High-energy electrons are accelerated to the speed of light by a linear accelerator

According to the U.S. Centers for Disease Control (CDC), 5,194 people in the United States die annually due to foodborne illnesses. There are an estimated 76 million cases that lead to 325,000 hospitalizations. Five pathogens account for over 90 percent of deaths: Salmonella, Listeria, Toxoplasma, Norwalk-like viruses, Campylobacter and Escherichia coli. The direct cost of foodborne illnesses has been estimated at $6.5 to $34.9 billion. However, the compromise of consumer confidence in the capability of the food industry to deliver safe foods is immeasurable.

Food irradiation and consumer acceptance

Electric power, radios, televisions, microwaves, and lights emit low-energy long-wavelength radiation that is sufficient to move molecules. Heat is generated due to the friction between the molecules exposed to these types of radiation. However, low-energy radiation cannot structurally change the atoms in molecules.

Ionizing radiation has higher energy that is sufficient to eject an electron that forms an ion. However, the energy of ionizing radiation is not sufficient to split atoms and cause exposed foods to become radioactive. Therefore, the sources of ionizing radiation allowed for food processing (cobalt-60, cesium-137, accelerated electrons, and x-rays) cannot make food radioactive.

The Joint Expert Committee on Food Irradiation representing the United Nations Food and Agriculture Organization, International Atomic Energy Agency, and World Health Organization concluded that irradiation of any food up to 10 kiloGrays causes no toxicological hazards and introduces no nutritional or microbiological problems.

Several research papers have been published regarding the consumer acceptance of irradiated foods. The initial low acceptance of irradiated foods has been shown to increase significantly as a function of consumer education. In fact, consumers start demanding irradiated foods as soon as they realize the food safety benefits of food irradiation and learn that reputable national and international scientific and governmental agencies encourage food irradiation.

Electron beams

Electron beams (e-beams) are one of the sources of ionizing radiation. In contrast to heat and high-pressure processing, e-beams utilize high-energy electrons accelerated to the speed of light by a linear accelerator for pasteurization or sterilization. Subsequently electrons penetrate treated products to inactivate bacteria.

Typically, the food products are placed on an input conveyor, processed by e-beam, and received at the output conveyor. Linear accelerators that deliver electrons from the top are commonly referred to as single-sided e-beam systems, as opposed to the double-sided machines that deliver electrons from two sides.

The source of electrons is electricity and, unlike gamma radiation, e-beam technology does not use radioisotopes. Therefore, e-beams are considered more safe and consumer-friendly. E-beam processing does not raise a product’s temperature and hence preserves the freshness status of the processed product. Therefore, e-beams can be particularly useful for processing fresh fish. E-beams are currently used on a commercial scale for several types of meat to reduce or eliminate microbial pathogens and extend shelf life.

The dose is the quantity of radiation energy absorbed by food as it passes through the radiation field during processing. Doses are generally measured in Grays (G) or kiloGrays (kGy). E-beams enable the application of much higher dose rates than gamma radiation, so processing time with e-beams is much shorter than with gamma radiation.

Regulatory status of food irradiation

The application of ionizing radiation has been approved for various foods. Fresh and frozen red meats are irradiated up to 4.5 and 7.0 kGy, respectively, to reduce Escherichia coli. Irradiation of poultry and poultry products at up to 3 kGy (fresh) and 7 kGy (frozen) is used to reduce Salmonella, Campylobacter and other foodborne pathogens. Dried herbs and spices are processed with up to 10 kGy to reduce pathogens. Radiation is also used to extend the shelf life of fruits and vegetables and as a quarantine measure for imported grains, fruits, and vegetables.

The National Fisheries Institute submitted a petition in 2000 to the U.S. Food and Drug Administration for approval of radiation for processing fish products. The petition has been accepted for review and currently has a pending status.

Electron penetration

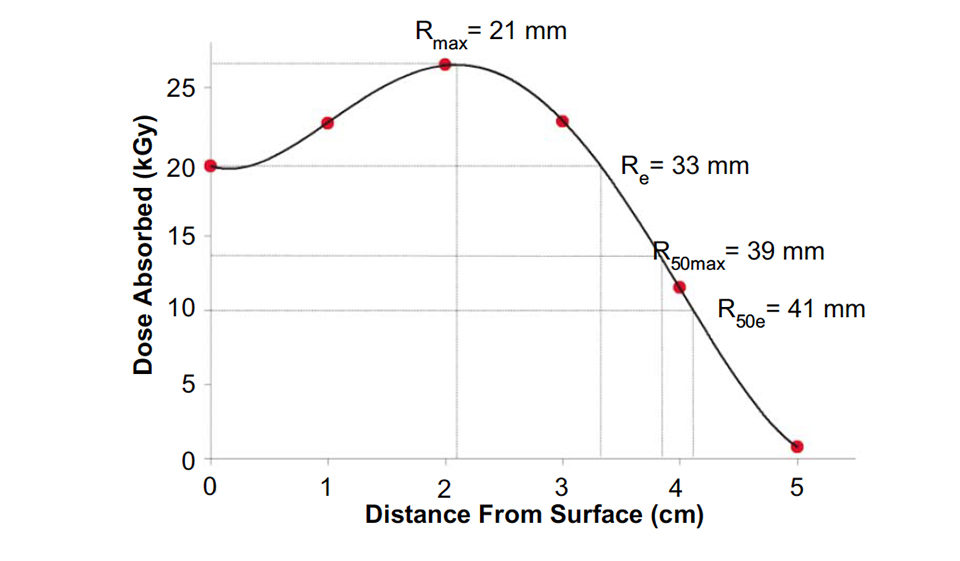

West Virginia University is examining the safety and quality of foods subjected to e-beams. Unlike gamma radiation and x-rays, e-beams have a limited penetration depth. Fig. 1 shows the electron penetration of a single-sided e-beam in a fish product. The “dose map” was developed using surimi gels in which dosimeters were inserted every 1 cm from the gel’s top surface to the bottom. Composed of purified fish muscle proteins obtained by the sequential washing of fish mince, surimi is used to manufacture seafood products like imitation crabmeat.

