Safety measures an extension of good aquaculture practices

Until now, hazard analysis critical control point (HACCP) systems for managing and documenting processes to assure food safety have been the responsibility of food processors, not producers of raw food materials. The world view of raw ingredients, though, has changed tremendously over the last few years.

Consumers are worried about genetically modified organisms, antibiotic residues, mad cow disease, and more. All of these elements are controlled by food producers, not processors.

Seafood buyers and consumers increasingly want the same kinds of assurance from shrimp farms they get with HACCP at packing plants – and the most efficient way to give it to them is by implementing HACCP at the production level.

HACCP benefits

Although they require effort to implement, HACCP plans bring the benefits of quality assurance, documented chain of custody, documented monitoring and inputs, and better supervision of employee actions. For farmers who actively carry out good aquaculture practices (GAP) programs, HACCP requires little more than some redirected consideration of farm production steps, along with monitoring, documentation, and some verification analyses.

Since HACCP is a food safety assurance methodology, shrimp farmers must focus their attention on those aspects of production that are considered risks to consumer heath and welfare. HACCP programs do not address social, environmental, or shrimp health issues, and this simplifies tremendously the tasks of monitoring and verifying that are inherent in all HACCP systems.

The Global Aquaculture Alliance and Aquaculture Certification Council, Inc. websites, as well as many international publications, have much information available on management practices that assure food safety. These practices are based on an evaluation of hazards that might occur during production on a shrimp farm and cannot be controlled by further processing. HACCP is a formalized and more detailed extension of these practices.

Implementing HACCP programs at shrimp farms requires a firm commitment from farm managers and involvement with all levels of farm employees from general managers to kitchen staff. Implementation begins with a HACCP team of representatives of all branches of farm management, from technical to maintenance to kitchen supervision. This engenders a feeling of ownership in all farm sectors and is important to assure actual compliance.

Program development

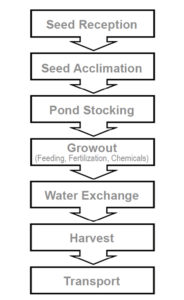

Once a farm HACCP team has been established, development of a HACCP program begins with a definition of all the production steps taken on the farm. These are organized into a flow chart, which is the reference point for determining at what point food safety hazards can enter the production chain.

Determining hazards and how they might occur is called hazard analysis. Much of this type of work has already been done, with the information available online at the websites of the United States Food and Drug Administration and the European Community.

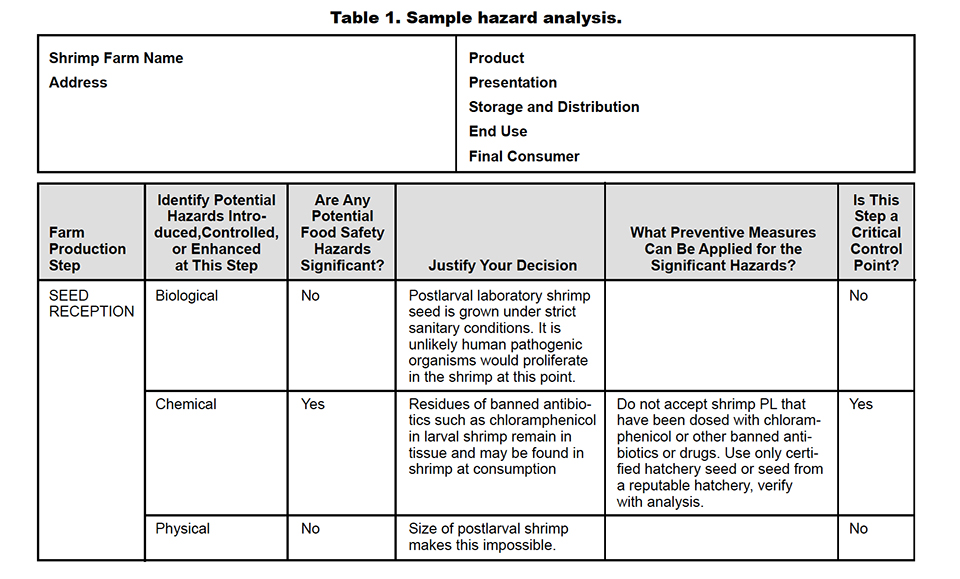

For farms, most potential hazards are either chemical, such as the presence of prohibited antibiotics or high levels of pesticide in farm-raised shrimp, or biological, as with the presence of Salmonella sp. See Table 1 for an example of a hazard analysis carried out for one step of a shrimp production flow chart.

It is important for farm HACCP teams to differentiate between potential hazards that occur as part of production (stocking, grow-out) and those that are part of GAP programs (pest control or sewage/waste control). This is why flow charts are important – at this point, the HACCP team is only considering actual production steps, not the overall actions taken on farms to maintain a clean, pest-free environment.

