Producers now tapping into export markets

Modern culture of marine fishes in Spain began around 25 years ago, but commercial production only started about 12 years ago, based on the culture of sea bream (Sparus aurata). Companies that pioneered sea bream culture had to develop on their own the relatively complex techniques for larval rearing of this fish, essentially through trial and error. Support from the official sector and universities for this research and its adaptation for commercial production was always limited, although these companies did share their advances among themselves and with similar companies and institutions in France and Italy.

Following a deep crisis in the early 1990s, only a few hatcheries with cutting- edge technology and enough financial support survived. Since then, the number of companies involved in sea bream production has barely increased, and hatcheries have produced sea bream fingerling numbers well above the needs of national market demand, exporting the excess production to other Mediterranean countries. Because of this, Spain has maintained a stable growth in fingerling production.

Currently, there are eight sea bream hatcheries in Spain, distributed along the country’s coastline. Sea bream production in 1998 was 36 million fingerlings, and in 1999 production was expected to increase to almost 45 million. About one-third of the production is exported, mostly to Portugal, Italy, Greece and Malta. These hatcheries also produce fingerlings of other commercially important fishes, such as sea bass (Dicentrarchus labrax), flounder (Solea senegalensis) and others.

Fingerling production process

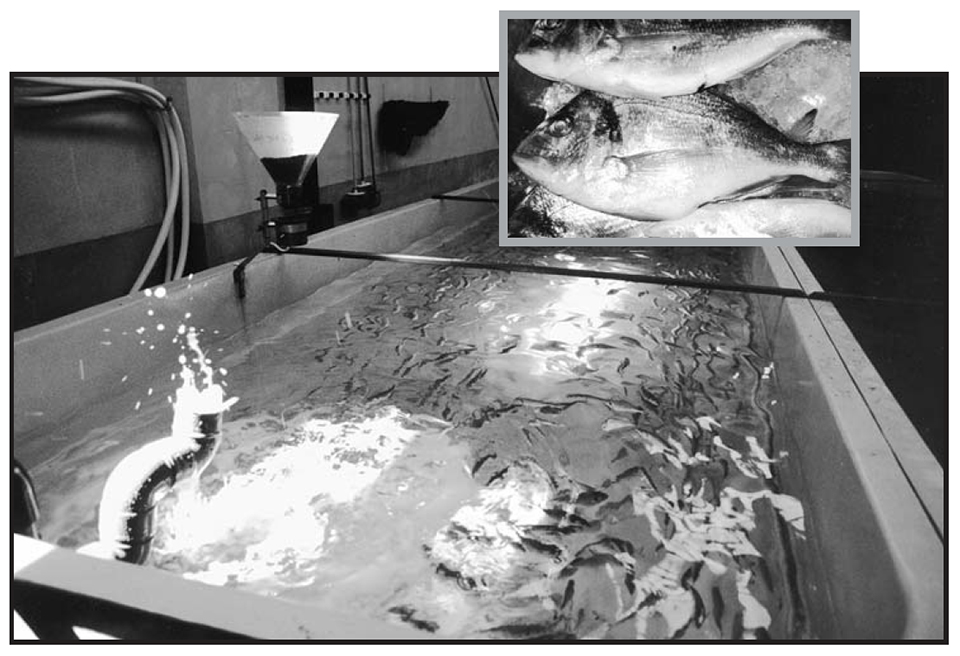

The production of sea bream fingerlings is complex and begins with broodstock. Originally, all broodstock used was wild-caught, but with time this practice is being replaced with the use of captive-born and bred animals – in some cases this has already been underway for a number of generations. However, any genetic improvement is still imperceptible. Eggs have a diameter of about one-mm, and larvae are very small and relatively primitive, with no resemblance to the adult animal. They have no digestive tract and must survive by consuming their yolk. They move very little and float around on the water surface. At around four days after hatching, they begin to feed, requiring live feeds like rotifers and microalgae, followed by artemia. Live feeds are necessary during the first month or so after hatching. At four months, the average weight is around 2 grams, and this is the usual market size for sea bream fingerlings.

Demand for large fingerlings

In recent years, the demand for larger fingerlings up to 10 to 15 grams has increased, due to the expansion of the cage grow-out industry, which requires larger fingerlings for stocking due to the harsher conditions in these cages compared to land-based grow-out systems. Fingerling producers have had to modify their facilities to be able to grow larger animals, and this has been accomplished by increasing tank volume and water flow. Where these modifications have not been possible, new companies specializing in “pre-grow-out” have come online. These companies take the 2-gram fingerlings from traditional hatcheries and grow them to the 10- to 15-gram animals required for stocking into sea cages. There is close contact and cooperation among all involved, from the original hatcheries through the new pre-grow-out facilities and to the cage grow-out companies.

In the wild, sea bream spawn naturally from December to May, but through environmental manipulation and control it is now possible to spawn sea bream broodstock year round. This allows grow-out companies to purchase fingerlings whenever they need them. Most of these companies buy and stock seabream fingerlings throughout the year, which allows them to have product for the market at any time.

Quality of fingerlings

Fish quality has always been a priority for Spanish producers of sea bream fingerlings, and a challenge they had to face and overcome in a stepwise manner. During its early years, the industry’s biggest challenge was to produce sufficient fingerlings to supply their own needs. Then it had to reduce to acceptable levels the problems of deformities and malformations. And then the industry had to work on production methods that yielded uniform size fingerlings.

Nowadays, having successfully overcome all these problems, the main area of improvement is preventive health – including vaccination – although there are no serious disease problems threatening the industry.

Transport to grow-out farms

Fingerlings are transported from hatcheries to grow-out farms by road using live haul trucks properly fitted with aeration and oxygenation systems. There are several specialized, live hauling companies, which transport fingerlings within Spain and to other countries in Europe and Northern Africa. About 100,000 to 500,000 fingerlings are sent in each shipment, and travel time can be as long as one week. Occasionally, fingerlings are also shipped by air.

(Editor’s Note: This article was originally published in the April 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Javier Ojeda González-Posada, M.S.

Technical Director

Esteros de Sancti Petri SA

Chiclana, Spain

Tagged With

Related Posts

Health & Welfare

Botanical extracts improve productivity of shrimp, pangasius

In a study with pangasius, dietary administration of a blend of botanical extracts improved performance, reducing intensity of gill parasite infestation.

Health & Welfare

Aquaculture genomics: Progress in identifying species genetics continues

The continued application of genome research to aquaculture will provide unprecedented accuracy for genetic selection of performance and production traits.

Health & Welfare

Advances in fish hatchery management

Advances in fish hatchery management – particularly in the areas of brood management and induced spawning – have helped establish aquaculture for multiple species.

Health & Welfare

Algae alternatives serve in larval rearing of sea bream

Sea bream fry are produced using the greenwater technique in which microalgae are added to larval-rearing tanks during the first 20 to 30 days after hatching.