Control methods reduce pathogen levels so acute disease losses are less likely to occur

Production approaches such as in-pond raceway systems (IPRS) and split ponds are providing an alternative to traditional pond culture for raising catfish in the southeastern United States. Currently, approximately 600 ha of commercial split ponds are in production in Mississippi, Arkansas and Alabama, and the area continues to increase each year. In addition, a small number of farmers in Alabama have been successfully implementing IPRS on their commercial catfish operations.

A significant advantage noted by farmers utilizing these systems is the reduced costs associated with the chemical treatment of diseases, which are notably lower than for traditional earthen ponds.

Diseases in IPRS

The Alabama Fish Farming Center in Greensboro, Alabama, and Auburn University have been tracking the incidence of disease in IPRS since 2008. The most common diseases observed include columnaris, enteric septicemia of catfish and problems caused by Aeromonas hydrophila bacteria. There have also been cases involving parasites such as trichodina, henneguya, ich and others.

Fish kills caused by disease outbreaks have varied in scope, ranging from a few dead fish to thousands, depending on the disease and severity of infection. While disease outbreaks are never desired, one advantage that IPRS have over traditional pond culture is they are much cheaper to treat with chemicals.

Disease prevention, control

A management approach that focuses on disease prevention and control is the key to a successful farming operation. Site selection, water source and fish supplies should be carefully considered. All fish stocked should be free of obligate pathogens. Nets, boots, buckets and other commonly used equipment should be sanitized on a regular basis, especially if they are used at another location.

Although a disease prevention program is important in controlling fish disease, it’s not a guarantee. Such programs are, however, worth the effort from an economical and production standpoint. Control methods reduce pathogen levels so acute disease losses are less likely to occur. Chemotherapeutics are most successful when environmental stressors are minimized and good health management practices are followed.

Chemical treatments

The application of chemical treatments in IPRS is based on temperature, water quality and parasite/bacteria findings from fish. Since chemical treatment cost is not a limiting factor in IPRS, as it is in traditional ponds, a more proactive approach to keeping fish healthy can be applied. In addition to formalin and hydrogen peroxide (approved for food fish treatment), potassium permanganate and copper sulfate have been used to treat pond water. All chemicals should first be diluted with water before application to avoid “hot spots” that could stress the fish.

In order to treat an individual raceway cell in an IPRS, a barrier is needed to keep the chemical treatment in the cell for the allotted amount of time. At Dean Wilson Farms in Browns, Alabama, USA, a plastic tarp approximately the width of the raceway cell is attached to a 6-meter-long PVC pipe of 5-cm diameter. The pipe rests on top of the cell wall, and a piece of reinforcing bar is used to reduce the buoyancy of the bottom side of the tarp. This allows the tarp to stretch across the entire open channel area.

Treatments are only administered during the day, when photosynthesis is greater than respiration. Water flow to the raceway cell is shut off, aeration is applied with a diffuser grid and regenerative blower, the chemical treatment is added to the cell, and fish are monitored continuously.

Measurements of dissolved-oxygen concentrations in the cells being treated are highly recommended. After the treatment, the tarp is removed, water flow is restarted, and aeration is reactivated in a very simple and inexpensive, yet efficient way to treat for diseases.

Proactive health management

The best example of a proactive health management approach in the IPRS is the periodic treatment of the water in the flow-through raceways with potassium permanganate to help reduce organic loads. There is evidence that repeated exposure of the aquaculture system to the compound enhances fish survival and feed conversion, especially under intensive farming conditions.

A minimum of five days between treatments is recommended. In intensive systems such as IPRS, a 5-ppm application rate is recommended for 30 minutes to an hour. In traditional ponds, applications of 2 to 4 ppm based on the organic load are recommended. A treatment rate of 3 to 4 ppm is demonstrated in Table 1 for a traditional pond system compared to an IPRS cell. This type of treatment also serves as a preventive and/or control measure against waterborne protozoa such as Ichthyobodo, monogenetic trematodes, and bacterial infections.

