Improved knowledge of closed-systems, innovations in aquafeeds

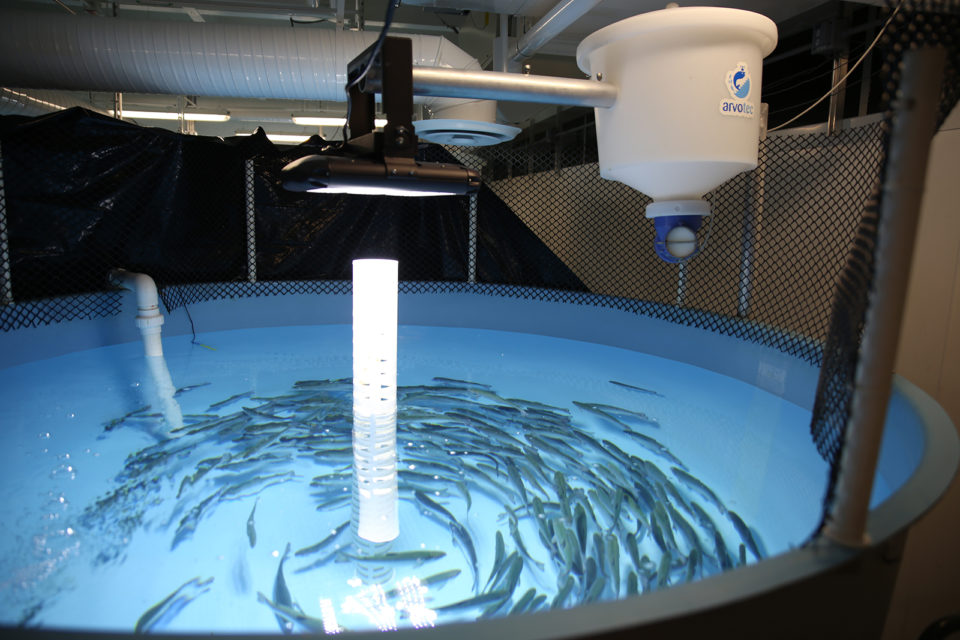

The first half of the second day of the conference highlighted research efforts to improve our understanding of trout and salmon production in closed-containment systems. (Read part 1 of this article.)

- Colin Brauner of the University of British Columbia described research on the effects of photoperiod and salinity (2.5, 5, 10 and 30 ppt) on Atlantic salmon and coho salmon growth and maturation over a 300-day growth trial. He noted that photoperiod had a large effect on Atlantic salmon growth and sexual maturation. In particular, a 12:12 (light:dark) photoperiod reduced growth by 15 to 20 percent compared to continuous light, even though feeding in all fish was restricted to 1 percent body weight per day.However, the 12:12 photoperiod virtually eliminated early maturation which was about 30 percent in continuous light, a finding that was independent of body size. Up to day 120, 10 ppt significantly increased growth in Atlantic salmon; however, in general, photoperiod had a greater effect than salinity throughout the growth trial.

- Lill-Heidi Johansen of Nofima (Norway) described the many projects covered by CtrlAQUA, particularly in the department of fish health. Nofima is host institution to CtrlAQUA. The overall objective of the CtrlAQUA program is to develop and refine environmental and husbandry parameters for optimized production of post-smolt Atlantic salmon in closed-containment systems, either in land-based RAS or floating systems. CtrlAQUA has been funded at 200 million NOK ($24 million) by the Research Council of Norway and industry user partners from 2015 to 2023.Projects are focused on optimizing post smolt production in both floating and land-based closed containment systems. Lill-Heidi reported that there are now 23 types of floating closed containment systems under development in Norway. And, in 2017, CtrlAQUA supported 14 projects divided between three departments. One of the major focuses is to improve how to sense, limit and control the environment used for post-smolt culture. Another focus of CtrlAQUA is to support the development of new talent, which includes a goal of 15 new Ph.D. graduates.

https://www.aquaculturealliance.org/advocate/closed-containment-technologies-salmonids-part-1/

- Sigurd Handeland of UNI Research (Norway) presented on a CtrlAQUA project that studied post-smolt production in three commercial-scale closed containment systems, i.e., Preline, Neptune and Eco Cage. All three systems were deployed at sea to culture Atlantic salmon from 100 grams to approximately 1,000 grams; salmon smolt were transferred to sea in late autumn. All three studies found that closed containment systems produced equal or better growth and feed conversion than in an open pen experimental control. Accumulated mortality was also very low, at less than 2.5 percent, in the three studies.Sea lice levels were also low in all three closed-containment systems. Fish were exercised in the flow within each closed containment system, which resulted in a 3.8 times higher frequency of small muscle fibers at the end of the post-smolt phase in trained group and might produce better growth later. Results from the fish health screening program also showed higher frequency of Pox virus, ISAV virus and more amoeba (Paramoeba perurans) in fish cultured in the open systems compared to the closed containment systems.

