Results indicate the farm is efficient producing tilapia fingerlings

Biofloc technology (BFT) has been successfully applied to culture tilapia, one of the most produced fish species in the world. The numerous benefits of the BFT technology require an appropriate infrastructure and level of support services. For example, the need for specialized labor, constant water quality monitoring and the dependence on electricity to maintain appropriate aeration and water movement are usually reported as drawbacks of biofloc-based production.

A holistic understanding of the BFT operation and microbial interactions and how to maintain the water parameters suitable for each target cultured species are important to profitably run a BFT system. Sustainability assessments are essential tools to assist in formulating public policies, pointing out the problems, and indicating alternative practices aimed at sustainable aquaculture. Thus, over the last few years, emergy synthesis has been used to measure the sustainability of different aquaculture systems.

Emergy synthesis is a method that allows measuring the direct and indirect energy required to make a product and/or sustain a system. Moreover, this assessment can incorporate environmental, social, and economic aspects into a common unit of measure, the solar emjoule, sej [where j stands for a joule, a unit of available energy] providing indicators to estimate efficiency and sustainability throughout the production process.

This article – adapted and summarized from the original publication (David, L. et al. 2021. Assessing the sustainability of tilapia farming in biofloc-based culture using emergy synthesis. Ecological Indicators, Vol 131, 108186) – presents the results of a study to investigate and apply emergy synthesis to assess the sustainability of a biofloc-based culture in a commercial BFT farm that produces Nile tilapia (Oreochromis niloticus) fingerlings as a case study.

Study setup

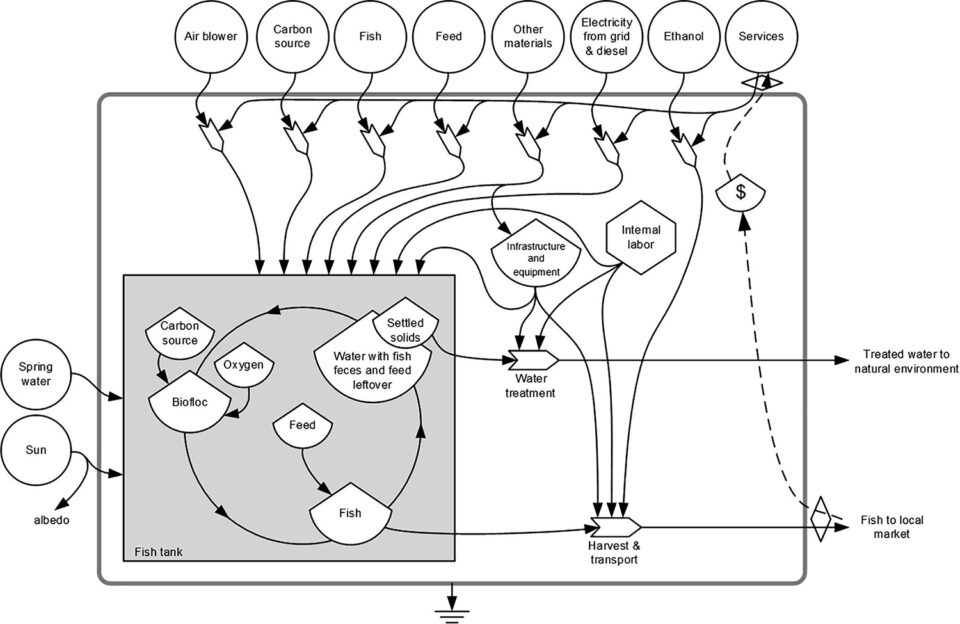

Our study assessed the sustainability of a commercial BFT farm of Nile tilapia fingerlings in the city of Sales Oliveira, São Paulo State, Brazil. Data on the investment in infrastructure, productive performance, production inputs and outputs, and information about the operation of the system were collected through a questionnaire, measurements in the field and observation by the authors. Fig. 1 presents the scope boundaries of the BFT system. All data collected correspond to one year of production.

The BFT system consisted of 10 production tanks, with a volume of 50 cubic meters each, inside a greenhouse covered with a shading net to reduce luminosity. Aeration was provided continuously by a traditional air blower and distributed in the tanks by micro-perforated diffusers to promote constant oxygenation and horizontal and vertical movement of the water.

The electricity used on the farm to support aeration and heating of the system comes from a hydroelectric plant. Heating was used in the tilapia masculinization process to maintain the water temperature at around 35 degrees-C. After this process, the heater was only needed when the water temperature was lower than 27 degrees-C. The farm had an electricity generator as a backup for eventual power failures.

The fish tanks were stocked with tilapia fingerlings with an average weight of 1 gram. When the fish reached the weight of approximately 5 grams, they were harvested and sold to farmers who produce tilapia in ponds or cages. The emergy input of tilapia was not accounted for in the synthesis since fish with such low weight (1 gram) would certainly have low embodied emergy, and thus, the input of it was considered negligible.

