Considerations for water quality management

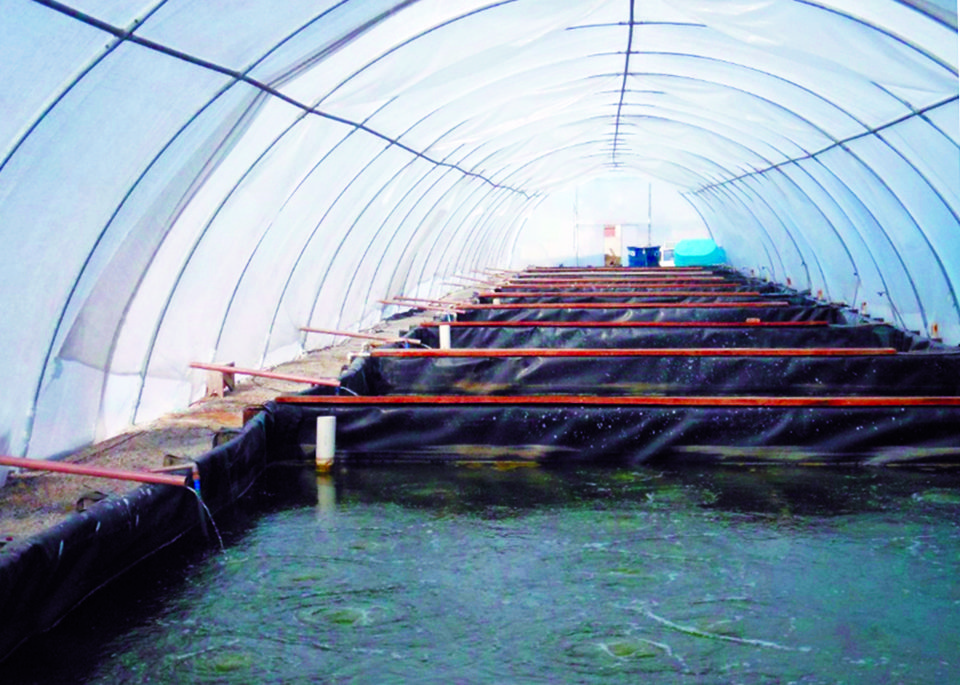

Marine shrimp aquaculture systems that incorporate biofloc technology often experience a high density of suspended solids within the systems. The injection of air at the bottoms of culture tanks promotes both the diffusion of oxygen in the water column and mixing of suspended material. The use of lined tanks increases the confinement of biofloc in the culture environment and restricts the organic particles in the water column from being recycled completely.

Suspended solids

Suspended solids consist mainly of organic matter, which is comprised of microbial forms that when decomposing exert a high demand for oxygen. This demand can decrease the dissolved-oxygen concentrations in the culture system to reach levels below the recommended concentration for the cultivated species. An increase in suspended solids can also reduce the water quality within the system (Table 1). Overall, these less-than-optimal conditions reduce system performance.

Gaona, Changes in water quality parameters, Table 1

| Parameter | Effect |

|---|---|

| Ammonia | Increase |

| Nitrite | Increase |

| Nitrate | Increase |

| Phosphorus | Increase |

| pH | Increase |

| Alkalinity | Decrease |

| Dissolved oxygen | Decrease |

| Carbon dioxide | Increase |

These conditions can occur throughout the different stages of the marine shrimp production cycle, depending on whether the system starts a cycle with mature biofloc inoculum. However, the use of biofloc inoculum relates to the suspended solids concentration in the water column.

At the beginning of a cycle, interactions among the nitrogenous compounds, ammonia and nitrite are most notable when biofloc is forming in the culture. The reduction of ammonia occurs with the establishment of ammonium-oxidizing bacteria, which does not require the use of organic carbon, and with the absorption of heterotrophic bacteria. Therefore, the nitrite accumulation occurs due to the slow growth of nitrite-oxidizing bacteria.

Total suspended solids levels constantly increase, and consequently nitrite concentrations increase. In contrast, when a cycle begins with a well-stocked biofloc inoculum, the concentrations of ammonia and nitrite are relatively low. However, the concentrations of suspended solids are higher in this phase. Both situations require management of suspended particulate matter within the culture system.