Bott, Cost comparison of one chemical treatment, Table 1

| Chemical | Chemical Cost (U.S. $) | Raceway Cells (43.6 m3) Quantity/Treatment Concentration | Raceway Cells (43.6 mm3) Total Cost 1 Cell | Raceway Cells (43.6 mm3) Total Cost 5 Cells | Traditional Pond (2.3 ha, 1.67 m depth) Quantity/Treatment Concentration | Traditional Pond (2.3 ha, 1.67 m depth) Total Cost 1 ha | Traditional Pond (2.3 ha, 1.67 m depth) Total Cost 2.3 ha |

|---|

Chemical | Chemical Cost (U.S. $) | Raceway Cells (43.6 m3) Quantity/Treatment Concentration | Raceway Cells (43.6 mm3) Total Cost 1 Cell | Raceway Cells (43.6 mm3) Total Cost 5 Cells | Traditional Pond (2.3 ha, 1.67 m depth) Quantity/Treatment Concentration | Traditional Pond (2.3 ha, 1.67 m depth) Total Cost 1 ha | Traditional Pond (2.3 ha, 1.67 m depth) Total Cost 2.3 ha |

|---|---|---|---|---|---|---|---|

| Formalin | $1.92/L | 6.54 L (150 ppm) | $12.56 | $62.78 | 333.6 L (20 ppm) | $640.51 | $1,473.18 |

| Potassium permanganate | $7.60/kg | 0.22 kg (5 ppm) | $1.67 | $8.36 | 49.8 kg (3 ppm) 66.5 kg (4 ppm) | $378.48 | $870.50 |

Research has shown that high concentrations of potassium permanganate can be added to ponds with heavy plankton blooms without danger to fish. A simple bioassay can be performed to determine the correct concentration of potassium permanganate required, although most culturists make repeated applications until a pink hue persists in the pond water.

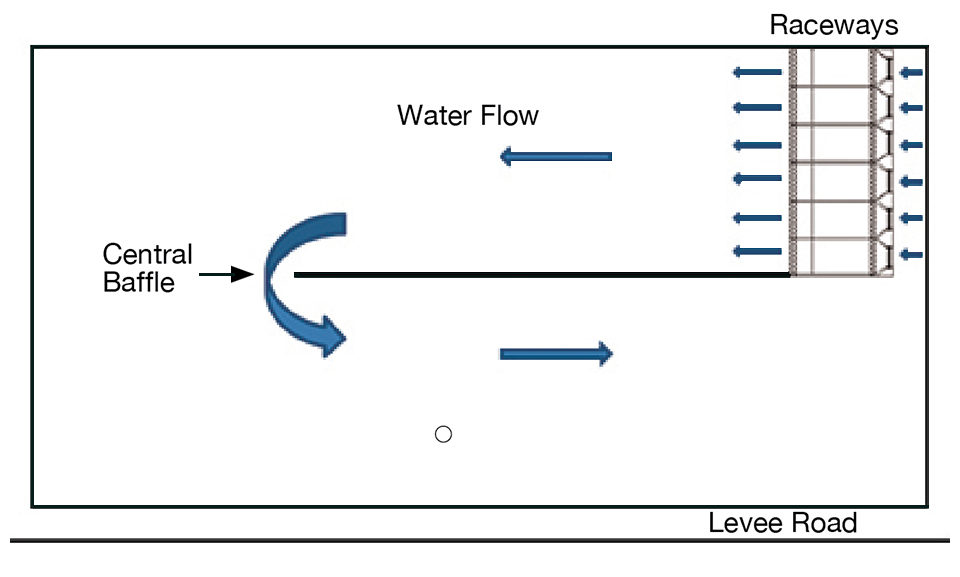

Culturists are seldom concerned with high application rates of chemicals and associated mortality of plankton dissolved-oxygen depletion in the IPRS since the treated water volume is usually less than 5 percent of the total pond water volume (Fig. 1). Some farmers have used average Secchi disk visibility measurements to estimate the abundance of plankton or organic matter concentration, which has aided in making decisions regarding treatment concentrations (Table 2).

