New Thai Royal Frozen Foods facility signals industry’s modernization

Thailand first began exporting frozen seafood in the 1960s. Since that time, seafood exports from Thailand have increased at an exponential rate. Thailand’s traditional seafood exports have been raw shrimp, fish, squid, cuttlefish, and clam products – either in block form or individually quick frozen (IQF).

Over the past 10 years or so, there has been an increase in demand for more value-added and ready-to-eat seafood items. This is a direct result of Thailand’s reputation of being able to produce top-quality seafood products. However, the increase in value-added production has required strict food safety and quality-assurance programs. Due to these stringent controls and exacting specifications from customers, Thai food processors are continually upgrading their production facilities.

Keeping pace with growth

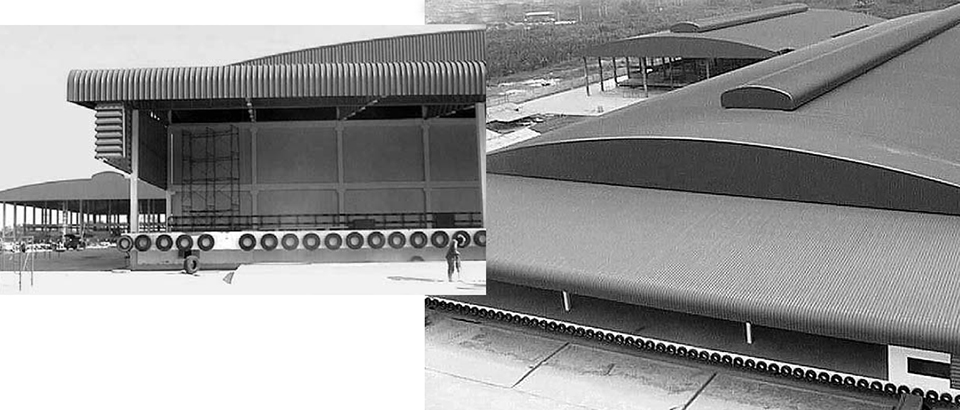

Thai Royal Frozen Foods Co., Ltd. recently made the commitment to construct a large, state-of-the-art processing facility in Mahachai, Thailand. This new plant, with over 11,100 square meters of production floor space, was designed to process a full range of value-added items, as well as block and IQF products.

The concept was to place under one roof all of the production steps, from receipt of raw material to cold storage of the final products, in order to improve efficiency and cost effectiveness of the process flow. To assure adequate cold storage during the crucial peak packaging months, when cold storage space it at a premium, the new facility was equipped with over 5,500 square meters of cold storage space.

Design aspects

Walls, ceiling, and floors

The walls and ceiling in the production areas are insulated with Isowall panels, which sandwich a 7.6-mm thick core of insulation between two sheets of painted sheet metal. Due to the tropical outside temperatures in Thailand, Isowall panels with a thickness of 25.4 mm are used in the cold storage rooms. The smooth surface of the panels is very easy to clean and facilitates proper hygiene. The production room flooring is terrazzo with no seams or joints, which also contributes to efficient cleanup.

Refrigeration

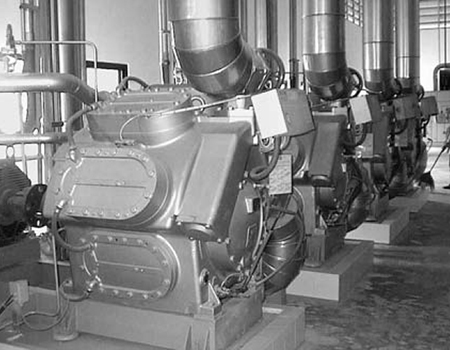

Ammonia was chosen as the refrigerant for the plant, due to its efficiency, dependability, and environmental compatibility. The 270-hp compressors were imported from Europe.

Freezing equipment

Two types of cryogenic freezing are used in the IQF freezing lines. Thai Industrial Gas supplies the liquid nitrogen and Praxair Thailand Co. supplies the carbon dioxide.

Ice supply

All ice is made on site. To avoidcross- contamination between the highand low-risk production areas, two separate ice plants were installed. The capacity of each plant is 41 metric tons (MT) per day.

Cooking equipment

Inline, steam-injected cooking tunnels are used. Each tunnel consists of three individually controlled cooking zones, which ensures thorough, uniform cooking.

Water treatment

All water used in production is pretreated with chlorine dioxide. Chlorine dioxide has proven to be one of the safest, most effective methods of ensuring the water is always free of harmful microorganisms. The compound is produced on site in a Bello Zon chlorine dioxide generator, supplied by ProMinent Fluid Controls. The generator creates a chlorine-free solution of chlorine dioxide through the reaction of sodium chlorite solution with hydrochloric acid. The dosage rate is automatically monitored, so there is no fluctuation in the residual chlorine levels.

Conclusion

Since 1995, Thailand has been the world leader in producing and exporting seafood products of the highest quality. Major seafood companies are showing their faith in the future of the Thai industry by investing in ever-larger, more efficient and more stringently controlled processing plants. These are essential steps in the growth and maturity of the aquaculture industry.

(Editor’s Note: This article was originally published in the February 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Brad Kelly

Thai Royal Frozen Foods Co., Ltd.

Tambon Mahachai

Amphur Muang, Samutsakorn, Thailand

Tagged With

Related Posts

Intelligence

All about Listeria

The pathogenic bacterium Listeria monocytogenes is present in the environment and easily transferred to food and food contact surfaces.

Responsibility

An African prison where fish will be farmed and lives saved

A nonprofit organization working to improve conditions in African prisons is hoping tilapia ponds, tended to by inmates, will aid in their nutrition. A small donation from the Global Aquaculture Alliance will go a long way.

Intelligence

Commercial implementation of in-pond raceway system

An in-pond raceway system in Alabama was utilized to supply various niche markets, including Asian grocery store chains that desired fresh live fish, recreational pond stocking businesses, private pond owners and fee fishing operations. In many cases, a higher price was achieved.

Aquafeeds

Inside the Cargill Aqua Nutrition aquafeed plant in Scotland

Formed in 2015, following Cargill’s acquisition of salmon feed specialist EWOS to complement its own warm-water aquaculture feed business, Cargill Aqua Nutrition produces feed for salmon, tilapia and shrimp in 20 countries around the world.