Ingredient bottleneck a potential roadblock for shrimp farmers

Cholesterol is an essential nutrient for penaeid shrimp. It is a key constituent of cell membranes and a precursor for steroid and molting hormones. Fluctuations in the availability and price of the main sources of cholesterol for shrimp feed – marine ingredients and feed-grade cholesterol – are a serious concern for shrimp feed formulators.

Cholesterol bottleneck

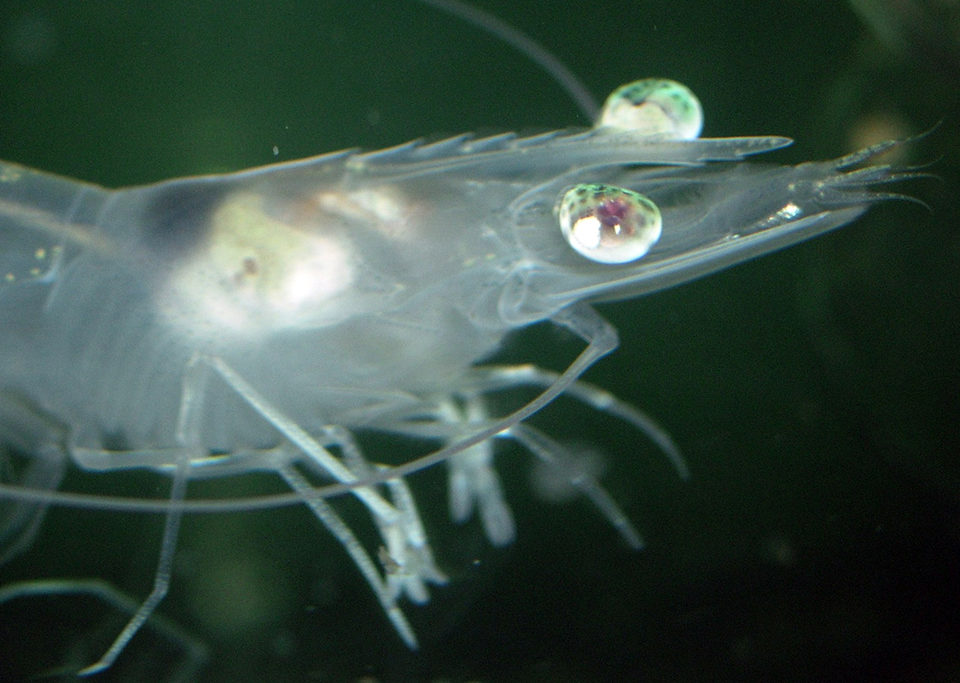

Shrimp have no or very limited capacity to biosynthesize a number of lipid molecules essential for normal growth, including cholesterol, highly unsaturated fatty acids and phospholipids. Published cholesterol requirements for different species of shrimp range from 0.25 to 0.50 percent. Cholesterol levels below 0.10 percent limit growth in Litopenaeus vannamei, even if the other nutrients are formulated to satisfy normal requirements.

All protein meals and fats from animal origins contain cholesterol, but ingredients from marine sources – including fishmeal, fish oil, squid meal and shrimp meal – are particularly rich sources. With its 0.25 to 0.35 percent cholesterol content, fishmeal is often the major cholesterol source in practical feed formulations for shrimp.

Sharp price increases for fishmeal and fish oil have resulted in the significant replacement of these ingredients with fats and proteins of vegetable and terrestrial animal origins that have limited levels and availability of cholesterol. As a result, it has become increasingly difficult to maintain adequate levels of available cholesterol in shrimp feed formulations. Supplementation of purified cholesterol is often needed to fully cover the requirement.

Cholesterol is purified from wool grease (lanolin), a byproduct collected during the washing of sheep wool. The cost and availability of feed-grade cholesterol fluctuates with the variations in global supply and quality of wool grease.

Diminishing sheep stocks and increasing competition for lanolin derivatives (e.g., to synthesize steroids) have become serious concerns. Feed volumes required by the shrimp industry are expected to keep growing, whereas fishmeal levels will continue to be reduced.

Digestibility enhancers

Lipid digestion in shrimp is largely an intracellular process in the hepatopancreas epithelium, from which lipids are transported to the target organs via the haemolymph as lipoproteins. The formation and absorption of lipid micelles from the lumen of the hepatopancreas tubuli is therefore a limiting step in the lipid digestive process.

Digestibility enhancers based on natural emulsifying agents selected for their compatibility with shrimp digestive systems have proven capable of complementing the process of emulsification, increasing the efficacy of the lipase activity and absorption of dietary fats in the hepatopancreas. This, in turn, improves the ability of shrimp to efficiently use fats as essential components and sources of energy for growth.

Cholesterol replacement trials

Two trials were set up by the authors to evaluate if the use of a digestibility enhancer based on natural emulsifiers could reduce the need for cholesterol supplementation in the diet of black tiger shrimp (Penaeus monodon). Experimental pelleted diets were formulated to satisfy the nutritional requirements of P. mono-don, except for cholesterol.

Three diet formulations were used: a control diet with no cholesterol supplementation and a background concentration of 0.10 percent cholesterol provided by fishmeal and shrimp head meal (CON), a positive control diet supplemented with 0.15 percent cholesterol to a level of 0.25 percent cholesterol in the diet (CON+) and a test diet supplemented with Aquagest S, a commercial digestibility enhancer based on an optimized blend of natural emulsifiers (TEST).