- Jelena Kolarevic of Nofima (Norway) reported on two additional CtrlAQUA studies with floating closed containment systems, i.e., Flexi Bag and Concrete Tank. No lice were observed in examined semi-closed-containment systems. Water quality in both systems was within current recommendations and water velocity conditions in the concrete tank offered good training conditions for post-smolts. Overall results on survival and performance were satisfactory. However, on two occasions in the Flexi Bag, amoebic gill disease and jellyfish caused mortalities. Jelena also noted that the recent Price Waterhouse Coopers report estimates that Norway has the potential to produce 3.5 million tons per year by year 2050, which includes 1 million ton of land-based production.

- Trine Ytrestoyl of Nofima (Norway) reported on a CtrlAQUA study where Atlantic salmon post-smolt were reared to 200 grams or 600 grams, in freshwater or 12 ppt brackish water, and at either 12:12 (light:dark) or 24-hour photoperiods. They found that 24-hour light and 12 ppt slightly improved growth in post smolt raised in RAS at up to 600 g. However, there were no effects of photoperiod or salinity on survival after sea water transfer with 600 grams post-smolt. There were no effects of treatment on male maturation. Smolt stocked at sea at 100 grams grew to a larger size than post-smolt stocked at 200 or 600 grams at sea. There was no effect of salinity or light treatment in the RAS on overall growth of the fish from 30 to 3,000 grams.

- Vasco Mota of Nofima (Norway) reported that although increase in carbon dioxide levels had no effect on eye cataracts, fish welfare scores, or nephrocalcinosis, they did find that increasing carbon dioxide levels linearly decrease growth of Atlantic salmon post-smolt when cultured at a salinity of 12 ppt at 13 degrees-C. This CtrlAQUA research is providing valuable water quality guidance to limit the impacts of dissolved carbon dioxide on post-smolt Atlantic salmon cultured in closed-containment systems.

- Yonathan Zohar of the Institute of Marine and Environmental Technology at the University of Maryland Baltimore County reported on progress to develop a non-GMO approach for creating sterile fish. The Wong and Zohar (2015) technique relies on disrupting the migration of the primordial germ cells, which occurs during early embryonic development, to the gonadal ridge, ultimately leading to gonads that have no germ cells and to reproductively sterile fish. The technology is based on short term immersion of the eggs or embryos, before or at fertilization, to compounds that specifically prevent the targeted migration of primordial germ cells.Yoni described the most recent studies on zebra fish, rainbow trout, and Atlantic salmon. He noted that developing a reliable process to produce sterile Atlantic salmon and rainbow trout is critical to avoid early sexual maturation and potentially improve overall population growth, feed conversion, and fillet yields, which will all help to increase production efficiency domestically and globally. In addition, farming infertile fish is the most effective genetic-containment strategy, to prevent fish escaping from farming operations to propagate or interbreed with wild stocks, thus supporting the development of environmentally responsible aquaculture.

- Astrid Buran Holan, formerly of Nofima (Norway), reported on disinfection of sea water intake flows using ozone, ultraviolet irradiation, microscreen filtration or advanced oxidation. This CtrlAQUA research characterized water filtration and disinfection technologies to exclude or inactivate pathogens and parasites in ocean water before entering closed containment systems.

- Chris Good provided a summary of the PHOTO research study carried out at The Conservation Fund Freshwater Institute in collaboration with scientists from Nofima, University of Bergen, and UNI Research (Norway) through the CtrlAQUA multi-year research initiative. The PHOTO study was conducted to evaluate different photoperiod and feeding regimes and their effects on performance, health, osmoregulation and maturation of Atlantic salmon post-smolts in freshwater aquaculture systems, up to 1,000 grams in size.Thus far, the best performing post-smolts have been those provided with constant (i.e., 24-hour) photoperiod and a 100 percent feeding regime; however, results of the majority of laboratory analyses are forthcoming, and the longer-term effects of both natural photoperiod and reduced (60 percent) feeding regime will be assessed as the salmon grow to market size in 2018.

- John Davidson presented findings that suggest that continuous peracetic acid (PAA) dosing in RAS does not result in dramatic water quality improvements like those provided by low-dose ozonation. Peracetic acid dosing did not negatively affect nitrification or rainbow trout health and performance. The authors found that increasing oxidative reduction potential (ORP) was associated with peracetic acid dosing, suggesting that ORP could be used to monitor and control PAA residuals in fish production systems.

