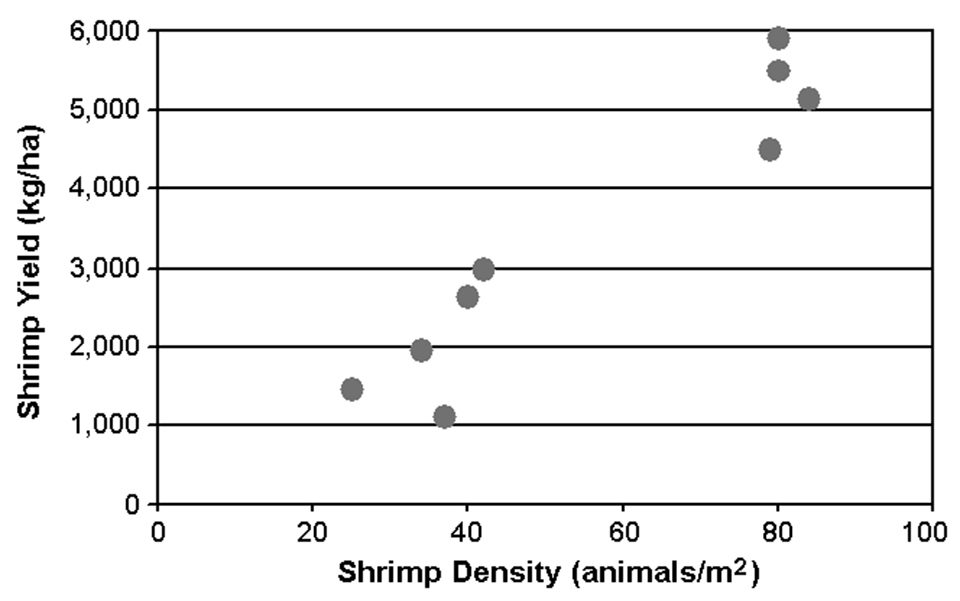

Strong correlation between shrimp density and final yield

Researchers at Ecuador’s Centro Nacional de Acuicultura e Investigaciones Marinas (National Center for Aquaculture and Marine Research, CENAIM) and elsewhere have documented the effects of hyperthermia on the immune systems of Pacific white shrimp (Litopenaeus vannamei) and their survival when challenged with White Spot Syndrome Virus (WSSV). Greater survival and response of cellular defense mechanisms (including increased haemocytes and tissue infiltration, and cell pyknosis and karhyorrexis) were the primary observations reported in these studies of WSSV-infected shrimp at water temperatures above 32 degrees-C.

Greenhouse pond systems

Based on previous laboratory evidence, CENAIM researchers undertook a series of shrimp production tests in 0.05- and 0.25-ha greenhouse-earthen pond systems. The Council of Flemish Universities in Belgium provided financial support for the project.

The first production results were reported in the August 2002 Global Aquaculture Advocate. Yields of 1,500 to 3,000 kilogram per hectare per cycle with survivals of 63 to 70 percent at stocking densities of 24 to 42 shrimp per square meter encouraged further production cycles. A total of 20 nursery and nine grow-out production experiences were carried out in greenhouses until June 2003.

Several commercial shrimp farms started pilot greenhouse projects during 2002 to verify the findings. At present, an estimated 200 ha of shrimp ponds are covered with greenhouse structures in Ecuador.

Greenhouse structures

The main differences in greenhouse designs involve the type and quality of construction materials. The most economical designs use bamboo structures with construction costs that range U.S. $1.20 to $1.50 per square meter. Their durability and maintenance costs will be determined in the next few months.

Concrete and metallic structures are more expensive, but stronger and more durable. They provide better support for the plastic film covers. Drainage of rainwater and resistance to wind are key elements to be considered in material selection and structural design. Investments for the more permanent structures run U.S. $2 to $6 per square meter, but can be amortized over a longer period.

