Industry needs automated equipment to increase yield, profits

Twenty years ago, Solar Aquafarms, Inc. developed an innovative, low-cost method for growing fish and shrimp under closed-cycle, controlled environment systems in southern California. The culture system consisted of solar greenhouses, covered and aerated circular tanks or raceways, and NO biofilters. Instead, wastewater was treated and bioconverted into natural foods within each tank. The method was nicknamed the “ODAS” system, short for “Organic Detrital Algae Soup.” The technology worked successfully for over 10 years, in what was, from 1986 to 1994, the largest recirculating fish farm and the largest tilapia farm in the U.S. This article presents a few of the innovative systems and processes that were developed at Solar Aquafarms while the author was president/CEO of the company (1974 to 92).

Integrated solar aquafarm

The California farm has a total land area of 35 acres, with 18 acres of controlled environment greenhouse systems. All water was treated and recycled on-site. Fish yields averaged 65 to 70 kilograms per cubic meters per year (about 600,000 pounds per acre per year), giving a total production of up to 2,200 metric tons (5.0 million pounds) per year of tilapia, when properly operated and maintained. The facility also contained a hatchery for production of fingerlings yearround, plus finishing tanks for flavor optimization before processing, and a processing facility to produce fresh fillets. From 1987 to 1993 the company sold premium quality fresh tilapia fillets to upscale restaurants and retailers across the U.S. High labor costs for fillets caused the company to switch to selling only live and fresh whole tilapia to local markets.

Solar aquadome culture system

The circular grow-out tanks, called Solar Aquadomes (Figs. 1 and 2), were 29.3 meters (96 feet) in diameter by 2.6 meters (4.0 feet) deep, with a volume of 820 cubic meters (217,000 gallons). Water in each Aquadome was mixed in a circular pattern to spin wastes to a center drain with stand-pipe, sleeve and screen to draw wastes from the bottom. Initially, pure oxygen was injected, with diffused aeration as backup. But oxygen injection plus separate CO2 stripping systems proved too expensive, so paddlewheels became the main aeration method. Although fish densities and yields were lower, costs per pound of fish produced were also lower, and this was more important. Both the paddlewheels and backup oxygen injection were controlled automatically with on-line oxygen meters in each tank. Each Aquadome was capable of producing 55,000 kg (120,000 lbs) of tilapia per year. Net yields per unit of water volume equated to 66 kilograms per cubic meter per year (0.55 pounds per cubic foot per year).

Solar raceway culture system

To expand farm production, raceway tanks were constructed side by side to utilize the remaining land more efficiently. Each raceway is 18.3 meters (60 feet) wide by 146.3 meters (480 feet) long, covered by a solar greenhouse integrated with the raceway walls (Figs. 1 and 3). Water depth averaged 0.8 meters (2.6 feet) and total volume per raceway was 2,080 cubic meters (550,000 gals.). The water was aerated and mixed with paddlewheels at each end (Fig. 3). A center divider and “D” shaped ends created uniform water circulation. A drain at each end of the center divider removed settled wastes. Paddlewheels were controlled by online dissolved oxygen meters in each tank. Each raceway could produce 170,000 kg (330,000 pounds) of tilapia per year, equating to net yields of 72 kilograms per cubic meter per year (0.60 pounds per cubic foot per year).

Feeding system

With demand feeders, tilapia tended to over-eat. Although growth rates were good, feed conversion efficiency was not as good as with timed feed delivery. Bulk feed stored in large bins was delivered to each tank by an auger system, controlled by a timer. Use of floating feed allowed easier observation of fish and adjustment of feeding rates.

