Feed-based medicines could reduce labor costs and stress

With many aquafeed ingredients becoming more expensive and/or harder to find, grain-based feeds – particularly those based on corn – are receiving more attention. Now scientists are developing vaccines for the animal healthcare market that can be delivered directly through corn grain. By coupling the vaccines with conventional feed formulations, vaccines can be customdelivered with no more effort than feeding fish at customary levels.

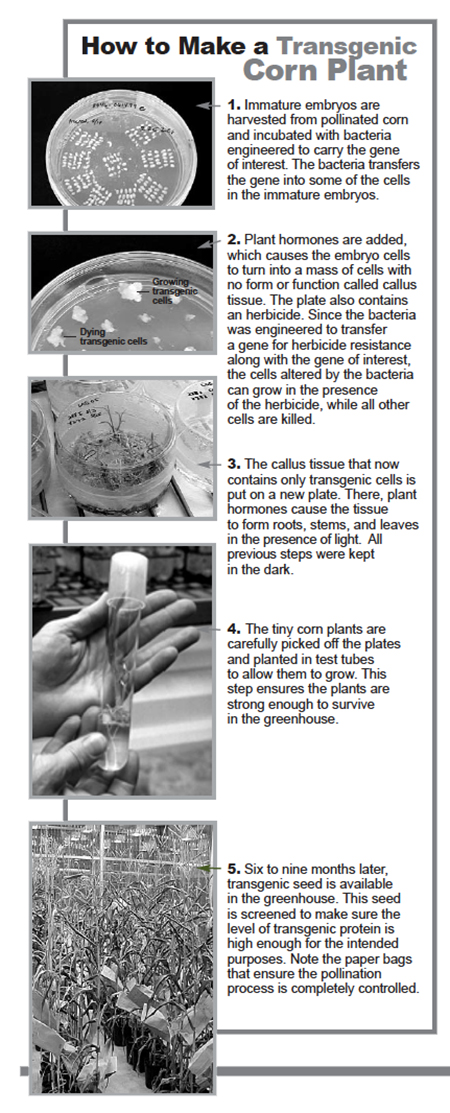

Transgenic plants and protein expression

With improved technology in the past decade, transgenic plants have been successfully used to express a variety of proteins. In 1999, over 60 million acres of transgenic plants were grown, indicating that the system of production of transgenic plants is stable and robust.

Many additional proteins have been expressed in plants solely for their antigenic potential, including viral proteins and subunits of bacterial toxins. Animal and human immunization studies have demonstrated the effectiveness of many of these plant-derived recombinant antigens in stimulating the immune system. In fact, ProdiGene, a biotechnology company based in Texas, USA, recently demonstrated a corn vaccine for swine that, when fed to the swine, protected them from infection by the transmissible gastroenteritis virus.

Benefits for vaccine production

The utilization of transgenic plants for vaccine production has a number of potential benefits over traditional vaccines in aquaculture disease management:

- Direct feeding is possible, since the vaccines are expressed in corn, significantly reducing labor costs and stress on the fish.

- Since there are no known human or animal diseases that are able to infect plants, concerns with contamination are eliminated.

- Vaccine production in transgenic crops relies on the same technologies established to sow, harvest, store, transport, and process the corn as those already used for feed crops, making corn a very economical means of large-scale vaccine production.

- Expression of the vaccine in the seed, which is the plant’s natural protein-storage compartment, maximizes the stability of the vaccine. This in turn minimizes the need for refrigeration and keeps transportation and storage costs low.

- Multivalent vaccines are possible by either blending the seed of transgenic corn lines containing other vaccines into a single multivalent vaccine, or expressing multiple antigens in the same plant. These edible vaccines could be used in a stand-alone vaccination strategy, as a booster, or in combination with other vaccines and vaccination routes.