CENAIM’s greenhouse production trials were carried out at the commercial Pesglasa shrimp farm, located in the Taura region of Ecuador’s Guayas Province. The CENAIM greenhouse structure designs there are based on concrete, PVC-protected metal columns, and polypropylene ropes. Building costs were U.S. $1 to $2 per square meter, depending on pond size.

Cover material

Greenhouse designs and the plastic polymer material used to cover the greenhouses need to be improved to allow maximum heat gain and reduced heat escape. The thermal polyethylene polymers commercialized in Ecuador are formulated mainly for horticulture temperature, moisture, and luminous conditions.

Properties of greenhouse polymers for shrimp culture should be based on maximum transparency for visible light radiation and retention of short- and long-wave infrared radiation. Dust accumulation on the outside and water condensation inside reduce light penetration, thus hindering heat gain by the water body enclosed. Illumination records showed a 30 to 40 percent light reduction inside a CENAIM greenhouse.

Water temperature

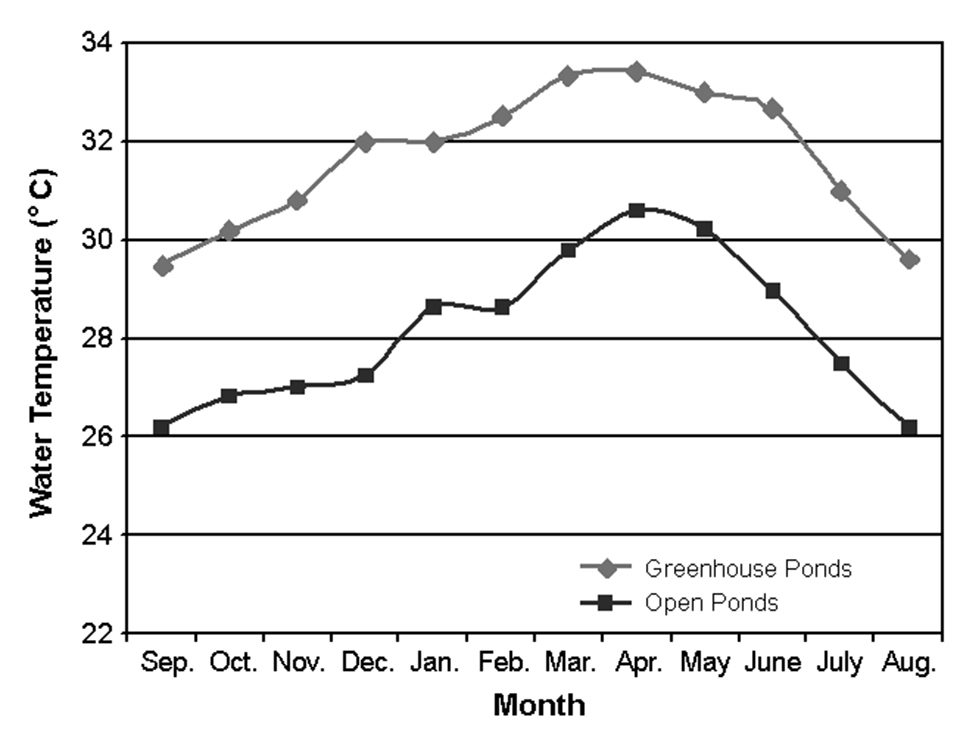

The temperature difference between open ponds and greenhouses ranged 3.5 to 5 degrees-C on average, depending on season and daily weather conditions (Fig. 1). The water temperature curve followed an annual pattern, reaching values of 32 degrees-C and more from December to June. The lowest temperatures occurred during the southern winter season, which is characterized in Ecuador by prolonged cloud coverage.

Temperatures below 31 degrees-C may pose a risk for WSSV outbreaks. However, mortalities associated with WSSV were not documented during this part of the year in production trials. At least one farmer reported WSSV-associated mortalities as greenhouse temperatures dropped below 31 degrees-C.