Bott, Preventative measure schedule for treatment of water, Table 2

| Water Temperature (° C) | Average Secchi Disk Visibility (cm) | Concentration (mg/L) | Time (minutes) |

|---|

Water Temperature (° C) | Average Secchi Disk Visibility (cm) | Concentration (mg/L) | Time (minutes) |

|---|---|---|---|

| 15 | 30.2 | 2 | 45 |

| 17 | 22.8 | 4 | 45 |

| 19 | 24.5 | 3 | 30 |

| 21 | 19.0 | 5 | 30 |

| 23 | 22.5 | 5 | 30 |

| 25 | 25.1 | 5 | 30 |

| 27 | 25.6 | 4 | 30 |

| 29 | 25.5 | 4 | 20 |

| 31 | 20.9 | 5 | 15 |

| 33 | 16.3 | 6 | 15 |

Formalin as parasiticide

Formalin, a parasiticide approved for use with catfish, is another proactive treatment in IPRS. The recommended application rate in raceways is 150 ppm for 30 minutes. An indefinite treatment rate of 15 to 25 ppm is recommended for ponds. During periods of high water temperatures, critical oxygen depletions can occur days after treatment. Therefore, both IPRS and ponds should have sufficient aeration to support the biomass of the systems.

The total cost for a formalin treatment at 150 ppm in a five-cell raceway for a 2.3-ha pond is U.S. $62.78. In contrast, treating a 2.3-ha pond of 1.67-m average depth at 20 ppm with formalin would cost $1,473.00 or $641.00/ha. Similarly, the cost of treatment with potassium permanganate is much lower in an IPRS compared to a traditional earthen pond.

The total cost for the five-cell raceway system using potassium permanganate at 5 ppm would be $8.36/treatment, while for a 2.3-ha pond, similar treatment at 3 and 4 ppm would cost $871.00 to $1,162.00, respectively (Table 1). The cost of chemical treatment in an IPRS system is also lower than treating a split pond production system, since split ponds have a larger fish culture area, approximately 20 percent of the total pond area.

It is also worth noting that since raceways can be flushed at the end of treatment, it is possible to use a much higher treatment concentration than in traditional earthen ponds, as presented in the formalin treatment example. Presently formalin is not routinely used in pond settings, as it is cost prohibitive, so the IPRS approach opens up more affordable chemical treatments.

Tracking treatment

In addition to the lower cost of treating the water in IPRS compared to traditional ponds, it is easier to monitor and track mortalities in an IPRS. Inventory control is a vital component of modern livestock production that is missing in some commercial pond aquaculture systems.

Farmers have also noted that due to the increased feeding efficiency and smaller culture area in these systems, it is much easier to verify the delivery and response of fish to antibiotic feed in an IPRS. There are also considerably less time and labor – and hence lower costs – involved to treat raceways versus whole ponds.

Perspectives

The IPRS in Browns, Ala., has demonstrated production capabilities of 16,200 kg/ha of hybrid catfish in the most recent production cycle. While intensively aerated traditional ponds have achieved similar production, traditional ponds without the benefit of increased aeration more typically produce 5,000-6,000 kg/ha.

In-pond raceway systems provide an alternative production method that can substantially reduce chemical treatment costs, improve treatment delivery efficiency and allow new treatments that are cost-prohibitive in traditional pond settings. Several generations of IPRS technology have now been tried on commercial farms, where the sizable reductions in operating costs can help offset inputs whose costs have increased, such as feed and electricity. As designs continue to improve and additional capital and operating cost reductions are realized, the future for IPRS systems is promising.

(Editor’s Note: This article was originally published in the July/August 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Lisa B. Bott

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

203 Swingle Hall

Auburn, Alabama 36849 USA -

Luke A. Roy, Ph.D.

Aquaculture/Fisheries Center

University of Arkansas at Pine Bluff

Pine Bluff, Arkansas, USA -

Terrill R. Hanson, Ph.D.

School of Fisheries, Aquaculture and Aquatic Sciences

Auburn University

203 Swingle Hall

Auburn, Alabama 36849 USA

Tagged With

Related Posts

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.

Intelligence

An engineer’s design for a classroom aquaculture-aquaponics system

An aquaponics teaching system was designed, built and operated by students at the University of Arizona, integrating its operation and management into the educational curriculum. This engineering design will require minimum maintenance and will last years.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.