Systems evaluated by coefficient of performance

Temperature manipulation of water in a hatchery or other land-based aquaculture operation can be a critical part of operations and a significant expense. Refrigeration equipment is commonly used to lower water temperatures, and in the form of a heat pump, it can be used to raise temperatures, as well.

Unfortunately, the equipment used can often be complicated and require specialized training to select, install and maintain. In most jurisdictions, a license is required to test, adjust or repair any component of refrigeration and/or air-conditioning machinery contained in a refrigeration system.

Challenges

There are three main challenges facing refrigeration and aquaculture. Firstly, given the nature and size of many aquaculture facilities, daily operation of the refrigeration equipment may fall to someone with no formal training or specific knowledge in refrigeration.

Secondly, local refrigeration mechanics may not fully understand the application of refrigeration to aquaculture. Most local refrigeration companies deal with residential and commercial air-conditioning systems, supermarket-style refrigeration and freezer systems, and/or commercial freezers. These applications are well documented and fairly consistent in their nature.

In aquaculture, however, it is not uncommon to ask a refrigeration system to compensate for water flow and temperature adjustments, fouling of heat exchanger surfaces and fluctuations in ambient air and water temperatures.

Thirdly, aquaculture-specific chillers are not commonly found at local hardware stores or even local refrigeration wholesalers. Rather than facing the costs of custom engineering design, local refrigeration contractors may offer piecemeal solutions that work, but only if the first two challenges can be overcome.

Refrigeration for aquaculturists

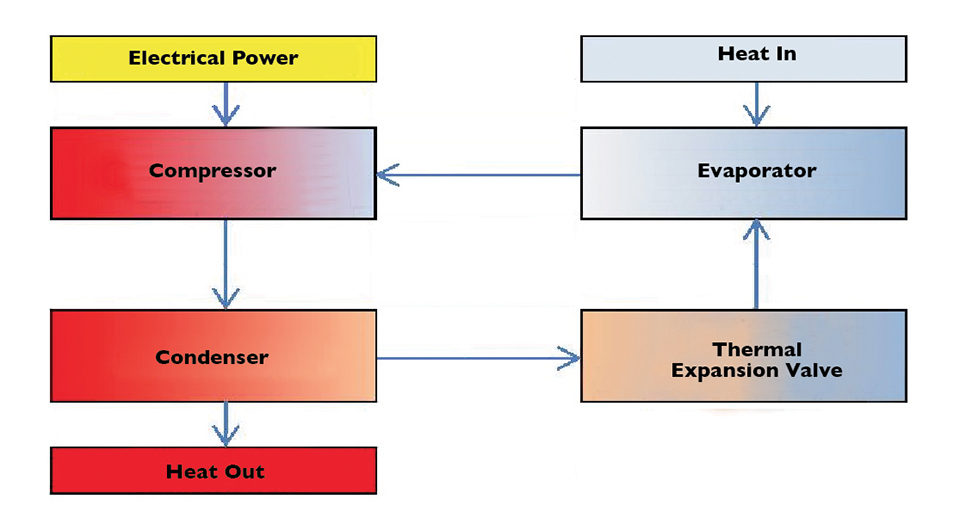

While most common heating systems, such as oil furnaces, electric heaters or woodstoves, generate heat and then distribute it, the basic premise of refrigeration is to move heat from a normally colder heat source to a normally warmer heat sink. A refrigeration system consists of five main components: refrigerant, compressor, condenser, thermal expansion valve (TXV) or other metering device and evaporator. Basic refrigerant flow is shown in Figure 1.

Refrigerant enters the compressor as a gas, where it is compressed and pumped to the condenser. In the condenser, refri-0gerant changes from a gas to a liquid. The condensing process is exothermic or heat-releasing, and must be used to heat another fluid. In water chillers, ambient air is often used, depending on the design of the condenser.

Leaving the condenser, refrigerant is metered through the TXV into the evaporator. In the evaporator, refrigerant changes from a liquid to a gas. The evaporation process is endothermic or heat-absorbing, and requires a heat source – the process water in a water chiller. From the evaporator, refrigerant returns to the compressor as a gas, thereby completing the cycle.

In most systems, the TXV is often the only component that can react to load changes that occur in the evaporator in response to flow or temperature changes, or fouling of the heat transfer surfaces. Air-cooled condensers often have pressure-controlled fans that cycle on and off to accommodate changes in condenser loading. A thermostat is commonly used to shut the whole unit off once the target temperature is reached.

Common pitfalls

When operating a refrigeration system, intuition may not be your best friend. Common pitfalls are a lack of water flow, inadequate evaporator capacity, freezing of the evaporator and no notation of baseline performance.

The most common pitfall is a lack of water flow. If your chiller is rated to remove 2 degrees C at 100 Lpm, do not expect it to remove 4 degrees from 50 Lpm unless it was designed to do so. Since most compressors run at full speed only, as flow rates drop in an evaporator, the process water temperature difference from inlet to outlet should increase. But as temperature difference gets out of range, problems begin.

