Study reports on static vs. turning methods, microbial community changes

The food processing industries in the European Union generate a large quantity of waste products, estimated to be 35 megatons (equivalent to a million metric tons) per year. Of this, 60 percent is organic material. The seafood processing industry produces effluent with a high content of fish remains and oils, as wastewater with a high organic load.

Composting is one of the most widely used techniques for the management of organic sludge during wastewater treatment. The process biologically degrades solid organic substrates under aerobic conditions through the action of diverse microbial populations. This process produces a stable, humified (converted to humus, the mature or natural compost) product that is suitable for land application as a soil improver and as a source of organic matter and nutrients. The significant availability of nutrients in organic waste promotes microbial growth and with it an elevation in temperature and, consequently, the succession of different microbial communities which appear at different stages of the composting process.

There are few studies related to composting of seafood processing sludge and even fewer dealing with the maturation phase. Previous research studied the maturation of seafood processing sludge compared to that for swine manure and sludge from an urban wastewater treatment plant and demonstrated that the seafood processing sludge used contains a high level of biodegradable substrates, which cause it to reactivate when left to mature after an intensive period in a static reactor.

This article – adapted and summarized from the original – evaluated if static and turning management during composting of seafood sludge influence the physico-chemical and biological parameters and the microbial-community structure throughout the maturation phase, and if controlling the maturation phase produced a more stable product faster.

We thank the research support services of the University of Vigo (CACTI) for the carbon and nitrogen analysis, and also Emilio Rodríguez Cochón, Domingo Pérez Díaz and Josefina Garrido González for their help and technical support.

Study setup

The wastewater sludge used came from a from a plant that produces pre-cooked and flash-frozen fish and cephalopods; it was obtained after fats had been separated from the sludge and the waste product had been treated with coagulants and flocculants. Pinewood shred to smaller than 3-cm pieces was used as a bulking agent.

Composting was carried out in two stages with the objective of simulating waste product management like in industrial composting facilities. The sludge and bulking agent mixture was composted in a 600-liter-capacity static reactor; aeration was provided through programmed forced ventilation of 400 cubic meters per hour. by a periodic flow rate of 30 seconds every 90 minutes, and an alarm flow for temperature and oxygen control. The material was kept in the reactor, where it underwent the intensive stage, until the temperature had dropped to below 35 degrees-C. The reactor was emptied and the homogenized material placed in triplicate, 200-liter wooden boxes where the cooling, stabilization and maturation stages took place (henceforth called the maturation phase).

Two composting tests were carried out using the same mixture and handling in the reactor; each test, however, received a different treatment in the wooden boxes, either static treatment or turning treatment for temperature control. The boxes that received the static treatment were left for 112 days without being homogenized, whereas the ones that received the turning treatment were mixed when temperatures exceeded 55 degrees-C, to aerate, avoid excess temperature and homogenize the compost. The boxes had oxygen and temperature control checks daily for the first 42 days, and three times a week afterwards until the end of the 112-day process. Material samples were collected periodically for lab analyses.

For detailed information on the experimental and composting designs; composting parameters; and statistical analyses, refer to the original publication.

Results and discussion

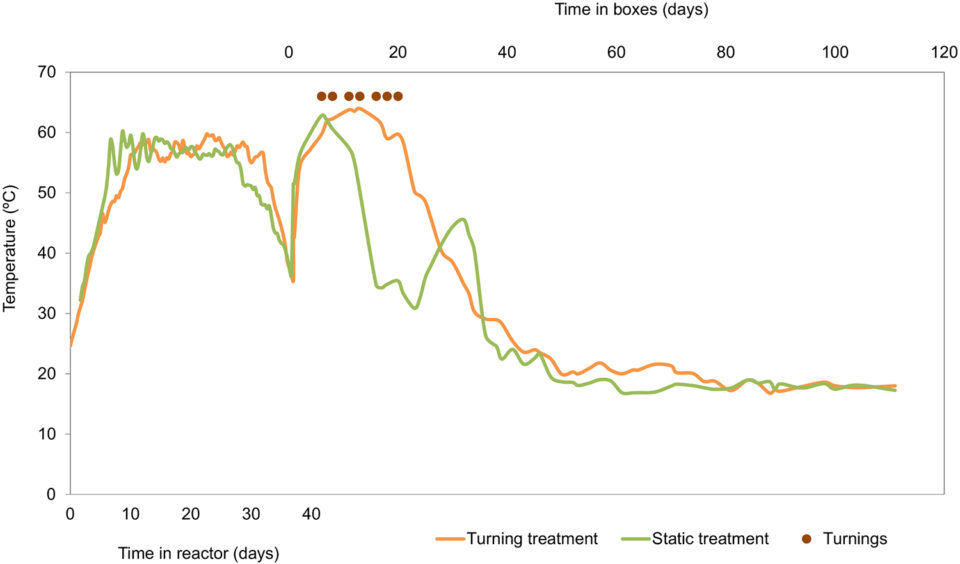

The temperature profile of the composting material during the reactor phase was similar in both treatments, and there were no significant differences. The temperature slowly increased at the start of the process, reaching over 45 degrees-C starting on the fifth day. Both tests maintained thermophilic temperatures [typically over 41 degrees-C) for 28 days. After emptying the reactors, the reactivation of the process with thermophilic temperatures was quickly reached in the box tests (Fig. 1).

However, the temperature evolutions of the two treatments during maturation were significantly different. In the static treatment the temperatures constantly remained in excess of 45 degrees-C for ten days, with a second peak temperature being registered on the 23rd. On the 14th day it was necessary to remoisten the material in order to keep moisture levels above 40 percent. During the turning treatment the composting material was turned seven times over a period of 20 days; the material was remoistened during three of these turns and thermophilic temperatures were maintained for 26 days.