“ODAS” for water treatment, natural foods

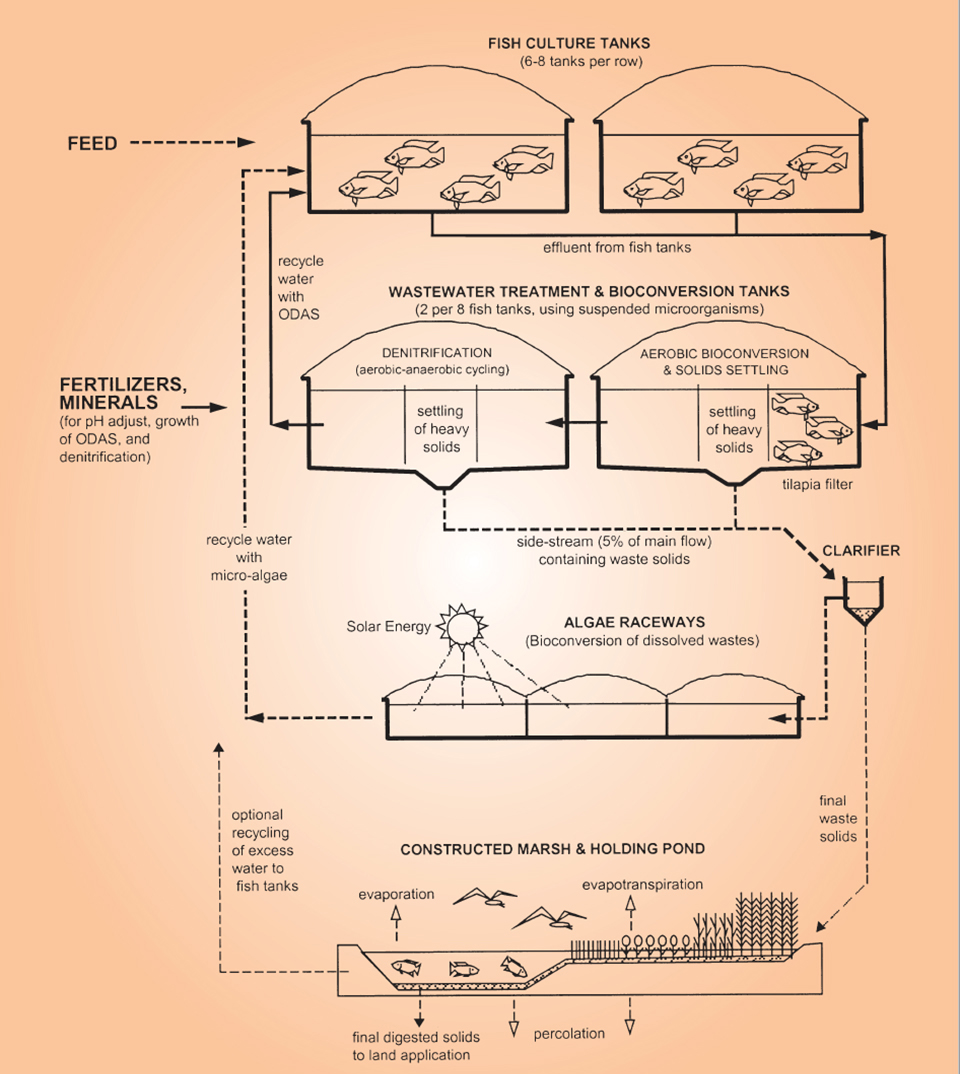

The most unusual technology developed at Solar Aquafarms was a low cost and highly efficient water treatment system and process, called “ODAS,” short for “Organic Detrital Algae Soup.” It consists of a suspended culture of detritus and microorganisms (bacteria, micro-algae, fungi, protozoa), which treat and bioconvert dissolved and particulate wastes into microbial protein. Protein content of the ODAS was 35 to 42 percent. The ODAS was cultured directly in the fish tanks as well as in the “biofilter” tanks. It was consumed by filter-feeding tilapia (as well as marine shrimp and Macrobrachium prawns) as natural food, thereby reducing cost of feed and removal and disposal of solid wastes. Feed conversion ratios – using only a 28 to 30 percent protein feed for tilapia – averaged 1.3:1. A diagram of the treatment process is shown in Fig. 4.

Elimination of artificial substrates, solids filters

The suspended ODAS process eliminates the need for expensive artificial substrates, plus tanks, support structures, pumps, piping and controls for growing attached biofilm organisms, and removing excess build-up. Also, because the ODAS performs its function directly within the fish tanks as well as within “biofilter” tanks, the recycle piping, pumps, “biofilter” tanks and associated controls, valves, and gadgets can be smaller, lower cost, or eliminated.

Water visibility issues

“Clear-water” culture methods are convenient research projects, but for large commercial fish farms, depending on seeing fish in mid- or lower levels of the tanks to assess their health, growth or size, is unreliable and impractical. In practice, most commercial scale, intensive aquaculture facilities with high feeding rates, even when using expensive high-tech recirculation systems, can only see fish near the water surface. The most accurate and reliable method to monitor fish health is daily feed consumption (Fig. 5). For assessing growth rates and fish size, sub-sampling fish in each tank proved best.

Solids management

During initial research with the ODAS process, there was concern that excess ODAS solids might rapidly accumulate, thereby requiring a large solids removal mechanism. Not only was this unnecessary, but the opposite problem (insufficient ODAS) became more of a risk. If tilapia were underfed, they would over-graze the ODAS and thereby cause an increase in ammonia and nitrite. To maintain optimal ODAS solids levels (70-130 milligrams per liter TSS) either the feeding rate, fiber content of the feed, and/or solids settling rate was adjusted monthly.

A portion of the ODAS solids, together with heavy solids (sand, grit) that entered the tanks, was removed daily from the settling tanks and pumped to a solids settling and digestion marsh per lagoon (Fig. 4). The solids in the lagoon digested anaerobically, so net solids accumulation was low (less than 3 cm. depth per year). Any excess solids were applied as a soil amendment to adjacent land. All water pumped to the solids settling lagoon either evaporated, percolated, and/or was recycled to the fish tanks. There was no discharge off-site.