- I presented findings from two studies that examined the performance of all-female Atlantic salmon when cultured to market-size in freshwater closed-containment systems at The Conservation Fund Freshwater Institute. Salmon sampled for gonadal size in the first study, conducted from 2009 to 2010 and supported by the USDA ARS, found no female maturation when two strains of Atlantic salmon (one an all-female strain and the other a mixed-sex strain) were cultured at approximately 13 degrees-C in a freshwater reuse system to market size (4 kg).The second study conducted in 2016 to 2017, however, found high levels of female maturation in an all-female germplasm; a retrospective assessment suggested that these fish might have accidentally received a second winter photoperiod cue as post-smolts when cultured under continuous light, leading to increased maturation during grow-out. This hypothesis, however, remains unproven.

Feed innovations

The afternoon included two presentations on innovations in fish feed.

- Roar Sandvik of Skretting (Norway) presented on their work to optimize Atlantic salmon and trout feeds for closed-containment systems. He said that feed ingredients are chosen to provide high digestibility, nutrient bioavailability and fish growth, as well as by cost. He noted that, in North America, it is relatively easy to source many of the ingredients locally and that North America also has a wider range of ingredient choices because certain animal proteins and fats are allowed in fish feeds in North America but not in Europe. He said that Skretting is applying high quality guar gum as necessary to produce more stable fecal pellets, but that blood meal can also improve fecal stability.Sandvik concluded by showing a new research laboratory that Skretting just opened in Lerang (Norway) that provides twelve experimental RAS systems, each with 1.5-cubic-meter tanks. He said that the facility will allow assessment of new diets to help assure performance factors such as growth, FCR, water quality, diet digestibility and fecal pellet stability are maintained to support future success in RAS systems.

- Jason Mann of Evaqua (Idaho) highlighted a farmer’s perspective on feed ingredients. He encouraged more fish farmers to insist that the feed supplier use only high-quality ingredients. Oils, for example, must be sourced that have low oxidation and high digestibility. He also noted that care must be taken to ensure that beans and lentils do not deliver too many anti-nutritional components that can create enteritis in the fish and/or unstable fecal pellets. He suggested that there was tremendous promise using North America-sourced ingredients and that new protein and omega-3 fatty acid sources were being developed that would be more competitive with fishmeal and fish oil prices.Fish farmers want and request fish feeds which are consistent and made from high-quality ingredients. At times, there may be a temptation to source lower costing feed ingredients that might compromise fish performance, fecal stability or the nutritional content (e.g., omega-3 fatty acid content) of the fillets produced. An open dialogue between the fish farmer and the feed supplier is very important as seafood consumers are asking for more transparency about what the farmed fish was fed.

The AIW concluded with three presentations from industry suppliers that are challenging the status quo with innovations in RAS design and waste management. K.C. Hosler from Pentair (British Columbia) and Frederic Gaumet from Krüger Kaldnes Veolia (Norway) presented on progressive improvements in salmon RAS design.

As an engineer, I really appreciated the design logic that KC Hosler described, as he has optimized water treatment technologies and their integration within salmon RAS over the last decade. I also appreciated the scale and continuity of projects that Krüger Kaldnes Veolia has undertaken. Frederic Gaumet presented first data from the RAS 2020 pilot plant in Switzerland, as well as Veolia plans and actions to develop through digitalization a proactive and integrated tool for RAS daily operation and management. Lars Rohold of Scanship AS (Norway) presented on biosolids dewatering and drying methods being applied at several of the large RAS facilities producing smolt and post-smolt in Norway. Lars pointed out the potential of creating value out of the biosolids coming from fish farming.

Videos of the presentations and/or Adobe PDF files of the PowerPoint presentations are available on the AIW webpage for most presentations, i.e., when the authors have granted permission.

Concluding remarks

We have organized and convened nine AIWs; all have focused on communicating the biological, technical, economic and marketing opportunities and challenges surrounding salmonid production in closed-containment systems, but especially in land-based RAS.

Since the first AIW was held in 2011, a key reason for the success of these AIW has been the open dialogue and willingness to share information on emerging RAS technologies among those that might otherwise be considered competitors, i.e., commercial producers, suppliers and consultants. We have all benefited when the early adopters have shared lessons learned while engineering and building their facilities.

These pioneers of industry (such as Kuterra, Langsand Laks, Billund, Veolia, Pentair and others) have graciously shared their efforts to innovate and challenge the status quo. In addition, the massive investment in RAS to produce salmon smolt and post-smolt in Norway (and globally) has also helped improve the technology and train the staff that are often hired to work in RAS for salmon and trout grow out to market size.