The temperature profiles of both tests while in the reactor, corresponding to the intensive stage, showed patterns typical of the composting process; in other words, temperatures increasing to thermophilic levels, stable temperatures, and a subsequent decline in temperature until it reached mesophilic [typically 20 to 45 degrees-C] levels.

Turnings done during the first several days after placing the material in the boxes facilitated the extension of thermophilic conditions more so than the static approach. And it reactivated the process of incorporating the least degraded material and, as a result, made it possible to supply easily assimilable substrates to the microbial biomass, starting from the exterior of the boxes and moving inwards.

Lengthening the thermophilic phase with forced ventilation was possible by turning the seafood sludge after the static reactor composting. At most composting facilities, turnings of the pre-composted waste in the maturation stage are not based on the biological process but on industrial criteria (increased space, moving the material to another location, drying the material), so the implementation of protocols for the maturation stage is considered important to improve the composting process.

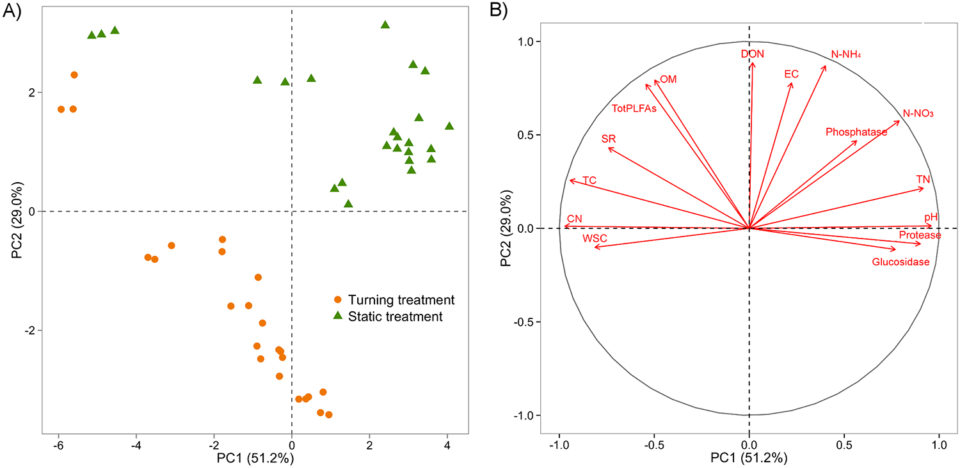

The treatment applied while the material was in the boxes determined its physico-chemical and biological development during compost stabilization and maturation. Turning the material during the maturation stage allows for the compost to degrade to a greater degree, suggesting that the time needed to achieve stability is reduced when the process control is under dynamic conditions. Other authors have found similar results with regards to all stages of the composting process, and not only the maturation stage in particular.

Our results showed that turning pre-composted waste along temperature criteria following static reactor composting affected the pH, electrical conductivity, ammoniacal nitrogen, dissolved organic nitrogen, organic matter, enzymatic activities, total nitrogen and total carbon. The result was the compost becoming stable in less time than through static conditions for the maturation stage. Turning-treatment samples starting from the 56th day showed stable conditions; some parameters, like the respiration rate and the germination index, for example, were improved by prolonging the process.

Turning the decomposing material significantly affected its physico-chemical and biological characteristics as well as its microbial activity, making it possible to achieve a more stable and more mature product in less time than the unturned material.

Therefore, the stabilization of the mono/sat ratio can be indicative of mature compost. Bacterial population stabilization – as a result of running out of easily degradable substrates – can indicate the degradation of more calcitrant compounds. Therefore, turning the material while it is in the maturation stage allows for a greater degree of organic matter degradation and microbial succession towards a more stable mesophilic community, reflecting compost maturation.

Perspectives

The fresh compost turning approach made it possible to maintain temperatures and, as a result, prolonged the thermophilic phase; this allowed for a high level of organic matter degradation over a longer period. Controlling the composting of high energy waste through the turning treatment after the most intensive stage in the reactor produced stability and maturity faster than statically treating pre-composted waste.

References available in original publication.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Iria Villar

Department of Ecology and Animal Biology

University of Vigo

Vigo, Pontevedra, Spain -

David Alves

Department of Ecology and Animal Biology

University of Vigo

Vigo, Pontevedra, Spain -

Salustiano Mato, Ph.D.

Department of Ecology and Animal Biology

University of Vigo

Vigo, Pontevedra, Spain

Tagged With

Related Posts

Responsibility

Aquaculture ponds hold carbon

Although 16.6 million metric tons of carbon are annually buried in aquaculture ponds, estimated carbon emissions for culture species have approached several metric tons of carbon per metric ton of aquaculture product.

Responsibility

Drying, liming, other treatments disinfect pond bottoms

The traditional way of destroying organisms in pond bottoms is thorough dry-out for a week or longer. Fish toxicants and liming can kill unwanted parasites.

Responsibility

Appraising pond liners for shrimp culture

The use of plastic-lined ponds by shrimp farmers can significantly improve production efficiency, support more production cycles per year, and higher mechanical aeration rates and stocking densities. The capital cost of lining ponds can be very significant, so a thorough feasibility analysis is recommended when considering this production tool.

Aquafeeds

Waste not: Novel protein-recapture initiatives for aquaculture

A Norwegian fermentation technology firm utilizes volcanic matter to transform salmon waste, including feces and uneaten feed, into a high-protein powder.