Actions

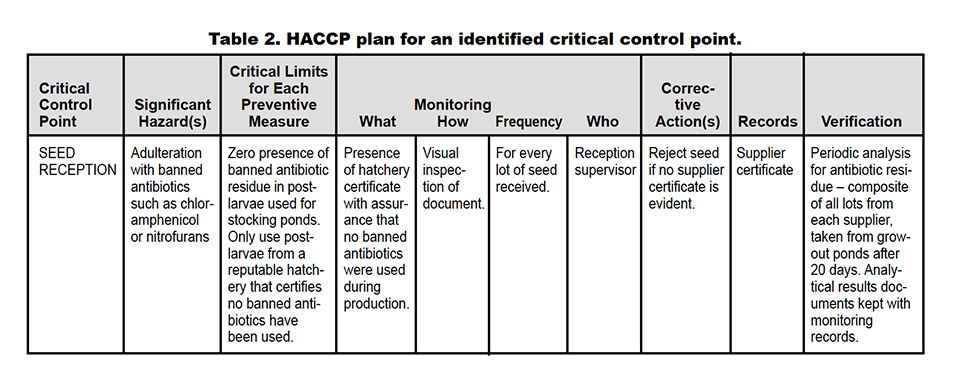

Once the hazard analysis is completed for every critical step in the flow chart, the farm HACCP team must establish critical limits for each critical control point and procedures for monitoring, corrective actions, record keeping, and verification.

Critical limits

A critical limit is a point beyond which either the product is not acceptable or action must be taken to bring the product within acceptable tolerances. Reasonable limits allow farmers to either prevent hazards or provide opportunities to mitigate risks during production.

Monitoring procedures

Monitoring procedures are vital at this point. The HACCP team must identify procedures and documentation that confirm the preventative measures or critical controls are actually carried out.

Monitoring should be easy and cost-efficient, and depends on both the preventative measures and monitoring frequencies involved. These can be different for every critical limit, and may include analysis or simple visual examination. The HACCP team must also identify who will monitor the preventative measures.

Corrective actions

For times when a critical limit is surpassed during production, the HACCP team should develop corrective actions to bring the shrimp back within acceptable limits. Corrective actions are like fire drills – they detail actions to be taken and who should take them, so no time is lost when trouble comes.

Record keeping

Record keeping provides proof that shrimp farms carry out all the procedures of their HACCP plans. Records should be continual, systematic, and include chain of custody information on who provided the seed, feed, and other inputs. Records should also prove that all the monitoring procedures detailed in the HACCP plan are implemented.

Verification

The final part of a HACCP plan, verification, is just as important as all the others. Verification usually includes occasional analysis of farm inputs, as well as shrimp in the ponds. Verification analyses should be frequent enough to give farmers confidence in their procedures and suppliers. They should also be documented as part of the HACCP plan. See Table 2 for an example of a completed HACCP plan for one critical control point.

If the environment in which a process takes place is contaminated, all the process controls implemented are worthless. Filth, pests, and chemical contamination must be controlled as part of GAP programs, with such actions monitored and documented. Effective HACCP implementation on shrimp farms depends on GAPs relating to food safety and their accurate documentation.

Such procedures may sound complicated, but in reality, good farm managers maintain very complete records of feed, seed, and chemical suppliers; stocking dates and quantities; water quality; antibiotic use; and more. Reorganizing this documentation for HACCP records is usually all that is necessary in terms of record keeping.

Farmers may have to analyze more samples of feed and product to verify supplier declarations, but this is an important self-protective measure that shows commitment to consumer safety and could also save thousands of dollars should a product be rejected due to contamination from a supplied input.

Conclusion

Farm-level HACCP requirements are currently only a discussion point, but the trend is toward obligatory documentation at all levels of production and processing. Forward-thinking shrimp farm managers would do well to begin preparing now. Shrimp farms will probably soon need HACCP plans to meet importing regulations in the United States and Europe.

(Editor’s Note: This article was originally published in the August 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Monica Drazba

Aquaculture Certification Council, Inc. Certifier

Mirador de Sto. Domingo #84

Managua, Nicaragua

Tagged With

Related Posts

Responsibility

Beyond HACCP: Total procedures manuals, Part 1

Seafood processors must increasingly codify all procedures, not just those related to food safety and hazard analysis critical control point (HACCP).

Intelligence

Food safety, quality control in tilapia products

The most important quality issue for tilapia is the presence of off-flavors that derive from cyanobacteria and actinomycetes, which can be addressed by depuration.

Health & Welfare

Seafood allergies: Varied responses deserve attention

Seafood allergies result in symptoms like hay fever, nausea, vomiting, diarrhea, hives and asthma but some individuals experience severe and occasionally fatal anaphylactic reactions.

Innovation & Investment

The lasting legacy of Bill and Betty More

The husband-and-wife team of Bill and Betty More has earned admiration and respect in many parts of the world for their many decades of work in aquaculture and sustainability certification. SIRF has established a living memorial in their name.