Increased investment in salmonid RAS (whether for smolt/post-smolt or market-size fish) is accelerating its deployment, which has ultimately led to reductions in capital and operating costs due to improvements in technology, standardization in equipment and construction methods and economies of scale.

It’s personally gratifying to see that a major take-home message from the AIW was that the existing industry, along with financial institutions and entrepreneurs, are becoming more engaged in the adoption of RAS to increase production of Atlantic salmon. This is a huge change from 2011, when few people outside of our group felt that RAS would be biologically, technically and economically viable systems for producing market-size Atlantic salmon. Until just two years ago, it seemed like change was happening very slowly, at least in the United States, where government typically won’t subsidize the startup investment in contrast with European Union practices. However, change is now happening much more rapidly and it appears to be accelerating with the attention of major salmon farming producers, major equipment supply companies, financial institutions and other investors.

Businesses for producing land-raised Atlantic salmon are already established in Europe and Canada but are just starting in the United States. As noted above, Superior Fresh LLC in Wisconsin will be the first U.S. commercial producer to put land-raised Atlantic salmon into the market this summer. In addition, Atlantic Sapphire is currently building a large “blue house” to produce market-size Atlantic salmon in Florida. And, Nordic Aquafarms and Whole Oceans have announced their intentions of launching two large land-based Atlantic salmon farms in Maine. There are several additional projects that haven’t gone public yet, but these will likely push the total U.S. investment towards $500 million in just a few years.

The US East Coast appears to be a nexus for these projects, but projects are in the works at locations across the country. It’s still uncertain which of these projects in development will finalize their financing; financing appears to be the largest challenge for most of the project proponents. Their ultimate economic success will depend on many factors, including the reliability of their technology, the effectiveness of their staff and staff training programs, their ability to develop a brand during marketing, the future salmon market, the future strength of the U.S. dollar, and other issues surrounding their business plan.

The research and development that has been presented at AIW has provided essential support to the new producers, system suppliers, and consultants that work with RAS technologies; it has helped to improve both the biological and technical reliability of these production systems while reducing risk.

Thanks to the foresight of groups such as U.S. Department of Agriculture’s Agricultural Research Service and the Research Council of Norway (CtrlAQUA more recently; RASALMO previously), who have supported this ground-breaking effort to develop RAS for salmon and trout even before the existing industry suspected that these production systems would be required.

This research and development, often presented at the AIW, is now paying off with business investment in many commercial production systems, as well as in the photoperiods applied, bio-plans adopted, germplasm selected, biosecurity practices and processes for carbon dioxide removal implemented, ozonation, solids control, biofiltration, culture tank hydrodynamics and finishing/purging.

That said, the technology is still advancing and evolving. As an example, the interactions between ingredient inclusion within feed formulations, fish performance, and resulting water quality are of paramount importance in RAS, which requires continued work.

The AIW continues to be a catalytic meeting that brings together a community of diverse stakeholders to create a focused communication space critical for increasing the adoption of closed-containment systems. As a collective group, we are helping to establish the technologies and procedures required to increase finfish production in a manner that is more environmentally friendly and economically sustainable. These events have provided an important opportunity to share innovations and lessons learned and continue an ongoing conversation about the direction of the industry.

We are still looking for a location for the 10th AIW, which will likely be held in late November or early December of 2018, probably on the east coast of the United States. There are a number of new closed-containment projects that we hope to include in the 2018 AIW program, as well as more research on the biological and technical aspects of these new technologies. If you are interested in participating, keep an eye out for the meeting on our website, which was listed earlier in the article.

Author

-

Steven Summerfelt, Ph.D.

The Conservation Fund Freshwater Institute

1098 Turner Road

Shepherdstown, WV 25443 USA

Tagged With

Related Posts

Innovation & Investment

Developments in closed-containment technologies for salmonids, part 1

The recent 2017 Aquaculture Innovation Workshop in Vancouver brought together numerous stakeholders involved in and interested in fish farming – particularly salmonids – in the growing industry of closed-containment systems.

Innovation & Investment

Competitiveness comes at scale for RAS operations

Total RAS salmon production worldwide is less than half of 1 percent of total production. Many of the investors flocking to the sector now are new to fish farming, and confident in its potential.

Innovation & Investment

Getting proficient in RAS fundamentals

A number of large salmon farming companies are now investing significantly to increase land-based, water recirculating aquaculture systems (RAS) in northern Europe and North America, and there is likely a need for more trained farm personnel to run and manage these and other close-containment aquaculture facilities.

Health & Welfare

Novel air-based system transfers large salmon during harvest

To evaluate the application of an air pressure-based transport method within a recirculating aquaculture system, the authors performed testing with harvest-size salmon at The Conservation Fund Freshwater Institute.