The authors expect that improvements in polymer properties could result in the 1 to 2 degrees-C water temperature gain required for the colder season. Through a joint project with Repsol YPF, Spain’s largest oil company, CENAIM is currently evaluating the effect of four different polymer formulations on water temperature.

Natural productivity, oxygen and water quality

Supplemental aeration to each of CENAIM’s 0.25-ha greenhouse-earthen ponds was provided through an 8-hp paddlewheel aerator. The systems operated continuously throughout the production cycle.

The effectiveness of aeration management on dissolved oxygen levels could not be established because primary productivity levels were relatively high, as evidenced by the diurnal cycles of dissolved oxygen occluding the external aeration supplement. An apparent negative effect of plastic cover or elevated water temperatures on natural productivity in the greenhouse structures was therefore not evident. Oxygen levels below 3 milligram per liter were rare, and almost never dropped below 2 milligrams per liter. Total ammonia levels were relatively low and always below 1.2 milligram per liter.

Production results

Production results showed a strong correlation between shrimp density and final yield (Fig. 2). Stocking densities in the nursery phases varied 16 to 275 postlarvae per square meter, reaching productions of 748 to 5,255 kilogram per hectare, while yields in the grow-out phase (8 to 10 weeks after transference) ranged 1,113 to 5,900 kilogram per hectare with stocking densities of 25 to 84 shrimp per square meter. Final survivals in both production phases were independent of shrimp densities. Average shrimp growth was 0.8 grams per week.

Conclusion

The value of greenhouse production was evidenced when shrimp in surrounding open ponds were continuously affected by WSSV mortality outbreaks at different levels of intensity, while those in greenhouse ponds were not.

Greenhouse structures maintained water temperatures 3 to 5 degrees-C above open pond temperatures. Greenhouse pond water reached temperatures of 29 to 32 degrees C during the colder July-November season, which may still pose a risk for WSSV outbreaks. Although only 60 to 70 percent of visible light passed through the greenhouse plastic film used, it did not affect natural primary productivity.

Production levels were density-dependent, while survivals were not. Production up to 5,900 kilogram per hectare was achieved in the greenhouse-earthen pond structures.

(Editor’s Note: This article was originally published in the February 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Stanislaus Sonnenholzner, Ph.D.

Scientific Coordinator

Centro Nacional de Acuicultura e Investigaciones Marinas

Escuela Superior Politécnica del Litoral

Campus Politécnico

P. O. Box 09-01-4519

Guayaquil, Ecuador[99,101,46,117,100,101,46,108,111,112,115,101,46,109,105,97,110,101,99,64,110,101,110,110,111,115,115]

-

Jorge Calderón, Ph.D.

General Director

Centro Nacional de Acuicultura e Investigaciones Marinas

Escuela Superior Politécnica del Litoral

Campus Politécnico

P. O. Box 09-01-4519

Guayaquil, Ecuador

Tagged With

Related Posts

Health & Welfare

Alphavirus replicon particles potential method for WSSV vaccination of white shrimp

A study demonstrated that VP19 and VP28 white spot syndrome virus envelope proteins expressed by replicon particles provided protection against mortality due to WSSV in shrimp.

Health & Welfare

CENIACUA develops WSSV-resistant shrimp in Colombia

To combat white spot syndrome virus (WSSV) in white shrimp, Corporación Centro de Investigación de la Acuacultura de Colombia (CENIACUA) initiated a selective-breeding program to develop resistance in shrimp.

Health & Welfare

A comprehensive look at the Proficiency Test for farmed shrimp

The University of Arizona Aquaculture Pathology Laboratory has carried out the Proficiency Test (PT) since 2005, with 300-plus diagnostic laboratories participating while improving their capabilities in the diagnosis of several shrimp pathogens.

Responsibility

A look at various intensive shrimp farming systems in Asia

The impact of diseases led some Asian shrimp farming countries to develop biofloc and recirculation aquaculture system (RAS) production technologies. Treating incoming water for culture operations and wastewater treatment are biosecurity measures for disease prevention and control.