Determining strain may identify place of origin or exclude certain producers

Both aquaculture and capture fisheries are coming under increasing pressure from consumers and governments to implement measures such as traceability and improved quality testing. New certifications and initiatives are quickly gaining momentum.

These measures are indeed vital, but do not address one fundamental problem that has plagued the industry for years: the accidental or deliberate mislabeling of products to hide their origin or disguise their true nature.

Recent high-profile cases include the mislabeling of fish sold in supermarkets in the United States, most notably cheap whitefish sold as more expensive marine species like red snapper. For the tilapia market, statistics indicate the amount of “fresh” fillets sold in the U.S. is almost double the amount of fresh fillets actually imported into the country.

Branding efforts undermined

The problem of mislabeling is not a trivial issue, but rather one that must be addressed by any company seeking to establish a strong brand. Why spend significant time and funds to build a brand with all the right certifications if that brand cannot be protected?

Norwegian salmon producers learned that branding is not enough. They made a costly effort to establish a strong position in China only to find that some producers are now selling other salmon as Norwegian. If consumers learn that much of the supposedly fresh tilapia fillets sold in the U.S. were previously frozen, they may not be willing to pay higher prices.

DNA solution

Proving from where a product comes or exposing false products may seem daunting, but one key to the solution is DNA, carried in the cells of all living organisms. DNA technology, for example, has been used to establish reliable information on populations of wild fish.

Within a certain fishery or ecosystem, different types or strains of the same species are usually present. Although the physical appearance of the fish is very similar, they may in fact have genetic differences and different social behavior, usually the result of physical separation for thousands of years. By analyzing DNA collected from wild stocks in different geographical areas, it is possible to establish the boundaries of such separated populations and identify where a fish was originally caught.

Similar techology can also be applied within the farmed seafood value chain, because it is capable of distinguishing between farmed products of different animal strains. In cases where one particular animal strain is utilized by only a handful of farmers, determining the strain may give detailed information about the place of origin or at least exclude a majority of producers.

Aquaculture product verification

Product samples are tiny and can be collected without impacting the quality of sampled products. Even live animals can be sampled without causing harm. Sampled products must contain at least some preserved DNA from the original farmed animals, so DNA testing may exclude items like fermented, cooked and fried products.

In DNA testing, genetic markers are applied to samples to establish their DNA profiles. The individual profiles can then be compared with those of other samples or stored profiles of other known fish or seafood tissues.

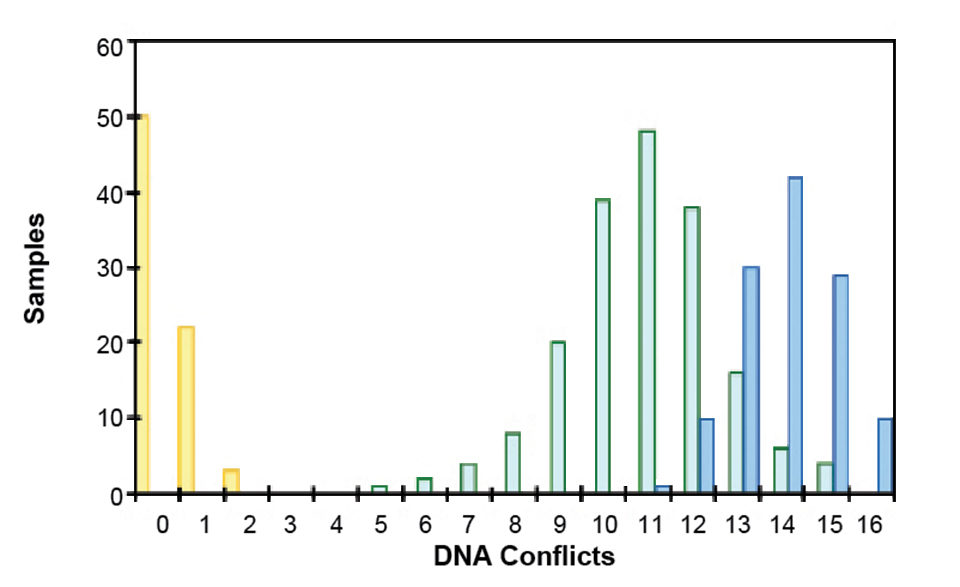

Fig. 1 shows how GenoMar’s patented GenTrack DNA verification system responds to a specific known tilapia product (yellow) and two genetically similar tilapia products from different value chains (green and blue). The green samples are from the same strain as the yellow product, while the blue samples are from a strain from a different country.

Since the GenTrack server is unable to match the DNA profiles of the green and blue products to that of the known tilapia, it indicates a number of conflicts and subsequent rejection of the foreign samples. The blue samples match the least because they are from a different strain.

Implementation

Implementation of this type of verification requires certain basic criteria for the production cycles within an aquaculture company. Seedstock must originate from a known source, typically a broodstock pool selected for specific qualities. And the producer must have a functional traceability system – even a paper-based system will do.

After implementation, the system can identify with great certainty any fish, shrimp or processed product from a particular production line. Mislabeled or counterfeit products will stand out clearly and fail the verification test. Producers can provide physical proof that their supplied products are genuine. It also enables wholesale buyers to request verification of origin of the farmed products they are buying.

(Editor’s Note: This article was originally published in the March/April 2008 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Vidar Lund

GenoMar ASA

P.O. Box 1159

Sentrum, 0107 Oslo, Norway[109,111,99,46,114,97,109,111,110,101,103,64,114,97,100,105,118]

-

Prof. Øystein Lie

GenoMar ASA

P.O. Box 1159

Sentrum, 0107 Oslo, Norway -

Woo Jai Lee, Ph.D.

GenoMar ASA

P.O. Box 1159

Sentrum, 0107 Oslo, Norway

Tagged With

Related Posts

Intelligence

A brief look at genetically modified salmon

If approved by FDA, fast-growing genetically modified salmon will provide a safe and nutritious product similar to other farmed Atlantic salmon.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 1

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors investigated the problem holistically.

Health & Welfare

A study of Zoea-2 Syndrome in hatcheries in India, part 2

Indian shrimp hatcheries have experienced larval mortality in the zoea-2 stage, with molt deterioration and resulting in heavy mortality. Authors considered biotic and abiotic factors. Part 2 describes results of their study.