Thermal expansion valves sense a smaller loading in the evaporator as colder refrigerant. They react by restricting the refrigerant flow into the evaporator in an effort to maintain the temperature for which they were initially set. This causes a further decrease in pressure/temperature in the evaporator and can overheat the compressor by starving it of the refrigerant it often uses for cooling itself.

Repeated or extended operation in this condition causes the compressor oil to degrade, and often electrical shorting begins to occur, causing compressor failure. Note the performance and rated flows for your system and operate within those ranges. If this is not possible, consider changing to a side loop system if at all possible. A side loop system may not be ideal from a pumping perspective, but from the chillers’ perspective, it is perfection due to the consistent loading and smaller temperature range in the chiller.

Evaporators

Evaporators are often selected for highest expected flow rate and highest expected temperature difference with no consideration given to other conditions in which the evaporator may be expected to perform. A general rule of thumb is that half the flow requires double the evaporator heat transfer surface.

As the operating temperature lowers in the evaporator, the evaporator heat transfer surface should increase. Properly matching the evaporator to the application and properly matching the other components to the evaporator can double the evaporator efficiency. Practically speaking, this means half the power input is required to achieve the same quantity of chilling.

Evaporator capacity can also be affected by fouling of the refrigerant coils. Any particles or biofilms that adhere to the coils decrease the heat transfer rate from refrigerant to process water and thus decrease the evaporator capacity. Depending on the system, annual or semiannual cleaning of the coils should prevent this from having a serious impact on chiller performance or life expectancy.

Freezing in the evaporator can cause refrigeration system failure. When flow through the evaporator gets too low, ice can start to form inside the evaporator and act as an insulator, causing refrigerant to pass through the evaporator without completely evaporating. If the incompressible liquid exits the evaporator and reaches the compressor, it is likely to cause irreparable compressor damage. Refrigeration contractors should be able to determine if this is occurring at the minimum flow and adjust the thermal expansion valve accordingly.

Another common pitfall in aquaculture chiller systems is having the water flow stop while the chiller continues to run. Given enough time, this will freeze the water inside the evaporator and cause it to split open. If the ice splits a refrigerant pipe as well as the evaporator casing, replacing the entire system may be cheaper than repairing it. A simple flow switch should be installed to shut down the chiller, should the water flow stop.

System performance

Every operator should have a baseline performance measurement for the chiller system, which is helpful when a performance issue occurs. It will also aid in demonstrating to refrigeration contractors what you need from your system.

To get a performance measurement, record the flow and temperature of water entering and leaving the chiller barrel, the compressor voltage and the compressor amp draw, all while the chiller is running full on. If you operate at different temperatures, do this at each temperature to get a complete picture of your system’s performance.

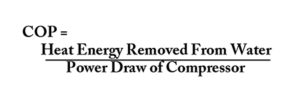

A refrigeration system’s performance is measure by its coefficient of performance (COP). In the case of a typical aquaculture chiller system:

A good target COP value is 4, meaning the amount of energy you transfer out of the water is 4 times the amount of energy for which you pay the power company. But you have to determine what is good for your system.

A good target COP value is 4, meaning the amount of energy you transfer out of the water is 4 times the amount of energy for which you pay the power company. But you have to determine what is good for your system.

Depending on the various components used, a COP lower than 4 may be the best your system can achieve. If your system has a COP less than 2, a complete performance evaluation by a knowledgeable refrigeration contractor or engineer would likely help extend its life and reduce your power bill.

(Editor’s Note: This article was originally published in the September/October 2010 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Philip Nickerson, P.Eng.

Scotian Halibut Ltd.

P. O. Box 119

Clarks Harbour, Nova Scotia

B0W 1P0 Canada

Related Posts

Intelligence

As ocean temperatures rise, so too will vibrio outbreaks

A study using a half-century of data has linked climate change and warming sea temperatures with an increase in illnesses from the common vibrio bacteria. Shellfish growers, fighting a particularly virulent strain of Vibrio parahaemolyticus, are changing their harvest protocols.

Health & Welfare

New approaches can help ensure safety of raw farmed oysters

Practical post-harvest oyster processing methods are needed. Preliminary studies evaluated the potential of high-salinity relaying to control Vibrio levels in raw oysters.

Health & Welfare

Phytogenic feed additives improve performance, antioxidants in rainbow trout

A study conducted to investigate the effects of encapsulated and non-encapsulated phytogenics derived from plants on the performance and antioxidant status of farmed rainbow trout.

Intelligence

Post-harvest quality of freshwater prawns, part 2

Freshwater shrimp can contain pathogenic bacteria that cause illness unless care is exercised by producers, retailers and consumers. Many of the human pathogens can survive frozen storage, but are killed or inactivated by thermal processes.