Trials evaluate the effect of different mesh sizes

Drum filters have been demonstrated to be efficient in several tests, although the effect of using different mesh sizes has not been clearly determined. An extensive investigations was carried out at DIFTA in a recirculated eel farm in Denmark, as part of a ”blue” label project supported by the Commission of the European Union (Fair CT-9158).

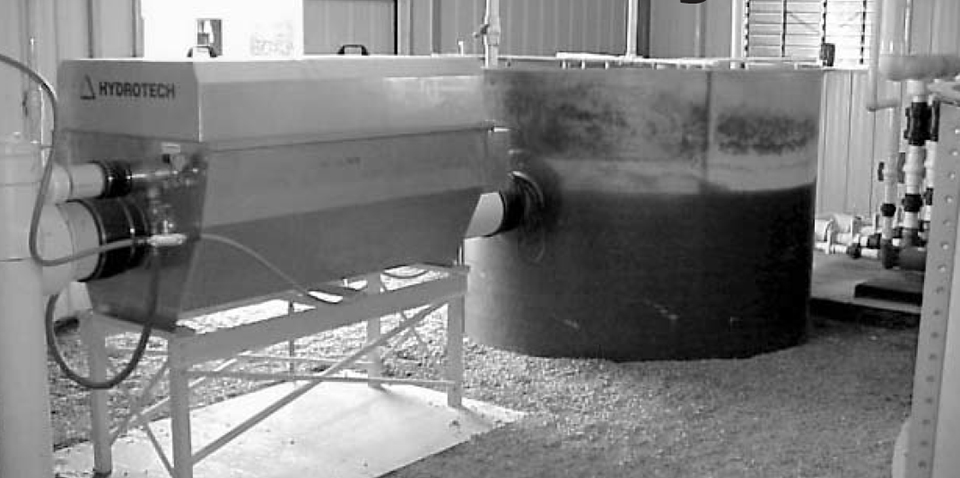

Experimental setup

The test system included 18 circular tanks, each 450 liters. The hydraulic load of the drum filter was 27 cubic meters per hectare (Hydrotech model HDF1201-1H), and it was directly connected to the fish tanks and two submerged biofilters combined with one trickling filter. Return flow was through oxygen cones. Three different mesh sizes (30, 60 and 100 microns) were tested for one month each. Filter performance was satisfactory during the entire test period. The drumfilters operated in a discontinous mode, in which drum rotation was actuated by a levelstick indicating headloss over the filter cloth. Filtered water was used to rinse the jet system, spraying the particles down into the sludge trough.

Results

As expected the relative water consumption, as well as the fraction of the recycled water used for spraying, decreased with increasing mesh size, from 200 to 50 liters per kg of feed, and from 0.23 to 0.06 percent of the internal flow (Table 1). Water exchange was satisfactory for a recirculated system.

Mortensen, Relative water consumption for the drumfilte, Table 1

| Mesh Size | 30 micron | 60 micron | 100 micron |

|---|

Mesh Size | 30 micron | 60 micron | 100 micron |

|---|---|---|---|

| Liter/kg feed | 200 | 100 | 50 |

| % of recycled water | 0.23 | 0.11 | 0.06 |

Mass balances for suspended solids, COD, nitrogen and phosphorous

Based on measures of internal flow, water consumption of the drum filter and the results of the chemical analyses on samples taken at the end of each test period, the mass balances for suspended solids, COD, nitrogen and phosphorous were determined for the three mesh sizes. Efficiencies were calculated using the energy equation, I = G + R +U + F, where I = feed intake; G = growth; R = respiration; U = Excretion; and F= feces. Efficiency is a measure of how large a fraction of the material in the feed (not used for growth or respiration by the fish) is recovered in the sludge from the drumfilter. Results are shown in Table 2.

All sludge materials were closely examined to evaluate the origin of particles contained. It should be emphasised that efficiency figures include suspended solids in the form of bacteria flocs from the biological filters, hence the values higher than 100 percent. At 30 microns, 25 percent of total suspended solids were accounted for by the bacterial floc fraction. The true efficiency of suspended solids removal can therefore be estimated to be approximately 75 percent.

Mortensen, Removal efficiencies of drumfilter, Table 2

| Mesh Size | Suspended Solids | COD | Nitrogen | Phosphorous |

|---|

Mesh Size | Suspended Solids | COD | Nitrogen | Phosphorous |

|---|---|---|---|---|

| 30 micron | 99% | 92% | 103% | 101% |

| 60 micron | 48% | 54% | 49% | 91% |

| 100 micron | 21% | 20% | 24% | 47% |

Conclusion

Aseries of trials were conducted to evaluate the effect of three different mesh sizes (30, 60, or 100 microns) on the efficiency of a drum filter. Water consumption varied between 0.06 percent (100 micron mesh screen) and 0.23 percent (30 micron mesh screen). Removal efficiency for suspended solids, COD, nitrogen, and phosphorus increased with decreasing mesh size. True efficiency of solids removal (excluding bacterial flocs from biofilters) for the 30 micron mesh was estimated to be approximately 75 percent.

(Editor’s Note: This article was originally published in the June 2000 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Innovation & Investment

Connecticut ‘urban fish farm’ leans on RAS to produce branzino

The Ideal Fish “urban fish farm” in Connecticut is producing branzino, or European sea bass, using RAS technology. Learn about this project from the company that designed and supported it: Pentair Aquatic Eco-Systems.

Responsibility

Geotextile bag, flocculant technology capture RAS waste

Geotextile bags used in combination with polymer flocculant aid chemicals can provide effective primary treatment of recirculating aquaculture system effluent. Much of the suspended solids that carry the majority of the organic load within the effluent can be captured by these systems.

Intelligence

Top eel farm upgrades effluent treatment in Netherlands

The largest eel farm in the Netherlands, Nijvis, invested in an expanded, state-of-the-art effluent treatment system.

Innovation & Investment

Unit processes in RAS systems

For most effective use, water should have low turbidity and high U.V. transmittance, with ultraviolet dosage tuned to the target organisms. Low-pressure/high-output amalgam U.V. lamps are often used in RAS systems.