Extensive, intensive farming methods have differing breeding protocols

The application of genetic improvement programs in the shrimp industry is relatively young compared to their use with other cultured species like salmon and tilapia. Commercial breeding programs for shrimp started with Pacific white shrimp, Litopenaeus vannamei, facilitating the rapid global adoption of this species and displacement of black tiger shrimp, Penaeus monodon, as the most cultivated shrimp within just a few years.

However, unlike those in the salmon sector, shrimp farmers do not follow a common model of cultivation. Those in the Americas mostly apply an extensive, low-density model versus the intensive, high-density model that predominates in Asia. The two cultivation models emphasize different requirements for postlarvae, which presents a challenge to breeding programs trying to satisfy the needs of the two regions.

A second unique characteristic of shrimp versus other species is an industry structure wherein genetic improvement programs are concentrated in a few global programs. Several programs are owned by feed companies that tend to “bundle” feed and fry in servicing shrimp farmers. Some of these breeding programs sell their broodstock to third-party hatcheries in an “open” system, while others maintain a “closed” system of internal hatcheries offering postlarvae but not broodstock to third parties.

Breeding goals

All breeding programs set goals for the performance of their animals and thereby set “economic weights” for various breeding parameters to achieve the goals. In shrimp, there is a clear difference between the traits that are economically important in Central and South America versus those of Asia.

In the Americas, shrimp production tends to be extensive, with stocking densities ranging 10-30 animals/m2 in ponds with areas between 6 and 10 ha. With such large ponds, it is difficult to apply good biosecurity measures and disinfect the water before stocking. Animals in such conditions cohabitate with endemic pathogens, so disease resistance is a critical quality in the postlarvae stocked. In the Americas, shrimp farmers look for specific pathogen-resistant (SPR) rather than specific pathogen-free (SPF) lines.

On the other hand, Asian production systems tend to be intensive, with stocking densities from 90 to as high as 200/m2 in ponds of less than 1 ha that require mechanical aeration. This model requires high biosecurity, disinfection of water before stocking, the use of crab and bird netting, and other measures. Consequently, most viral diseases tend to appear 60 days or more after stocking, when water exchange increases.

Under this scenario, disease resistance is less important than fast growth in a race against time to get the shrimp to harvest size before they are hit by disease. This creates an obsession with average daily growth (ADG) as the only parameter that matters in selecting postlarvae. Hence, in Asia, farmers looking for SPF animals with potential for fast growth.

EMS triggers shifts

However, with the appearance of early mortality syndrome (EMS) in Asia, the focus on ADG became problematic. Mortality appeared earlier, typically during the first 30 days post stocking, and the biosecurity measures applied before didn’t seem to help much. EMS changed the emphasis from ADG to a more balanced breeding model wherein disease resistance (robustness) became more important than fast growth.

It would appear the breeding goals to satisfy Latin American farmers and those in Asia have found common ground in resistance, but Asia still needs fast-growing animals. Since there is a proven negative genetic correlation between fast growth and resistance to at least two major viral disease pathogens (white spot syndrome virus and Taura syndrome virus), it has been very difficult to select animals that fulfill the needs of producers in both regions.

Since growth has a higher heritability than resistance to disease, the progress for that trait is easier to demonstrate at farms. Thus, the breeding companies that were strongest in growth led the market for both postlarvae and commercial broodstock in Asia.

With the global expansion of EMS, some breeding companies modified their breeding goals and applied a more balanced approach including selection traits like growth, pond survival and disease resistance. After all, the ultimate goal is to offer animals that could maximize the value of the customer’s harvest, with lower inputs and higher yield. Survivability has always been an important element of yield, which was perhaps underappreciated in Asia prior to EMS.

Distribution channels

Breeding companies distribute their stocks through two main channels: selling commercial broodstock to independent hatcheries (an “open” system) and selling postlarvae directly to shrimp farmers (a “closed” system). The first approach involves less capital investment, requiring a nucleus breeding center and a broodstock-multiplication facility. Many breeding companies follow this model, since it is easier to manage, and the demand for SPF broodstock is still significant in Asia, especially in China.

There is a threat to this model. Some hatcheries use the animals produced from the original lines of these breeding programs to raise their own broodstock and sell second-generation (F2) postlarvae under the same genetic brand. This is a risk – not only for the breeding companies but also for the farmers, since F2 postlarvae are most certainly inbred.

Currently, breeding companies distribute the commercial stocks from an already narrow genetic base with few families. Hence, reproducing those animals in succeeding generations will result in a high inbreeding level with negative effects on survival, fecundity and growth.

Industry structure

Genetic improvement programs for shrimp have consolidated down to a few large world-class programs in the short history of L. vannamei cultivation. In Asia, feed companies started to develop their own breeding programs or purchased existing breeding companies to offer customers genetically improved seed as well as feed as a competitive advantage against other feed operators. Considering the significant time and investment required to establish a competitive breeding program, this creates a barrier to entry in markets where broodstock and quality postlarvae are in short supply, as in Indonesia and Malaysia, for example.

In Asia, postlarvae distribution may continue to consolidate around programs owned by feed companies that insist on bundled feed/postlarvae purchases. Independent breeding companies can compete with superior-performing animals, but new entrants may find it difficult to penetrate such markets. This is a potentially scary scenario for shrimp farmers who may be forced to buy feed from a supplier they don’t prefer out of desperation to get postlarvae. Thus there is customer support for open systems.

It is worth pointing out that China is the largest global market for shrimp broodstock, yet it lacks a world-class genetic program. However, because China only cultivates for part of the year, it is costly to maintain a breeding program just for this market. We may see genetic programs develop, funded by government or feed companies or independents. However, it will take some time for a new program to close the performance gap with existing programs.

