NIR technology improves aquafeed quality by detecting mycotoxins

“You are what you eat” applies to more than just people. For fish, bad feed can stunt growth or even kill. That’s why ensuring the quality and safety of aquaculture feed is critical.

However, a particularly challenging problem arises when mold infests the grain used to make feed. Mold can produce harmful compounds, known as mycotoxins, that are resistant to digestion and sometimes heat. So they can remain in the food chain, impacting the fish and ultimately human consumers.

“Mycotoxins, or fungal toxins, are some of the most potent toxins affecting foods and feeds,” said George Chamberlain, president of the Global Aquaculture Alliance (GAA) and one of the judges of the organization’s annual Global Aquaculture Innovation Award. “These are difficult, expensive and time-consuming compounds to measure.”

Pegasus Science LTDA of Santa Maria, Brazil, one of this year’s Innovation Award finalists, aims to make that measurement easier, according to Technical Director Adriano Mallmann. The company does this through the application of specialized, mycotoxin specific analysis of near infrared (NIR) spectroscopy.

Located adjacent to the visible spectrum, near infrared starts at about 750 nanometers wavelength, or slightly longer than red, and runs out to as much as 3,000 nanometers. When illuminated by the right light, compounds produce invisible-to-the-eye NIR signatures. Measuring these emissions via spectroscopy enables discovery of the chemical makeup of a sample. With NIR spectroscopy, feed makers monitor the crude protein, fat, fiber, minerals and other parameters of incoming materials.

“The nutritionist needs to know the chemical and energy composition of the raw materials so as to produce the feed in such a way that it meets the nutritional needs of the animals that will consume the feed,” Mallmann said.

He added that the mycotoxin detection gold standard is liquid chromatography coupled to tandem mass spectrometry, a mouthful abbreviated as LC-MS/MS. This approach requires specialized equipment, know-how and chemicals. At best, measurement takes a day, with that only possible with a suitable in-house lab. More typical is a seven to 14-day turnaround.

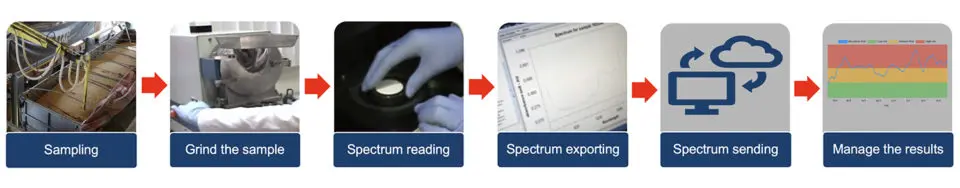

In contrast, NIR spectroscopy involves grinding the grains, reading the spectrum and analyzing the results. It takes a few minutes, according to Mallmann.

There are some other important advantages. No wet chemistry, or traditional analysis in a laboratory setting, is involved, which makes the entire process cleaner, faster and more environmentally friendly. What’s more, NIR spectroscopy is relatively inexpensive. The time and cost of LC-MS/MS means that is it only sparingly used. Unfortunately, mycotoxins are not evenly distributed in grains. They may be in one spot and not another. So, the safest approach is to sample widely.

“The possibility to analyze more samples reduces the sampling error,” Mallmann said.

In the past, issues with NIR spectroscopy kept it from being used to detect mycotoxins. There are a multitude of compounds in any grain, all of which produce their own spectral curves. Thus, what the NIR instrument captures is a mashup of these different spectral fingerprints.

Pegasus Science’s innovation, and secret sauce, lies in the development of advanced analysis methods. With these, the company created an online platform, Olimpo, that allows the determination of statistics, trend curves and risk of contamination in feed raw materials. Currently this is only for those mycotoxins that are the most likely to be present, with work underway to extend coverage.

These are difficult, expensive and time-consuming compounds to measure.

This approach is possible, in part, because Pegasus Science draws upon decades of research at the Federal University of Santa Maria. The NIR method is backed up through calibration with the results of the very precise, gold standard method.

“The limits of quantification and precision of NIR are obviously a little lower than those of LC-MS/MS. Nonetheless, they meet the needs of the animal production field. Moreover, we can analyze substantially more samples with NIR than with any other methodology in real time,” Mallmann pointed out.

Pegasus Science has achieved success in the field in screening for mycotoxins. One company, for example, monitored its mycotoxin risk to decide when to add an agent to combat the problem.

While the focus has been on pig and poultry feed, Mallmann said aquaculture applications could soon take off. Others also see this as a real possibility, with some significant potential benefits.

“Near infrared technology enables a nearly instantaneous measurement with no traditional wet chemistry. This will greatly improve the management of mycotoxins and improve human and animal health,” Chamberlain said.

A wider group will also be weighing in on the technology. Pegasus Science will pitch to the audience at GAA’s 2019 GOAL conference later this month, with attendees casting the deciding votes about the relative significance of the three finalists’ innovations. For Mallmann, winning the award would validate years of effort: “It would mean recognizing work that started 35 years ago that aims to bring a different perspective on mycotoxin control and, especially, to innovate with the use of a tool that facilitates decision making.”

Follow the Advocate on Twitter @GAA_Advocate

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Hank Hogan

Hank Hogan is a freelance writer based in Reno, Nevada, who covers science and technology. His work has appeared in publications ranging from Boy’s Life to New Scientist.

Tagged With

Related Posts

Innovation & Investment

Global Aquaculture Innovation Award 2019 finalist: Arbiom

Global Aquaculture Innovation Award finalist Arbiom is steadily proving the efficacy of its alternative feed ingredient SylPro, made from woody biomass.

Innovation & Investment

Global Aquaculture Innovation Award 2019 finalist: Ace Aquatec

Global Aquaculture Innovation Award finalist Ace Aquatec’s Humane Stunner Universal easily renders fish unconscious for a more humane slaughter process.

Innovation & Investment

Global Aquaculture Innovation Award finalist: Osmo Systems

Zach Stein, CEO and cofounder of Silicon Valley-based Osmo Systems, thinks it’s time aquaculture embraces rapid change through technology. His startup aims to help aquaculture operators automate water quality monitoring systems.

Innovation & Investment

Aquaculture innovators come out of their shells at Fish 2.0

Biannual conference/competition showcased 40 new seafood businesses, or related services, from around the world. Winners were chosen on the strength of the opportunity, meaningful impact and compelling leadership and presentation.