Experimental work

In experiments conducted with Litopenaeus vannamei shrimp in biofloc systems at the Marine Aquaculture Station of the Federal University of Rio Grande in southern Brazil, the best growth performance occurred in a study where suspended solids were removed for the maintenance and control of the total suspended solids concentrations in culture inoculated with biofloc.

In another experiment, concentrations of nitrogen compounds differed when compared to different total suspended solids (TSS) concentrations during the formation of biofloc. Higher TSS concentrations resulted in higher concentrations of nitrite.

In another experiment that used the biofloc inoculum, it was observed that when the concentration of dissolved oxygen was maintained above 5 mg/L, the suspended solids excess was not a problem for the respiration of the reared shrimp. Considering the interactions of water quality parameters listed above, maintenance of the suspended solids levels is required for better water quality. Values for common water quality parameters measured under two average TSS concentrations are shown in Table 2.

Gaona, Water quality parameter values, Table 2

| Parameter | 200 mg/L TSS | 800 mg/L TSS |

|---|---|---|

| Dissolved oxygen (mg/L) | 5.90 | 5.10 |

| pH | 7.95 | 7.40 |

| Alkalinity (mg calcium carbonate/L) | 160 | 100 |

| Ammonia (mg/L) | 3.50 | 2.50 |

| Nitrite (mg/L) | 1.00 | 15.50 |

| Nitrate (mg/L) | 5.00 | 80.00 |

| Phosphate (mg/L) | 0.50 | 6.00 |

Monitoring, intervention

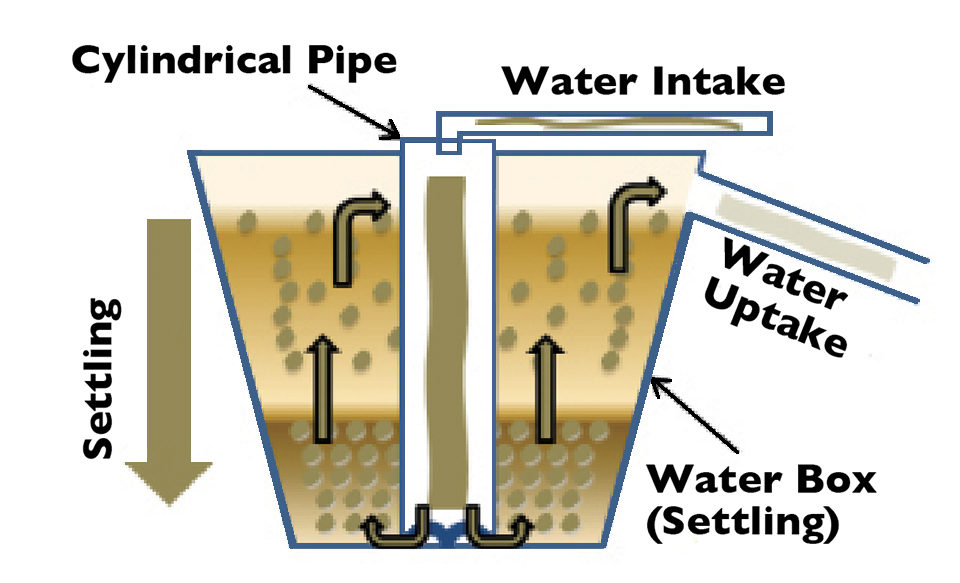

Measurements of suspended solids were made using the gravimetric method, which measures total suspended solids and settleable solids within an Imhoff cone. Various techniques can be applied to reduce and maintain suspended solids concentrations, such as the use of a settling chamber or clarifier to remove solids. Set up in straightforward settling chambers, clarifiers rely on gravity to move particles to the bottom (Fig. 1).

