Establishment of heterotrophic bacterial communities

Belize Aquaculture, Ltd. uses a zero-water-exchange/recycle strategy to produce shrimp. This technology significantly reduces the effluents and sediments that would normally be released to the environment by a typical intensive shrimp farm, and markedly increases farm biosecurity. The system has sustained very high yields and improved feed and pond utilization efficiency.

Nutrients are not flushed from the ponds – as occurs when water is exchanged from conventional ponds – but are recycled within the pond, with a higher percentage of the nutrients assimilated into shrimp carcass biomass. When water exchange is used as the main pond management tool, the basic ecological communities are dominated by phytoplankton and zooplankton. This autotrophic community can be very unstable and result in wide swings in pH. It is also dependent on sunlight for its energetics, and does not result in efficient recycling of nutrients within the pond system.

Heterotrophic bacterial communities

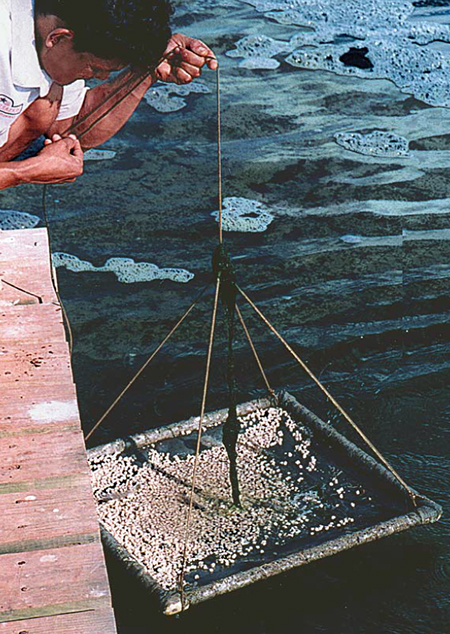

The goal of managing a pond with high shrimp stocking densities and no water exchange is to shift from an autotrophic ecological community of phytoplankton to that of a heterotrophic community of bacteria. The heterotrophic communities in Belize Aquaculture ponds that develop after seven to eight weeks are characterized by flocs composed of bacteria cells imbedded in a matrix of calcium and silicate.

Initially the flocs are small, but by the end of the cycle they can be as large as 2 mm. They add additional surface area to the pond, resulting in increased assimilation of dissolved organics and the recycling of inorganic nutrients. Flocs enable omnivorous shrimp species like L. vannamei to directly consume the bacterial biomass, which is high in protein, amino acids and certain microelements. Shrimp consumption of these flocs contributes to both the nutrition of the shrimp and efficient recycling of pond nutrients into shrimp biomass.

Overview: Belize aquaculture pond management

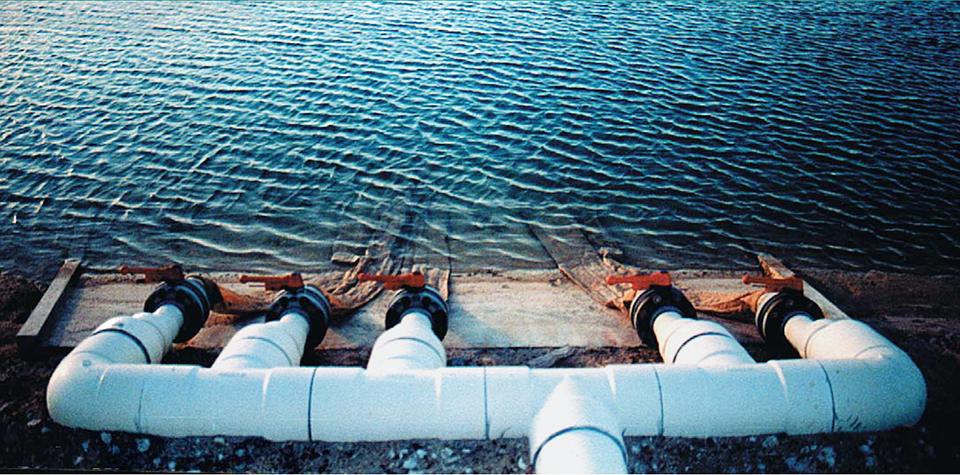

Water filtration

Ponds are initially filled with new seawater that has been filtered down to 165 μ. Using this size mesh has effectively eliminated fish, crabs, mussels, and most barnacles from our ponds. Newly filled ponds are fertilized with nitrogen and phosphorous fertilizers over a two-week period.

After developing a typical shrimp pond phytoplankton bloom with associated zooplankton, the pond is stocked with PL10 at densities that produce shrimp yields over 13,000 kilograms per hectare. It becomes more difficult to shift from an autotrophic ecology to a heterotrophic ecology if stocking rates are not high enough to produce a shrimp yield greater than 13,000 kilograms per hectare.

Feeding

Ponds receive both a grain-based pellet and a complete shrimp feed. After stocking a pond, the feed rate is set at 200 to 250 percent of shrimp biomass, an amount of feed or organic input much larger than the shrimp will consume. This extra feed nurtures bacterial populations that will be required later in the cycle to handle the large amount of wastes generated as the shrimp biomass increases.