Regardless of the dose applied, absorption increases slightly under the surface up to 21 mm (Rmax), then gradually decreases to the depth of 33 mm (Re). No radiation is absorbed at a depth of 5 cm. The dose absorption reaches 50 percent of the dose applied at 41 mm (R50e).

The dose absorbed is additive. Therefore, the application of e-beams from two sides results in a uniform dose distribution in processed products as thick as 82 mm. If only a single-sided e-beam is available, an alternative approach is to turn the product over and process it again. If the product is too thick, certain areas of the product will be underprocessed, which may result in pathogen survival in those areas and subsequent recontamination of the product.

E. coli study

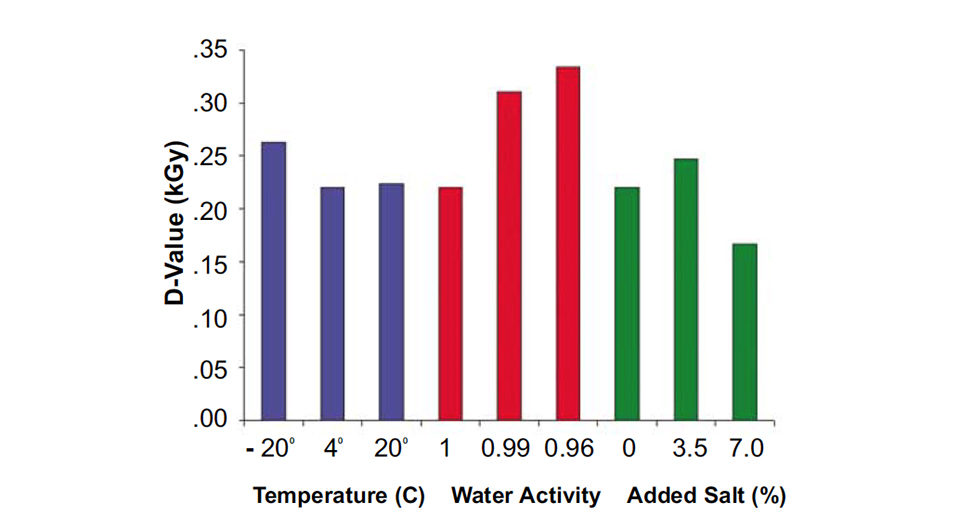

Research on the e-beam inactivation kinetics of the human foodborne pathogen E. coli O157:H7 in fish was conducted at West Virginia University. In such work, the D-value is commonly used as an indicator of bacterial survival after subjection to heat, high pressure, ionizing radiation, or other stressors. The D-value or decimal reduction is the dose in kiloGrays required to inactivate 1 log (90 percent) of the initial microbial population. A 90 percent reduction is generally considered insufficient. However, a typical goal in the canning industry is 12-D-value processing, which results in microbial reduction by 12 logs.

E. coli was inoculated in boneless, skinless trout fillets and incubated until the microbial population reached 109 colony-forming units (CFU) per gram. Although this extremely high level of contamination would be very unusual for industrial settings that apply good manufacturing practices, it is commonly used for determination of pathogen inactivation in challenge studies.

The contaminated fillets were subjected to e-beams at 0, 0.5, 1.0, 2.0, 2.5 and 3.0 kGy, followed by enumeration of survivors and determination of the D-values. The fillets were e-beam processed while frozen, chilled, or at room temperature. The water availability for microbial reactions and growth, and salt content of the trout fillets were adjusted to three levels.

The D-values ranged 0.19 to 0.33 kGy, depending on the treatment variables (Fig. 2). Assuming linearity of the D-value, e-beam processing of chilled trout fillets at 3 kGy would result in a 12-D reduction, the safety level used in canned foods. Unlike canning, e-beams provide microbial safety without heat application, so fresh fish fillets can retain their “fresh” identity.

(Editor’s Note: This article was originally published in the June 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Jacek Jaczynski, Ph.D.

West Virginia University

Animal and Veterinary Sciences

G004 Agricultural Sciences Building

Morgantown, West Virginia 26506 USA[117,100,101,46,117,118,119,46,108,105,97,109,64,105,107,115,110,121,122,99,97,106,46,107,101,99,97,106]

Tagged With

Related Posts

Responsibility

Are seafood safety requirements pointing to vertical integration?

Vertical integration to control the product from the first stages of production through packaging is an excellent way to minimize preventable risks.

Intelligence

4-hexylresorcinol: sulfite-free control for melanosis in crustaceans

4-hexylresorcinol in a nonsulfite processing treatment against melanosis in crustaceans inhibits natural enzymes for shell hardening.

Health & Welfare

Achotines laboratory home to continuing studies of tuna early life history

The Inter-American Tropical Tuna Commission Achotines Laboratory in southern Panama is the world’s only facility with nearly year-round availability of tuna eggs and larvae. A study is comparing the reproductive biology, genetics and early life history of yellowfin and Pacific bluefin tuna.

Health & Welfare

Algae alternatives serve in larval rearing of sea bream

Sea bream fry are produced using the greenwater technique in which microalgae are added to larval-rearing tanks during the first 20 to 30 days after hatching.