Ingredient functionality of formulas

Aquatic feed formulas define a complex mixture of ingredients designed to fulfill the nutritional requirements of the target species. Each ingredient in a formula plays an important role in the amount of nutrients it supplies, but also interacts with others during the process to produce the final product. Depending on the processing conditions and ingredients used, different products such as floating or sinking extruded feed can be produced.

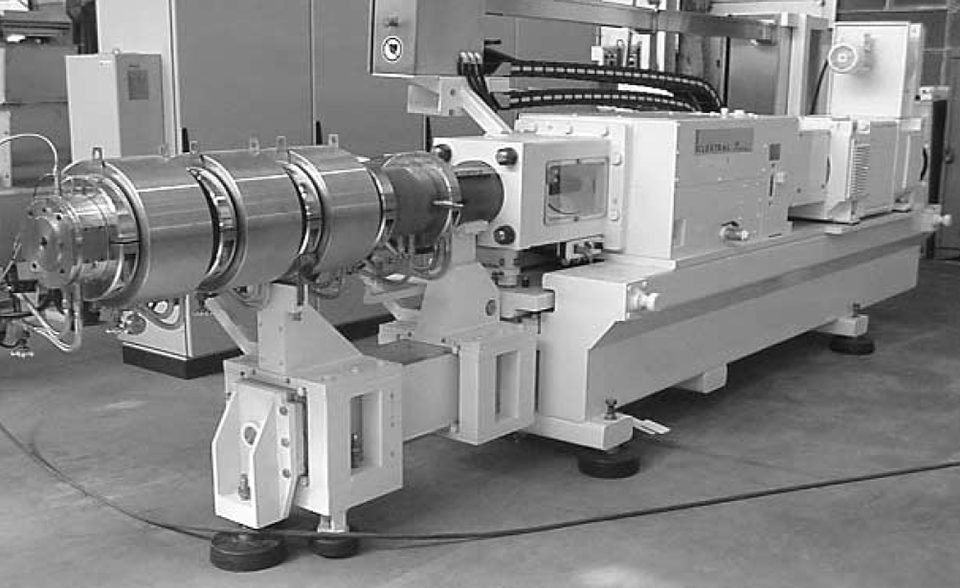

Extrusion process

Extrusion cooking involves the application of mechanical energy supplied by the shearing and mixing action of the extruder screws. During the process, a formula mix is transformed from a powdery, free-flowing meal into a dense, compact powder. As temperature and pressure increase in the last section of the extruder, the powder phase melts to form what is known as the fluid melt phase. In the last section of the extruder, the water contained in the melt is superheated and in a liquid phase.

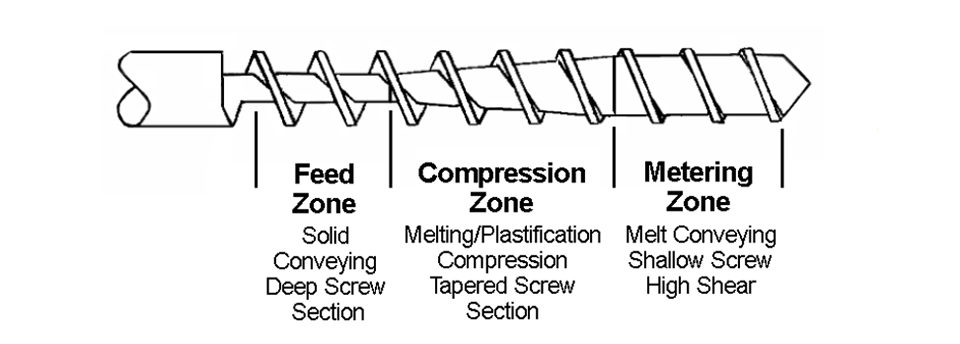

Fig. 1 is a schematic view of a single-screw extruder with different zones. The first section is the feed zone, where the formula mix is added to the extruder. This zone is characterized by deep channel screws designed to convey. The next zone is the compression zone, which has shorter-pitch, flighted screws and shallower channel depth. Its objective is to start applying mechanical energy to the mix, thus initiating the cooking process. In this zone, the material starts melting.

In the final zone, where the molten materials become a plastic, amorphous melt, the highest pressures and temperatures are achieved. The screw elements have even shallower channels and pump out the molten phase through the die. Upon exiting the die, the melt is suddenly exposed to the lower atmospheric pressure, which changes the superheated water into vapor, resulting in what is known as expansion.

Typical shrimp formulas contain the following categories of ingredients: protein sources (fishmeal, soy bean meal, other marine byproduct meals), starch sources (wheat and rice flour), water, fats and oils, fiber (in some ingredients), and minor ingredients like vitamins and minerals. Each group of has an effect on the final product and processing conditions.