To verify initial findings, a second trial was run using different batches of raw materials. This resulted in slightly different proportions of fishmeal (35 percent) and defatted soybean meal (25 percent), and a higher background of cholesterol in the feeds. In trial 2, CON, CON+ and TEST contained 0.15, 0.30, and 0.15 percent cholesterol, respectively.

The experimental setup consisted of nine cylindrical, 1-metric-ton, flat-bottom tanks. Seawater was prepared by pumping it through a 1-µ filter bag and recirculating it over a 1.6-metric-ton coral biofilter. Salinity was adjusted to 25 ppt by the addition of underground freshwater, and 3 mg/L hypochlorite powder was applied for 24 hours for disinfection.

Mean water renewal over the whole culture period was 28 percent/day. Shrimp of 0.3-gram to 0.4-gram weight were initially stocked at 20 shrimp/tank and acclimated for one week prior to the start of the trial. Water temperature (27.5 ± 0.7 degrees-C), salinity and other quality parameters remained within acceptable limits during the tests.

Results

In trial 1, overall shrimp growth of up to 1.4 grams/week and survival close to 90 percent were excellent under the conditions of clearwater culture. Growth and feed conversion were significantly improved by the supplementation of 0.15 percent cholesterol. After 70 days of culture, harvested biomass was 33 percent higher for the shrimp fed the diet supplemented with cholesterol (Table 1).

Coutteau, Growth performance of black tiger shrimp, Table 1

| CON (0.10% cholesterol) | CON+(0.25% cholesterol) | TEST (0.10% cholesterol + enhancer) |

|---|

CON (0.10% cholesterol) | CON+(0.25% cholesterol) | TEST (0.10% cholesterol + enhancer) | |

|---|---|---|---|

| Survival (%) | 88.3 ± 5.8 | 90.0 ± 5.0 | 91.7 ± 7.6 |

| Initial weight (g) | 0.65 ± 0.04 | 0.64 ± 0.02 | 0.66 ± 0.02 |

| Final weight (g) | 5.90 ± 0.40a | 7.80 ± 0.40b | 7.50 ± 0.20b |

| Final biomass (g) | 103.00 ± 2.00a | 137.00 ± 9.00b | 134.00 ± 8.00b |

| Feed-conversion ratio | 3.9 ± 0.2a | 3.1 ± 0.2b | 3.4 ± 0.1b |

The digestibility enhancer was as effective as the purified cholesterol in improving growth and feed conversion. After 70 days of culture, harvested biomass was 30 percent higher in the TEST treatment compared to the negative control.

Overall shrimp survival was lower in trial 2, averaging 77 to 85 percent. However, the trends in growth response observed in this independent trial – run with different shrimp and different batches of raw materials for feed preparation – generally matched those of the first trial (Figure 1).

White shrimp study

By improving the utilization efficiency of dietary lipids, shrimp formulations can be made more cost-effective by reducing the formulated values for phospholipids, cholesterol and n-3 highly unsaturated fatty acids (HUFAs). The compensation of lower dietary specifications for essential lipids by the application of a digestibility enhancer was demonstrated in a nutritional trial in Indonesia with white shrimp.

The partial replacement of traditional sources of phospholipids, purified cholesterol and n-3 HUFAs (including fishmeal, fish oil, purified cholesterol, soybean lecithin and squid meal) resulted in improved growth performance and reduced the dependency of formulation costs on bottleneck ingredients (trial 3: Tables 2 and 3).

Coutteau, Feed formulations for traditional feed and novel feed, Table 2

| Traditional Feed | Novel Feed | Difference |

|---|

Traditional Feed | Novel Feed | Difference | |

|---|---|---|---|

| Crude protein (%) | 35.80 | 34.80 | -3% |

| Crude fat (%) | 8.70 | 8.20 | -6% |

| Crude ash (%) | 9.10 | 9.40 | +4% |

| Moisture (%) | 9.59 | 9.64 | +1% |

| Watersol phosphorous (%) | 0.48 | 0.32 | -34% |

| Cholesterol (%) | 0.18 | 0.10 | -44% |

| Phospholipids (%) | 0.93 | 0.85 | -9% |

| EPA (mg/g dry matter) | 4.8 | 5.0 | +4% |

| DHA (mg/g dry matter) | 5.7 | 4.8 | -16% |

| n-3 HUFA (mg/g dry matter) | 11.9 | 11.1 | -7% |

Coutteau, Growth performance of white shrimp fed experimental feeds, Table 3

| Traditional Feed | Novel Feed | Difference |

|---|

Traditional Feed | Novel Feed | Difference | |

|---|---|---|---|

| Survival (%) | 91.7 | 93.3 | +2% |

| Initial weight (g) | 1.02 | 1.02 | – |

| Final weight (g) | 11.31 | 12.74 | +13%* |

| Growth (g/week) | 1.03 | 1.17 | +14%* |

| Feed-conversion ratio | 2.29 | 2.31 | – |

(Editor’s Note: This article was originally published in the September/October 2011 print edition of the Global Aquaculture Advocate.)

Authors

-

Peter Coutteau, Ph.D.

Nutriad International NV

Schietstandlaan 2

2300 Turnhout, Belgium -

Sam Ceulemans

Nutriad International NV

Schietstandlaan 2

2300 Turnhout, Belgium -

Alexander van Halteren

Nutriad International NV

Schietstandlaan 2

2300 Turnhout, Belgium

Tagged With

Related Posts

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

Algae alternative: Chlorella studied as protein source in tilapia feeds

Chlorella and other species have potential as protein sources in aquafeeds. In trials with tilapia fry raised in a recirculating system, the fish received a fishmeal-based control diet or feeds with portions of the fishmeal replaced by Chlorella.