A grain-based pellet (18 percent protein) with a carbon/nitrogen ratio of 20:1 represents 90 percent of the total feed added to the pond. A complete shrimp diet represents the balance of the feed input. Later in the cycle the grain-based diet is reduced to 25 percent of the total feed input.

Water quality

As heterotrophic conditions develop during the seventh or eighth week of culture, pH and alkalinity decreases and carbon dioxide increases. In order to maintain optimal conditions, alkalinity is maintained at levels between 75 and 90 ppm by the addition of hydrated lime.

Initially, oxygen levels show diurnal variations typical of semi-intensive culture ponds being managed with water exchange. As heterotrophic conditions develop, the variation between morning and afternoon levels becomes negligible.

Aeration

Aerator operation is variable. During daylight hours when shrimp biomass is less than 12,000 kilograms per hectare, 50 percent of the paddlewheels are turned on, while 100 percent of aerators are operated when shrimp biomass exceeds 12,000 kilograms per hectare and at night.

Water removed from ponds during drain harvest operations is directed via canals to a settling basin. Water is retained in the settling basin for seven days, a period of time sufficient to remove up to 70 percent of the nitrogen and 80 percent of the phosphorous. Nitrogen removal occurs both by the settling of organic-bound nitrogen and denitrification of inorganic forms of nitrogen. Phosphorous is removed either through the settling of organic forms or the absorption of inorganic forms into soil particles on the basin bottom.

Pond preparation

The day following a harvest, the pond is cleaned by washing any accumulated sludge into the settling basin. The pond is sun-dried for one day and then filled with water from a settling basin that has been treated for a seven-day period. This recycled water is treated with 300 kilograms per hectare hydrated lime, 250 kg silicate cake, and 300 kilograms per hectare of the grain-based pellet. The materials are added in three applications over a five-day period. The pond is then ready for stocking seven days after the pond was harvested.

Development of the heterotrophic system

Several factors are key to developing a heterotrophic system, including:

- high stocking rates that produce sufficiently high shrimp biomass

- adequate pond aeration to provide sufficient water movement to keep solids suspended and sustain oxygen levels to support a healthy shrimp population

- relatively high organic inputs to feed both shrimp and bacteria populations, and a correct balance of nutrients required by bacteria, such as carbon and nitrogen.

High stocking rates

When shrimp stocking rates fall below 100 PLs per square meter, it becomes more difficult to establish heterotrophic condition. Stocking at higher rates results in a system that seems to stabilize earlier, with cleaner pond bottom conditions. Culture conditions have been most stable with stocking rates between 125 and 140 PLs per square meter. At higher shrimp biomass, the animals’ activity stirs up the pond bottom, leading to more solids in suspension and resulting in cleaner conditions.

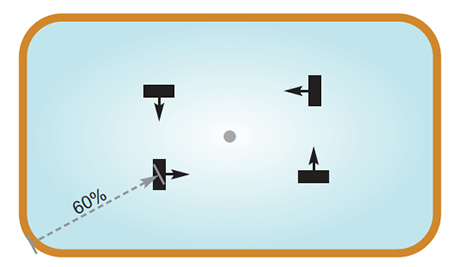

Water movement

Sufficient water movement to keep bacterial flocs in suspension is also critical. Large flocs will settle out very quickly when water movement is eliminated. Belize Aquaculture places paddlewheel aerators 60 percent of the distance from the corner of the ponds toward the center (Fig. 1.)

These aerators are directed to create a clockwise circular water motion. Water velocity varies from 0.23 meters per second at the outside of the pond to 0.05 meters per second at the middle of the pond. Oxygen levels remain above 4 ppm throughout the pond, except for an area around the pond center where the oxygen level drops to below 1 ppm.

It is in this center area (approximately 15 percent of the total pond area) that water velocity is reduced to a level where solids settle from the water column. To further minimize settling, two aspirator-type aerator devices direct a current of water at the bottom of the center area. Settled material in this area is then resuspended and moved back into the primary circular water current.

Aerator positioning

Positioning of the aerators has been very important in developing a system that results in maximizing the amount of material kept is suspension, while minimizing the accumulation of anaerobic sludge on pond bottoms. Belize Aquaculture has determined that – depending on salinity and temperature conditions – one applied horsepower of paddlewheel aeration is sufficient to provide sufficient oxygen transfer to support 450 to 550 kilograms per hectare of shrimp biomass in each pond.

(Editor’s Note: This article was originally published in the December 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Related Posts

Intelligence

Changing paradigms in shrimp farming, part 1

Conventional wisdom for farming white shrimp involves semi-intensive culture in large ponds, routine water exchange and reliance on wild broodstock.

Intelligence

Changing paradigms in shrimp farming, part 4

In high-density systems with zero water exchange, pond ecology shifts from an autotrophic, phytoplankton-based microbial community to a heterotrophic, bacterial-based community.

Intelligence

Changing paradigms in shrimp farming, part 3

Square-shaped and deep ponds may explain partially why Belize Aquaculture is able to produce a large amount of shrimp on a unit area basis.

Intelligence

Changing paradigms in shrimp farming, part 6

The final factor in developing a heterotrophic system is the amount of organic material being fed to a pond, and the carbon per nitrogen balance of that material.