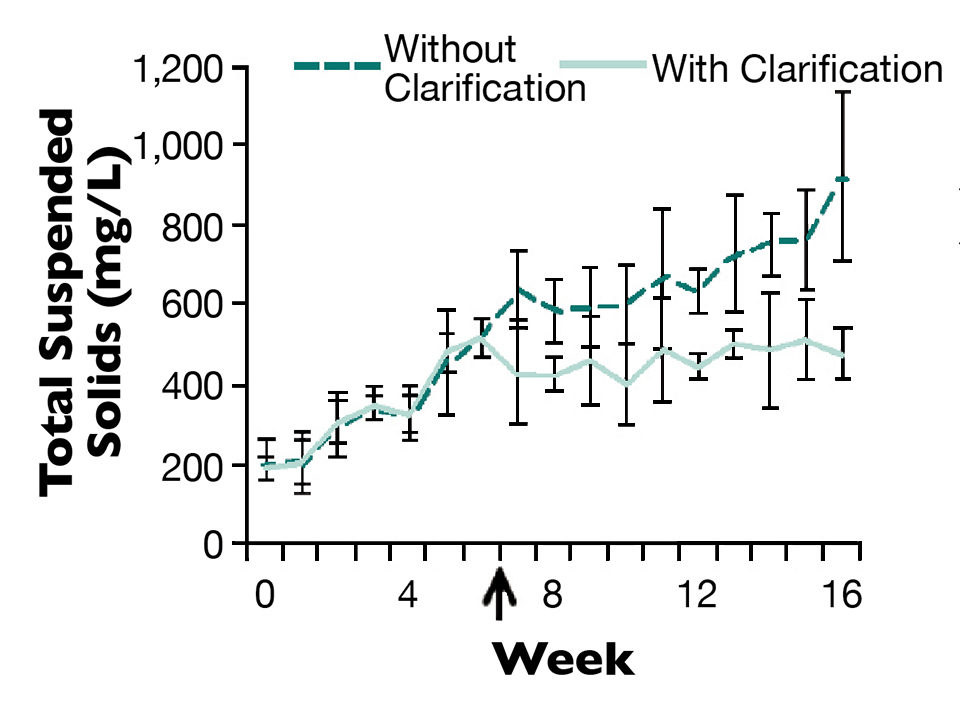

The radial water flow in the settling chamber can be adjusted based on prior analysis of biofloc sedimentation in an Imhoff cone, increasing the efficiency of the method. This method allows the control of TSS and keeps the concentrations near the recommended values (Fig. 2). Another advantage of this method is maintaining a constant flow during the application of settling, so a small amount of water is sufficient for removing suspended solids.

(Editor’s Note: This article was originally published in the November/December 2013 print edition of the Global Aquaculture Advocate.)

Authors

-

Carlos Gaona

Laboratório de Carcinocultura

Universidade Federal do Rio Grande

Rio Grande (R.S.) 96201-900 Brazil -

Plínio Furtado

Laboratório de Carcinocultura

Universidade Federal do Rio Grande

Rio Grande (R.S.) 96201-900 Brazil -

Fabiane Serra

Laboratório de Carcinocultura

Universidade Federal do Rio Grande

Rio Grande (R.S.) 96201-900 Brazil -

Luis Poersch

Laboratório de Carcinocultura

Universidade Federal do Rio Grande

Rio Grande (R.S.) 96201-900 Brazil -

Wilson Wasielesky, Ph.D.

Laboratório de Carcinocultura

Universidade Federal do Rio Grande

Rio Grande (R.S.) 96201-900 Brazil[114,98,46,109,111,99,46,115,117,114,107,105,109,64,119,111,110,97,109]

Tagged With

Related Posts

Aquafeeds

Biofloc and clear-water RAS systems: a comparison

This study compared two types of indoor, shrimp culture systems: clear-water RAS and biofloc systems. Clearwater RAS had the edge in water quality, but shrimp in the biofloc treatment had a higher feed conversion ratio.

Aquafeeds

Biofloc systems viable for tilapia production

Well-designed and managed biofloc technology systems are a viable alternative for production of various species like tilapia, to increase feed efficiency by lowering aquafeed protein requirements and to help reduce or eliminate effluent discharges.

Health & Welfare

Biofloc technology holds potential for carnivorous fish species

Juvenile carnivorous African catfish performed well in biofloc-based systems, which could help produce better quality and more disease-resistant seed of this important aquaculture species and support the expansion of African catfish farming industry.

Responsibility

A look at unit processes in RAS systems

The ability to maintain adequate oxygen levels can be a limiting factor in carrying capacities for RAS. The amount of oxygen required is largely dictated by the feed rate and length of time waste solids remain within the systems.