Production costs depend on farming systems

In common with poultry and salmon, shrimp have a dietary requirement for 40 or so essential nutrients. However, in marked contrast to commercial poultry and salmon-farming operations, where animals are raised almost exclusively within intensive farming systems and fed nutritionally complete, artificially compounded diets for their entire life cycle, shrimp are currently farmed in a wide range of production systems and fed under an equally diverse array of feeding strategies throughout their life cycle.

Varied systems, varied feeding

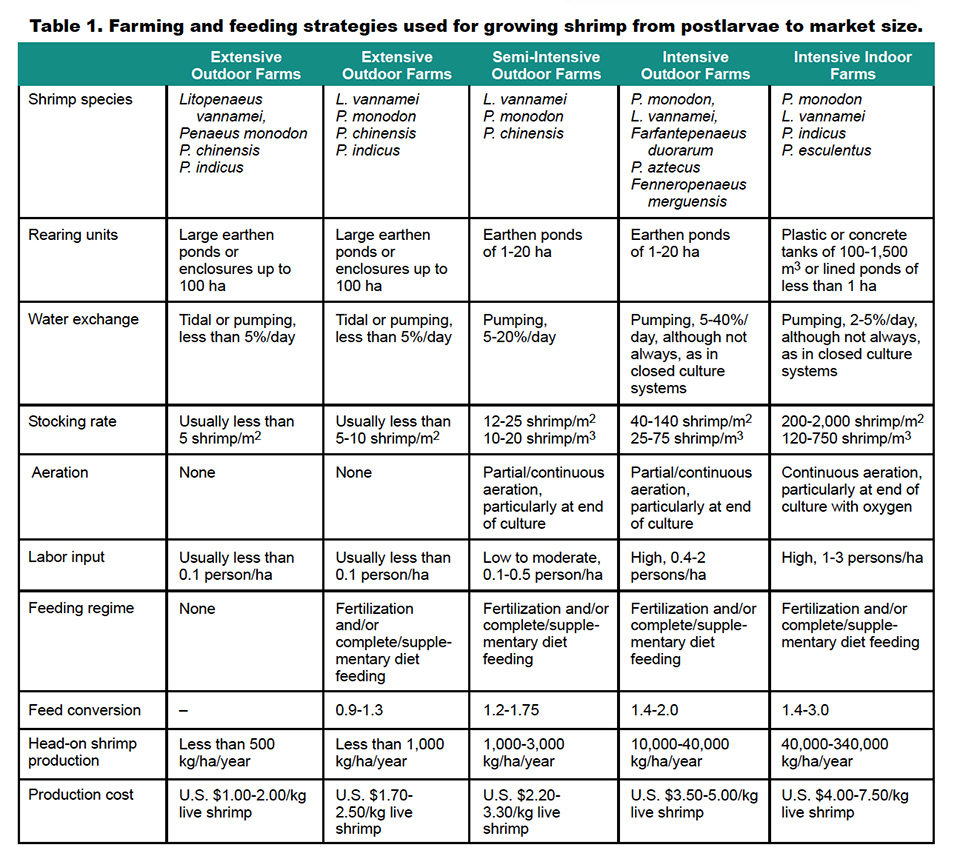

The farming systems and feeding strategies currently employed for marine shrimp vary relative to the shrimp stage of development, culture species, country, and financial resources of the farmers. Some of the varied strategies used to grow out shrimp are shown in Table 1.

At present, no precise statistical information exists on the proportion of current global shrimp production obtained from these different farming systems, either by species or country. Total global production for 2002 was reported simply by the Food and Agriculture Organization of the United Nations in 2004 as 1.29 million metric tons (MT).

As with farming systems, no precise statistical information is available regarding the percentage of farmers who use fertilizers, supplementary feeds, or complete compounded diets. Despite this, it has been estimated that the total aquafeed production in 2002 was about 2.1 million MT. The bulk of shrimp culture and aquafeed production are located within Asia and Latin America.

Feed composition varies widely within and between countries, reflecting species and farming system differences, and the increasing demand by farmers for cheaper feeds rather than possibly more expensive but cost-effective feeds. Limited practical information concerning the dietary requirements of shrimp under practical culture conditions is available.