Denitrification

Although a portion of the total nitrogenous wastes was recycled to the fish via the ODAS, nitrate accumulated and needed to be removed via anoxic denitrification. The most cost effective method was to use one of the recycle tanks as a facultative/anoxic treatment stage (Fig. 4). This was done periodically by adding an organic carbon source (molasses, corn syrup, etc.) to increase the carbon to nitrogen ratio, lowering oxygen levels to 0.2 to 1.0 ppm, and mixing with submerged pumps. Denitrification usually occurred within one hour, and the normal flow was then resumed. Denitrification was also done in the marsh/ wetland pond.

Water exchange

Instead of the 10 to 30 percent daily water replacement rate common in most intensive recirculating culture systems, the rate at Solar Aquafarms averaged 0.5 percent of total water volume per day. This volume was not discharged offsite, but went to the solids settling lagoon/marsh for the purpose of removing heavy solids and excess ODAS from the fish system. Make-up water was supplied by a 60 gpm, on-site well, which functioned to replace evaporative losses as well as the net flows to the solids lagoon.

Natural culture methods, probiotics, disease prevention

While the author was president of Solar Aquafarms, Inc., the goal was to produce the highest quality tilapia possible. This included growing, flavor adjusting, and processing the fish using all natural methods, with no antibiotics, hormones or harmful chemicals. This resulted in higher market prices, with little or no increased cost. A second reason to eliminate use of any antibiotics or disinfectants, including ozone or UV systems, was to avoid killing or reducing the effectiveness of the beneficial, probiotic microorganisms cultured in the ODAS. The probiotic bacteria and microbial soup prevented the spread of pathogens by means of competitive exclusion, inhibition, and direct consumption. No disease problems occurred with tilapia, hybrid striped bass, pacu, freshwater prawns, or marine shrimp cultured with this process over a 15-year period.

Economics

Intensive culture systems have a reputation for being uneconomical due to high operation and construction costs, and high risks. This is particularly true for super-intensive culture systems using tanks inside buildings, with pure oxygen, carbon dioxide stripping, and elaborate biofiltration systems. In contrast, Solar Aquafarms was designed and operated to combine the best features of ecological pond culture with higher yield, controlled environment methods, in order to reduce both costs and risks.

Total direct production cost for live fish delivered to the processing plant, including flavor adjustment in finishing tanks, labor, feed, utilities, hatchery costs, and maintenance of facilities, averaged only about 55¢ per lb of fish. This is similar to or lower than the cost of tilapia production in many tropical countries using earthen ponds and low cost labor. The construction cost of the controlled environment culture systems was also relatively low. Total cost of the hatchery and grow-out systems, including tanks, greenhouses, piping, aeration, auto feeders, and size grading/harvesting equipment, equated to about $1.00 per pound of annual production capacity. This is similar to the cost of conventional extensive earthen pond systems, such as modern catfish pond systems with aeration and piping, on a per pound of annual production capacity basis.

The problem at Solar Aquafarms was the high cost of labor in the U.S. to produce and package premium quality fillets, combined with the relatively low meat yields of tilapia (31 to 34 percent fillet when skinless, boneless and fully trimmed). A variety of automated equipment was tested in an attempt to reduce processing labor costs. Although the equipment could produce fillets with less labor, the extra fillet meat lost (3 percent) compared to hand filleting did not result in lower product costs per pound of final fillet. If automated equipment is ever developed that will give a high meat yield from tilapia, or if tilapia are genetically engineered to fit existing processing equipment, tilapia grown in the U.S. for the fresh fillet market, using the above methods, could become very profitable.

Recent applications

Since 1992, the author has continued to test, develop and improve the technology with other saltwater and freshwater species. Since 1996, as Director of Aquaculture for Mote Marine Laboratory, he has used the closedcycle, controlled environment ODAS process to successfully raise snook, four species of sturgeon, red snapper, and pompano in pilot scale projects.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Steven A. Serfling

Director of Aquaculture

Mote Marine Laboratory

Sarasota, Florida USA[103,114,111,46,101,116,111,109,64,115,97,115]

Tagged With

Related Posts

Health & Welfare

Animal welfare: Growing factor in international aquaculture

Although concerns for the animal welfare of food animals are currently highest in the United Kingdom and European Union, they are also growing in other parts of the world.

Health & Welfare

Born in Hawaii, SPF broodstock shrimp industry faces globalization

The next step for shrimp breeding will be developing animals that aren’t just disease-free, but increasingly resistant to multiple pathogens. The industry is globalizing, with suppliers setting up shop overseas. But its birthplace will always be Hawaii.

Intelligence

Research, extension efforts support hard clam industry in Florida

Breeding research is pursuing a hardier hard clam strain to improve survival during Florida’s hot summers. Diversification would support additional growth.

Responsibility

White House awards hint at aquaculture’s potential in the United States

The latest Champions of Change awards celebrated the work of change-makers in sustainable seafood, from chefs to fishermen to aquaculture advocates. With innovation and perseverance, the industry may soon meet its vast potential.