24 percent protein diet. The feeding program averages 23 percent protein for the complete grow-out cycle (all diets plus grainbased pellet).

Nitrogen retention efficiency1 has been positively affected by the reduction in dietary protein levels. For diets that averaged greater than 25 percent protein, the average nitrogen retention was 31 percent. Reducing the dietary protein level to less than 25 percent has increased average nitrogen retention to 38 percent. In a single pond that was fed an average of 20.2 percent dietary protein, nitrogen retention was 48 percent with a corresponding yield of 16,500 kilograms per hectare.

Postlarval nutrition

Optimal health of post larvae is essential to achieving consistent performance and yields. At BAL, all post larvae are acclimated for two days to pond conditions. During this period, the post larvae are “fattened” on enriched artemia and acclimation/immunostimulant diets rich in vitamins and omega-3 fatty acids and marine proteins. Experience has shown this protocol results in higher pond survival and initial growth rates.

Economics

The BAL feeding program using a combination of grain-based pellets and balanced shrimp diets has resulted in an average FCR of 2.0. The grain-based pellets account for 0.8 of the conversion, and the shrimp diet accounts for 1.2 (Fig. 1). If we assign a value of $0.26 U.S. per kilogram for the 18 percent protein grain-based pellets and $0.53 U.S. per kilogram for the 24 percent protein shrimp feed; the average cost of feed used in the production of a kilogram of shrimp is $0.85 U.S.

By comparison, typical high protein diets for intensive shrimp culture cost about $1.00 U.S. per kilogram. Assuming a typical feed conversion ratio of 1.7, this would amount to a feed cost of $1.70 U.S. per kilogram or double that of BAL. As we learn more about the nutritive value of the bacterial flocs, and how the flocs can be optimized in the culture system, feeding programs can be refined for further cost reductions.

Future direction

BAL continues to conduct diet trials with the goal of matching the quality of dietary inputs with the nutritional supplementation provided by bacterial flocs in our zero-exchange system. We feel that a nitrogen retention efficiency of 40 percent is an achievable mid-term goal. Also of interest is the addition of nutritional supplements to the diets that might enhance the effectiveness of lower protein feeds. Such supplements might include enzymes, immunostimulants, and assimilatable limiting essential amino acids. Our goal is to develop a feeding program that results in consistently high pond production using diets that complement the nutrition from natural components of the zero-exchange pond environment.

Nitrogen retention efficiency = shrimp carcass nitrogen / (nitrogen in fertilizers + grain based pellets + shrimp feed).

(Editor’s Note: This article was originally published in the April 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Robins P. McIntosh

Belize Aquaculture, Ltd.

#1 King Street, P.O. Box 37

Belize City, Belize Central America

Related Posts

Intelligence

Changing paradigms in shrimp farming, part 1

Conventional wisdom for farming white shrimp involves semi-intensive culture in large ponds, routine water exchange and reliance on wild broodstock.

Intelligence

Changing paradigms in shrimp farming, part 3

Square-shaped and deep ponds may explain partially why Belize Aquaculture is able to produce a large amount of shrimp on a unit area basis.

Intelligence

Changing paradigms in shrimp farming, part 5

A zero-water-exchange strategy to produce shrimp reduces the effluents and sediments that would normally be released to the environment by a typical intensive shrimp farm.

Intelligence

Changing paradigms in shrimp farming, part 6

The final factor in developing a heterotrophic system is the amount of organic material being fed to a pond, and the carbon per nitrogen balance of that material.