Costs direct production, feeding

Coupled with often marked differences – even within countries – in farmers’ feeding methods and culture systems, the shrimp industry is currently in a quandary How can it best remain profitable in view of increasing global shrimp production, increasing global concern for the environment, increasing feed ingredient prices, decreasing shrimp prices, and increasing import restrictions due to concerns over perceived food safety risks and/or farming/marketing practices?

The bottom line in any commercial farming operation addresses costs, profitability, and the consequent need to tailor production systems – and feeding costs – to what the market is willing to pay for the final product.

Production costs vary widely depending upon the farming system employed. They can range from as low as $1.00 to 2.00 per kilograms live shrimp for conventional extensive outdoor farming with no external nutrient input to $4.00 to 7.50 per kilograms live shrimp for intensive indoor farming systems with fertilization and/or supplementary or complete diet feeding.

The problem is further compounded by the fact that in some countries, the development of the sector can be constrained by other factors. These factors can include the cost and availability of land, water, power, labor, and feed. National farm-planning regulations and environmental controls, import/export costs and incentives, and proximity to existing markets also play a role.

Practical feed

The consideration of a few basic points can help direct the development of practical shrimp feeds.

Tailor feed formulations. Always tailor feed to the intended shrimp species and farming system, with consideration of shrimp stocking density, water management, and natural food availability.

Recognize natural feeding behaviors. Shrimp do not naturally eat “once or twice during an eight-hour workday,” and will eat continuously if offered food on a little and often basis, as they do in the wild in the absence of predators.

With unrestricted feed access, shrimp have the capacity to grow very fast under both clear water and pond water culture conditions.

For example, growth rates achieved by the first author with Pacific white shrimp (Litopenaeus vannamei) grown at moderate and high densities of 55 and 71 animals per cubic meter on a high-quality, 35 percent-crude protein, fishmeal-based diet averaged 1.44 grams per week in outdoor clear-running water tanks. The animals grew 1.98-13.48 grams over an eight-week period at 26.4 to 29.1 degrees-C.

In outdoor zero-water-exchange tanks, animals grew from 1.58 to 18.89 g at 2.1 grams per week over eight weeks at 28.2 to 31.3 degrees-C. When fed all day, shrimp grew over 3 grams per week from weeks 4 to 6 (Fig. 1).

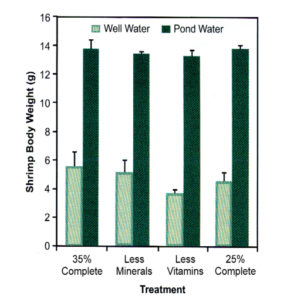

Consider benthic foods. Shrimp have the unique ability to harness food and nutrient particles suspended in the water column and through benthic foraging, in addition to the food provided through compound aquafeeds. In this respect, it is essential to recognize the key nutritional role played by microorganisms in the nutrition and health of shrimp reared under green water or zero-water-exchange culture conditions. Results of a related study are shown in Fig. 2.

(Editor’s Note: This article was originally published in the April 2005 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Albert G.J. Tacon, Ph.D.

Aquatic Farms

49-139 Kamehameha Highway

Kaneohe, Hawaii 96744 USA -

Sergio F. Nates, Ph.D.

Zeigler Bros. Inc.

Gardners, Pennsylvania, USA -

Roderick J. McNeil, Ph.D.

Meridian Aquatic Technologies LLC

Polson, Montana, USA

Related Posts

Health & Welfare

10 paths to low productivity and profitability with tilapia in sub-Saharan Africa

Tilapia culture in sub-Saharan Africa suffers from low productivity and profitability. A comprehensive management approach is needed to address the root causes.

Health & Welfare

A case for better shrimp nutrition

Shrimp farm performance can often be below realistic production standards. Use proven nutrition, feeds and feeding techniques to improve profitability.

Innovation & Investment

Acoustic control improves feeding productivity at shrimp farms

In systems recently developed for shrimp farms, passive acoustic-based technology enables sensor-based control of multiple automatic feeders. Improved growth and feed conversion have been recorded at commercial farms using the technology.

Health & Welfare

Advice for managing predatory birds, part 1

Predatory birds can cause major losses for tilapia farms. As some bird species are protected by law, fish farmers must use non-lethal control techniques.