Broodstock segmentation

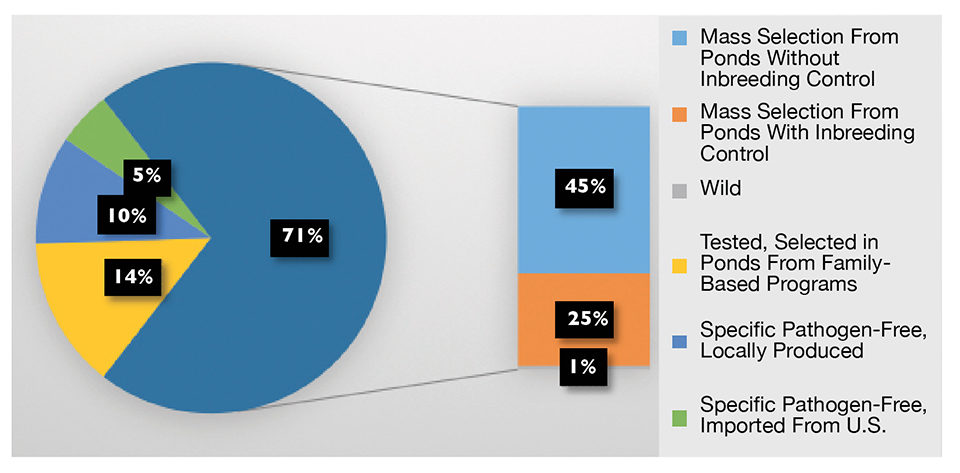

In the Americas, many breeding companies are fully integrated and use their animals for their own production. Many companies use mass selection as their selective-breeding strategy, keeping different lines or populations and crossing them to reduce inbreeding (Fig. 1). This strategy has been successful for local production, but it prevents the possibility of regional or worldwide distribution due to sanitary regulations imposed by the producing countries.

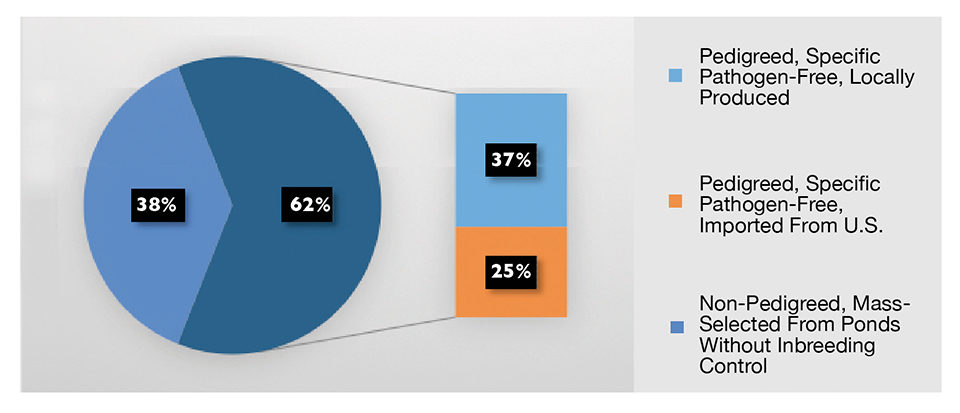

On the other hand, in Asia, the industry follows an SPF broodstock concept, in part because L. vannamei are not endemic to the region. Most of the global breeding programs focus on SPF shrimp for the Asia market. However, we still see many hatcheries using F2 broodstocks selected from culture ponds (Figure 2).

Restrictions imposed by local authorities on moving live animals across borders and their quarantine strategies have resulted in a shortage of high-quality broodstock in some markets. In that scenario, hatcheries began using F2 animals from ponds, which are less costly and more readily available. This practice poses a threat to the industry since there is no inbreeding control, the genetic merit of the animals deteriorates rapidly, and the sanitary conditions of the ponds could easily spread local diseases.

The utilization of F2 broodstocks from local hatcheries is probably the main limitation for the shrimp industry to gain the benefits from selecting breeding and evolve into a mature industry like salmon culture.

(Editor’s Note: This article was originally published in the September/October 2014 print edition of the Global Aquaculture Advocate.)

Authors

-

Thomas Gitterle, Ph.D.

Breeding and Genetics Director

SyAqua Group

140 One Pacific Place 19th Floor

Unit 1902-4, Sukhumvit Road

Klongtoey District, Bangkok 10110 -

John Diener

Managing Director, Aqua Division

Gold Coin Group

Newton, Singapore

Related Posts

Health & Welfare

A holistic management approach to EMS

Early Mortality Syndrome has devastated farmed shrimp in Asia and Latin America. With better understanding of the pathogen and the development and improvement of novel strategies, shrimp farmers are now able to better manage the disease.

Intelligence

Adding value to tilapia to tap into U.S. market

New markets for tilapia and expansion of existing ones can be created by planning and implementing properly designed geographic strategies to meet discriminating consumer preferences. Low labor costs in most producing countries promotes value-adding by the production of fresh fillets.

Aquafeeds

A look at protease enzymes in crustacean nutrition

Food digestion involves digestive enzymes to break down polymeric macromolecules and facilitate nutrient absorption. Enzyme supplementation in aquafeeds is a major alternative to improve feed quality and nutrient digestibility, gut health, compensate digestive enzymes when needed, and may also improve immune responses.

Innovation & Investment

Algae innovators aim to freeze out early-stage shrimp losses

A greenhouse in Belgium believes its innovative shrimp feed product, made from freeze-dried microalgae, packs the necessary nutrients for the crustacean’s most vulnerable life stage: the first three days of its life.