As ingredient formulation is changed, one has to be aware that processing conditions in the extruder must also change. In some cases, a different screw configuration is required to accommodate drastic formula changes.

Proteins

Proteins are formed from chains of amino acids and, depending on the source, can have different sizes. They are classified according to their solubility:

- Water-soluble: albumins

- Soluble in saline solutions: globulins

- Soluble in 40 percent alcohol: gliadins (part of wheat gluten)

- Insoluble in 40 percent alcohol: gluten – in (part wheat gluten).

During the extrusion process, proteins form a disperse phase within the starch matrix. Under the effect of high shear and temperature, some proteins – in particular water-soluble proteins like albumins – denature and coagulate. However, due to the shearing action of the screws, the protein is macerated into very small pieces.

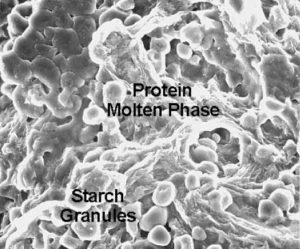

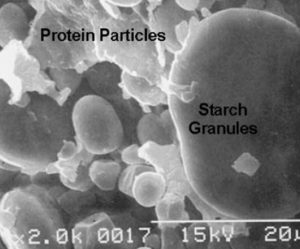

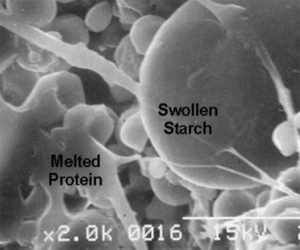

Proteins from oil seeds like soybean meal and wheat gluten form viscoelastic doughs as they are hydrated with water. But as shear increases by the action of the screws and other particles rubbing against each other, the proteins are also macerated into smaller particles. Fig. 2 shows a protein melt phase in the fluid state surrounding starch granules that have not ruptured. In contrast, proteins from muscle origin (fishmeal, poultry meal, etc.) are more resistant to the shearing forces than the oil seed proteins and can retain their original particle size.

In an extrusion process with high moisture over 35 percent, temperatures exceeding 140 degrees C, and high pressure and shear, globular proteins like soybean meal and wheat gluten can be dispersed to form a continuous melt. In this fluid state, the protein flows like a liquid, but if subjected to lower temperatures, becomes laminar and cross linking occurs.

If the protein matrix is allowed to flow continuously at low temperatures, it forms stream lines (cross-bonding). Once it exits the die, the water evaporates and leaves small voids within the cross-linked structure. Therefore, depending on the type of protein and process conditions (water content, screw speed, screw configuration), one can control the type of structural integrity of the feed. This is of particular importance if the objective is to change protein attributes like solubility and overall physical integrity.

Proteins are denatured in the extruder, which is believed to improve their digestibility by exposing the molecules to more enzyme access sites. The protein denaturation is usually measured based on protein solubility in water or aqueous solutions. Lower solubility is indicative of a high-shear process in which more protein is denatured. However, some proteins may not require high shear to be denatured or have low solubility. An example of this is wheat gluten, which can be denatured at low screw speeds.

Starch

Starches are a source of energy in aquatic feeds, but also play an important role as natural binders and density control agents. Starches are found in cereal grains, potatoes, and cassava. Starch is physically present in cereals in small aggregates of polymer molecules known as granules.

There are two physical forms of starch, amylose and amylopectin. Amylose is a linear polymer of glucose units with one or two branches. Amylopectin, a much larger molecule, is a branched polymer of glucose units.

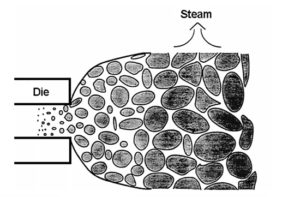

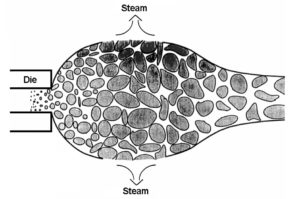

In the extrusion process and in the presence of water, the starch granules first hydrate and swell (Fig. 3). In the compression zone, the starch swells even more and the protein starts to form a molten phase (Fig. 4). As more energy is imparted, the granules soften and eventually rupture to form a continuous melt fluid.

If more shear is applied, the starch molecules are macerated even further into smaller chains of glucose units. This is known as dextrinization. Highly dextrinized starch tends to absorb water more readily, which can be a problem for water stability. Therefore, if a feed is made under high shear conditions, one can expect the pellets to hydrate fast and have poor water stability.

Starch also plays an important role in floating feeds, because of the continuous phase and expansion achieved with starch. In high-protein formulas, at least 10 percent starch is required to achieve feed buoyancy. Starch also helps maintain the integrity of the extrudate as it leaves the die by forming a continuous phase with the protein.