Three different feeds were used during one production cycle, and the dietary protein levels (57, 45 percent crude protein) were lowered as the fish grew. The biofloc community was already established, at a C:N ratio of 15:1, and the addition of sugar cane as a carbon source used to support the biofloc community depended on the concentration of ammonia in the water of each fish tank.

The labor activities carried out at the BFT farm were fish stocking, fish feeding, periodic biometrics, harvesting, water quality monitoring and general cleaning of the system. These activities were performed by five employees who dedicated eight hours per day to operate the system manually.

For detailed information on the experimental design and BFT system used; emergy indicators; sensitivity analyses; and data collection and analyses, refer to the original publication.

Results and discussion

This study applied emergy synthesis to assess the sustainability of commercial production of Nile tilapia fingerlings (1 to 5 grams) in a BFT farm, and all results and points of discussion are specific to the evaluated farm and its management. Although each production has its particularities, the evaluated farm manages and employs structures well accepted and adopted in the BFT field. Our study is the first emergy synthesis of a production system using BFT and provides relevant insights to discuss its general sustainable character.

Overall results showed that the experimental BFT farm used 3.20 X 1014 sej per square meters per year to produce 6,000 kg per square meter per year of tilapia fingerlings. Resources from the larger economy had higher emergy demand, represented mainly by electricity (57.5 percent) and infrastructure and equipment (28.9 percent). The sensitivity analysis shows that replacing the source of electricity from hydroelectric by photovoltaic reduced the emergy demand and the Unit Emergy Value, UEV [which measures the environmental cost of a given resource] by 78 percent. However, the other indicators were negatively affected when simulating the use of photovoltaic electricity.

Unlike most aquaculture systems assessed by emergy, feed was not the most representative item in the synthesis of the BFT farm. This was probably due to the low amount of feed usually needed in this production phase, and also a result of the biofloc uptake by tilapia fingerlings as a complementary food source. Keeping the bioflocs available in the fish tank requires input from other energy sources. Thus, electricity was the item with the greatest representativeness in the emergy input, making the system dependent on resources from the larger economy.

We also determined a high demand for infrastructure, an expected result since BFT systems need a controlled environment with efficient hydraulic and electrical systems. This infrastructure comprises mainly plastic and other materials with a short useful life and low renewability, increasing the system’s emergy demand. Moreover, the high need for equipment to control the operational parameters of the system, especially water quality, is another factor that contributes to the high emergy input. The need for constant water quality control is due to increased organic load and nutrient concentration in the water and the high demand for oxygen and water alkalinity by the biofloc microbial community. Thus, to enable the bioflocs uptake by tilapia fingerlings as a complementary food source, high emergy for electricity and infrastructure is required, and thus clearly shows the trade-off between feed and electricity.

One of the main characteristics of biofloc-based production is the low water footprint due to the minimal dependence on water replacement and effluent discharge. However, in the emergy synthesis method, the source and quality of the water that returns to the environment affect the system’s sustainability results more than the volume of water used. As the farm evaluated did not perform any treatment on the discharged effluents/solids, it was considered a disservice. To account for and solve this disservice, we included a device for solids treatment (biodigester) in the synthesis.

Another possible alternative to mitigate this disservice could be using the nutrient-rich solids for other purposes, such as an ingredient in fish/shrimp diets or plant fertilizer. In general, the BFT farmer could improve the management of the exceed settled solids (biofloc biomass) to obtain a better emergy performance, and consequently a more sustainable production. That means not discharging the effluent/solids or at least treating them to return to the environment with the same or better quality as the incoming water.

The emergy indicators resulting from the BFT farm assessment are characteristic of potentially sustainable production systems. The low UEV found indicates that the BFT system used by the evaluated farm is efficient in the production of tilapia fingerlings in terms of converting the invested emergy into the system’s outputs. The BFT system seems to be even more efficient when compared to traditional production systems such as cages, also recognized as intensive aquaculture system.

Accounting for the renewable fraction of all the inputs used in the system allowed us to reach precise values of the emergy indicators, mainly renewability. The use of resources with high renewable fractions, such as electricity from a hydroelectric plant, guaranteed high renewability for the BFT farm. This result indicates that the system has a high chance of staying in operation over time. The system renewability can reach values even higher if management that aims to replace the non-renewable or low-renewability inputs with renewable or high-renewability resources is applied.

Despite the high renewability, the Emergy Yield Ratio, EYR [ratio of emergy in the yield to that required from the economy for extraction and processing] we determined confirmed that most of the BFT farm’s inputs were resources from the larger economy. One of the issues that these findings points out is that the BFT farm is highly susceptible to market variations and resource availability over time.

The values we found for the Emergy Investment Ratio, EIR [ratio of purchased emergy to the local free environmental emergy] and the Environment Loading Ratio, ELR [ratio of non-renewable and imported emergy use to renewable emergy use] are related to the non-inclusion of non-renewable resource items in the emergy synthesis. The EIR suggests that the amount of renewable resources used by the BFT farm was low compared to non-renewable resources. The EIR indicates that the evaluated farm was not efficient in using local resources.