Mucosal immune response

One of the most promising aspects of edible vaccines is the ability of orally administered antigens to stimulate a mucosal immune response. Mucosal surfaces – the linings of the respiratory, gastrointestinal, and urogenital tracts – play an important physical and chemical role in protecting animals’ bodies from invading pathogens and harmful molecules. Since most invading pathogens first encounter one or more of the mucosal surfaces, stimulation of the mucosal immune system is often the best first defense against many transmissible diseases.

Development of edible vaccines

ProdiGene is in the process of developing a number of edible vaccines in both the human and animal health areas. In particular, corn expressing viral proteins of swine transmissible gastroenteritis, an important swine disease, is currently being used in swine feeding trials. Preliminary data indicate that these vaccines protect the animals from viral infection.

Hybrid seed production

Once an inbred seed line is developed that contains the vaccine of interest, hybrid seed is produced that incorporates the necessary agronomic qualities needed for the area of production. ProdiGene has a partnership with Stauffer Seed of Aurora, Nebraska, USA, which produces the seed for ProdiGene and implements the grain production program.

Stauffer also performs other tasks, such as warehousing, inventory, and delivery of seed to the contract grower. It also implements grower contracts that specify production practices and quality-control measures, and provides agronomic support to producers for maximizing the yield and quality of the grain.

Optimizing production

ProdiGene and Stauffer work together to plan grain production by selecting the best growing areas, and identifying farmers capable of producing high-quality grain and ensuring identity preservation of the grain. Proper measures for isolation from neighboring crops are specified and documented. Approved production practices, including pesticide and fertilizer applications, are recommended and documented.

Trained agronomists work with the growers to help with best management practices and scheduling of grain delivery. At harvest, equipment and storage facilities are cleaned and the grain is assigned lot identification numbers for tracking through processing. Production records and management practices are recorded for future documentation.

Regulatory compliance

Grain processing and seed fractionation are currently done as toll processing at existing mills. Good Manufacturing Practices (GMP) are used in compliance with the established regulatory guidelines for processing identity- preserved grains and ProdiGene’s own quality assurance guidelines. The GMP practices include cleaning equipment with compressed air or vacuum, weighing and analyzing the incoming bulk material and existing fractions, labeling, inspecting the integrity of packaging, and preparing procedures for storage and shipment of fractions to another site for further processing if needed. Additional processing may involve oil removal, protein extraction, protein purification, or other operations.

Conclusion

Edible vaccines for aquaculture will be easy to administer by simply incorporating the expressed vaccine in grain in feed. These vaccines have the potential to eliminate much of the labor involved in current aquaculture health management strategies, reduce the stress of vaccination on fish, and open up new strategies for aquaculture health management.

(Editor’s Note: This article was originally published in the October 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Joe Jilka, Ph.D.

Vice President of Development

ProdiGene

101 Gateway Blvd.

College Station, TX 77845 USA

Tagged With

Related Posts

Health & Welfare

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

A study demonstrated that VP19 and VP28 white spot syndrome virus envelope proteins expressed by replicon particles provided protection against mortality due to WSSV in shrimp.

Health & Welfare

Antigens provide immunity against ich in channel catfish trials

Vaccination against the Ich parasite is an alternative to chemical treatment. Fish develop a humoral immune response to trophont antigens, with the degree of protection related to the immunizing doses of trophonts used.

Health & Welfare

Aquaculture viruses: An Atlantic salmon case study

Viruses often are the most potentially damaging pathogens in nature, affecting both wild stocks and farmed animals. Due to an Infectious Haematopoietic Necrosis (IHN) viral outbreak that occurred in Atlantic salmon in British Columbia, Canada some years ago, a vaccine for IHN was developed against this serious threat.

Health & Welfare

Chem-free fixes emerging in sea lice saga

Salmon farmers, using emerging technologies, are exploring new methods of sea lice mitigation in an effort to overcome one of the industry’s most persistent problems. New chemical-free innovations show an industry eager to adapt and adopt environmentally safe practices.