Water

In the extrusion process, water is intrinsic in the ingredients and is also added via steam condensation in the preconditioner or directly into the extruder barrel. As water is added in the extruder to levels greater than 10 percent, the biopolymers hydrate and move more freely.

Water can be used to control the density of the final product. At high levels, water acts as a lubricant and can reduce the amount of mechanical energy input. Low water addition results in higher temperatures in the extruder from greater friction with the screws, barrel, and particles.

At high moisture levels, the feed product exhibits elastic recoil as it leaves the die. This is because the extruded material is still pliable enough to bounce bank until it reaches the glass transition temperature. At lower moisture, the extruded material sets or becomes glassy very quickly, resulting in larger cells.

The expansion resulting from low and high water levels are shown in Figs. 5 and 6, respectively. Products made with water addition over 30 percent tend to have higher density and smaller dimensions (expansion coefficients) than products made with low water addition.

Lipids

Similar to excess water, oils and fats act as lubricants between the particles and the screws of the extruder. Oil reduces the friction between the particles in the mix and between the screw surfaces and the liner of the barrels. If oil is added at levels greater than 2 percent of the total mix, it causes the starch granules to melt, but they will not disperse. This results in a lower temperature of the molten phase in the last section of the extruder, with little or no expansion as it exits the die.

In some aquatic feed formulas with high protein content and intrinsic oil levels over 2 percent, products with very little expansion result. This can be a problem if the product specification for the target species requires it to be a floating feed.

In most cases, high-protein diets require a minimum of 8 percent starch to ensure adequate bulk density less than 550 grams per liter. Therefore, if oil is added in the product to meet the energy requirements, this must be done after the extrusion process via a coating unit. In high-fat formulas, the screw configuration can be changed to a more aggressive or higher energy profile to increase the mechanical energy input and ensure extrudate floatation.

Oil can be added in the extruder to control product density. Therefore, by manipulating oil addition, one can produce sinking or slowly sinking feeds. However, if oil is added, it should be done according to the target energy requirement of the species. Oil added in excess can have drastic effects on feed consumption and/or utilization by the target species.

A concern with lipids addition in the extruder is their oxidation, which can affect the vitamin stability and other organoleptic attributes of the feed. There is no evidence that lipid oxidation occurs in the extruder, but pro-oxidant materials released into the mix as a result of screw wear can produce oxidation. Also, it is possible that the air cells formed during expansion contribute to the oxidation process.

Fiber

Fiber in aquafeed is found in most cereal grains, and some formulations may include bran. Like starch, fiber is also a polymer of glucose units but with a different linkage between the molecules. This different link, beta 1-4 versus alpha 1-6 for starch, is what makes fiber indigestible to most species except bacteria, which produce the enzyme beta amylase.

Fiber does not affect the mechanical energy input in the extruder, but does not expand very well. The bran particles have little effect at low concentrations of 1 to 2 percent, but as levels increase over 6 percent, this may reduce expansion. Therefore, formulas with high fiber content may produce extruded feeds with poor expansion, low floatability, and poor water stability.

Minerals

Minerals are not changed during the extrusion process. However, some minerals increase bubble formation in the disperse melt fluid phase. The smaller bubbles increase the surface area and can be an advantage when coating feed with oil. Porous surfaces on pellets are preferred in newer vacuum coating systems to achieve better oil penetration and reduce oil migration from feed to packaging material.

Conclusion

Formulas should be designed to perform under an optimum set of processing parameters to achieve the desired product attributes while maximizing its nutritional value and extruder output. Subtle changes made to the formula may require readjusting processing parameters or fine tuning the process. However, major changes made in the formulation may require reoptimization of the process, which may even include changing screw profile.

(Editor’s Note: This article was originally published in the April 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

A look at the SME controlled extrusion process

A study was conducted using a Twin-Screw Extruder equipped with Specific Mechanical Energy (SME) and Density Control valves, to determine the effect of SME on the water stability of shrimp feeds. Further research is needed to evaluate the performance.

Aquafeeds

A look at India’s fish feed industry

India's fish-farming industry makes limited use of modern feeds, providing potential for the feed sector to grow. Commercial feeds are predominantly used for pangasius farming, followed by a rising popularity in carp culture.

Aquafeeds

A look at corn distillers dried grains with solubles

Corn distillers dried grains with solubles are an economical source of energy, protein and digestible phosphorus to reduce feed costs and fishmeal usage.

Aquafeeds

Lipid nutrition of farmed tilapia

The optimum dietary lipid level for tilapia ranges from 10 to 15 percent. Various vegetable oil products show promise as replacements for fish oil in feeds.