Turning a cost-ridden byproduct into a revenue stream

Gelatin is traditionally produced by hydrolysis of bones and skins from cattle and pigs. This can create problems for people with kosher and halal dietary restrictions, and also carries the potential of health hazards associated with outbreaks of bovine spongiform encephalopa.

Research performed by the authors as part of a larger USDA Agricultural Research Service project designed to convert underutilized Alaska fish byproducts into value-added ingredients and products found that gelatin derived from fish skin collagen may provide a convenient substitute.

The gelatins of coldwater fish skins differ from other gelatins in gel set and melting temperatures. Skins from coldwater fish produce a gelatin that does not solidify at room temperature, making it difficult to directly substitute for gels prepared from the skins of cattle, pigs and warmwater fish. This is actually an advantage, since it imparts unique functional properties that are not present in other gelatins.

Gel strength

Fish skin gelatins have fewer proline and hydroxyproline amino acid residues than their mammalian counterparts. Since these residues help stabilize the gelatin’s helical structure, gelatins that contain fewer of them have a lower gelation temperature and decreased gel strength.

Gelatins prepared from cattle hides, bones and pigskin each displayed more gel strength and higher gel-setting temperatures than any of the fish skin gelatins tested. Differences in gel strength among fish skin gelatins depended upon whether the fish were from warm- or coldwater environments.

The authors’ study comparing Alaskan pollock and salmon skin gelatins with commercially available warmwater fish skin gelatins demonstrated that gel strength and gel-setting temperatures were lower for coldwater fish gelatins than for their warm-water counterparts. Other physical, chemical and rheological properties varied among the different gelatins according to their molecular weight distributions and unique amino acid compositions.

Gelatin films

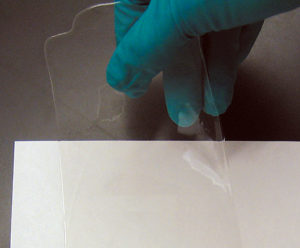

Fish skin gelatin can also be made into thin, transparent films that are stable at room temperature. Gelatin films are usually judged by their tensile strength, puncture resistance and elasticity. These parameters individually affect the functionality of the film and determine its usefulness for edible coatings and other food and feed applications.

Alaskan pollock skin gelatin films have lower tensile strength and puncture resistance than films prepared from warmwater catfish skin gelatin. Films produced from cattle hides and pigskins have higher tensile strength, puncture resistance and elasticity than films from either coldwater or warmwater fish.

Edible films and coatings are emerging as an important tool for reducing water vapor loss and controlling the oxygen permeability of perishable foods. Films cast from coldwater fish skin gelatins can provide unique barrier characteristics when compared to cattle and pigskin gelatins.

Films made from both warmwater and coldwater fish skin gelatins pass significantly lower amounts of water vapor and oxygen than films derived from cattle hides and pig skins. This trait could prove useful in preparing edible films and coatings for foods and feeds, encapsulating drugs and reducing water loss in refrigerated and frozen foods.

Microbial safety

As fish skin gelatin gains popularity, safety issues may become a concern. Bacterial contamination of gelatin is a well-documented problem, since gelatin can provide nutrients that support the growth of microorganisms. Most bacteria are destroyed by the high temperatures and pH extremes associated with gelatin production, but postprocessing contamination can still occur.

This problem can be controlled by incorporating antimicrobial compounds directly into fish skin gelatins. When fish skin gelatin gels and films were fortified with a food-safe enzyme called lysozyme, some groups of Gram-positive spoilage bacteria were inhibited. The lysozyme-enhanced gels and films proved effective against spore-forming Bacillus bacteria at concentrations as low as 0.01mg/ml without adversely affecting gel clarity, pH or gel-set temperature. Antimicrobial activity was retained during storage, despite the drying process involved in the production of gelatin films.

Disruption of the gel network can occur when foreign compounds are introduced. The addition of lysozyme slightly decreased the strength of fish skin gelatin gels. The barrier properties of the gelatin films were also compromised, as demonstrated by an increase in water vapor permeability in the lysozyme-enhanced film. The greater the quantity of lysozyme added, the more pronounced the detrimental effects.

Cost to benefit

Byproducts such as fish skins from Alaska’s fishing industry represent an underutilized resource often subject to disposal costs rather than economic benefits. Currently, fish-processing operations can mechanically separate skins from other fish components during the production of boneless fillets, making the collection of discarded skins economically feasible.

These fish skins can be stabilized by various drying techniques without seriously hindering the yield and quality of extracted gelatin. Dried fish skins substantially decrease transportation costs and facilitate storage, perhaps eventually leading to widespread production of high-value fish skin gelatin of acceptable quality for food, aquaculture feeds and pharmaceutical uses.

(Editor’s Note: This article was originally published in the July/August 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

C.K. Bower

Subarctic Agricultural Research Unit

USDA-ARS Pacific West Area

University of Alaska

360 O’Neill Building

Fairbanks, Alaska 99775-7220 USA -

R.J. Avena-Bustillos

Processed Foods Research Unit

USDA-ARS Western Regional Research Center

St. Albany, California, USA -

C.W. Olsen

Processed Foods Research Unit

USDA-ARS Western Regional Research Center

St. Albany, California, USA -

D.A. Olson

Processed Foods Research Unit

USDA-ARS Western Regional Research Center

St. Albany, California, USA -

T.H. McHugh

Processed Foods Research Unit

USDA-ARS Western Regional Research Center

St. Albany, California, USA

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Responsibility

Aquaculture byproducts improve sustainability of seafood value chains

Tons of aquaculture byproducts are available as sources for fishmeal and fish oil to supplement the supplies obtained from fisheries. Innovative technologies are supporting more efficient use of these by-products in aquafeed.

Health & Welfare

Biofloc technology holds potential for carnivorous fish species

Juvenile carnivorous African catfish performed well in biofloc-based systems, which could help produce better quality and more disease-resistant seed of this important aquaculture species and support the expansion of African catfish farming industry.

Intelligence

Byproduct utilization for increased profitability, part 2

Enzymes obtained from fish- and shellfish-processing wastes can be used in the making of a number of useful products. Lipase enzymes from fish can break down lipids, while amylases hydrolyze starch.