All these results highlight the need to develop new techniques or products applicable to BFT systems to reduce the use of resources from the larger economy. For the ELR, the low value obtained suggests that the BFT production process generated a low pressure on the environment. In contrast, the Emergy Sustainability Index, ESI [the ratio of EYR to ELR] shows that despite the low environmental load, the impact of the production process on the economy was low in relation to the environmental stress generated.

Replacing the electricity from a hydroelectric source with photovoltaic did not improve the overall emergy performance of the BFT farm, as expected beforehand. Despite reducing the emergy demand and the UEV of the system and not changing the EIR, all other indicators worsened after replacing hydroelectric by photovoltaic sources. The reduction in renewability was due to the need for a large amount of materials with a low renewable fraction in the manufacture of solar panels, such as photoactive materials, glass, and steel. Furthermore, adopting the photovoltaic as the primary source of electricity excludes the electric input from hydroelectricity, which has a high renewable fraction (68 percent) and helped in the high renewability (32.7 percent) of the original assessment.

The unchanged EYR in the simulated scenario indicates that even replacing the electricity from hydroelectric by photovoltaic, the resources from the larger economy still play an essential role in the BFT farm. The environmental load generated by the system also increases by the adoption of solar panels, a result verified by the high ELR. The ELR result suggests that the BFT farm, when using photovoltaic as an electricity source, ceases to be similar to a natural production process and becomes comparable to industrial systems.

The use of photovoltaic electricity was evaluated because it is recognized as a sustainable alternative available in Brazil. Also, a grid-connected solar photovoltaic system could be a feasible option for small-scale farmers. However, we encourage investigations on other renewable electricity generating options for BFT farms, such as wind. This source of electricity has been included in the energy matrix of many countries, including Brazil, due to its considerable thermodynamic efficiency with the lowest UEV among various electricity generation processes.

Future research should focus on reducing the electricity dependence of BFT instead of only changing the electricity source. Also, research on the use and sustainability of more efficient aerator systems is highly recommended. For example, compressor or centrifugal blowers consume less energy and are up to 60 percent more efficient in maintaining water oxygenation than traditional air blowers like the ones used in the BFT farm assessed. Other potential means to improve the sustainability performance of BFT systems that must be investigated are reusing the discharged solids to avoid the generation of disservices or even diluting the non-renewable resource input per kg of food produced by integrating it with soil-less plant production in a FLOCponics system (https://doi.org/10.1016/j.aquaculture.2021.736932).

Perspectives

Overall, our results show that, from the point of view of emergy synthesis, the BFT system used by the farm proved to be efficient for producing tilapia fingerlings. We observed that the use of photovoltaics as an electricity source did not improve the BFT farm’s sustainability. Despite the high use of resources from the larger economy, the emergy indicators showed that the production process has potentially sustainable characteristics, capable of keeping the system running over time.

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Luiz H. David, M.Sc.

Corresponding author

São Paulo State University (Unesp), Aquaculture Center of Unesp, Jaboticabal, São Paulo, Brazil -

Sara M. Pinho

São Paulo State University (Unesp), Aquaculture Center of Unesp, Jaboticabal, São Paulo, Brazil; and

Mathematical and Statistical Methods (Biometris), Wageningen University, P.O. Box 16, 6700 AA Wageningen, the Netherlands -

Karel J. Keesman, Ph.D.

Mathematical and Statistical Methods (Biometris), Wageningen University, P.O. Box 16, 6700 AA Wageningen, the Netherlands

-

Fabiana Garcia, Ph.D.

São Paulo State University (Unesp), Aquaculture Center of Unesp, Jaboticabal, São Paulo, Brazil; and

Fisheries Institute, APTA/SAA, São José do Rio Preto, São Paulo, Brazil

Tagged With

Related Posts

Responsibility

Direct energy use in channel catfish production

The direct energy input values for aquaculture include energy used in constructing facilities, producing seedstock and feed, powering mechanical aerators, applying feed and harvesting and processing culture animals.

Responsibility

In-pond raceway system demonstrates economic benefits for catfish production

Auburn University researched how to improve economic efficiency and profitability of catfish production with in-pond raceway systems. IPRS systems help achieve high levels of feed performance and fish survival, and lower production costs.

Health & Welfare

RAS polyculture of channel catfish, Nile tilapia

High-density RAS polyculture of channel catfish and tilapia in tanks or raceways has several advantages over traditional pond culture.

Health & Welfare

Sizing up TiLV and its potential impact on tilapia production

An international research effort has commenced to find a solution for Tilapia Lake Virus (TiLV), a contagion causing high rates of mortality in farmed and wild tilapia stocks in Israel, Colombia, Ecuador, Egypt and Thailand.