Waddell Mariculture Center develops, applies biosecurity protocols

The aquaculture industry is under increasing scrutiny and regulation. In response, aquaculture producers must proactively identify potential risks associated with their operations. An approach that integrates risk assessment, management, and communication is necessary to minimize unintended consequences.

Hazard analysis critical control point

Hazard analysis critical control point (HACCP) management is an effective preventive risk management system that is increasingly being used in the aquaculture industry. Critical limits, maximum and/or minimum values, are set at each critical control point (CCP) of the system. A CCP is defined as a step at which control must be applied to prevent, eliminate, or reduce a hazard to an acceptable level. When real-time monitoring of CCP reveals that critical limits are being violated, specific corrective actions are taken to bring the system back into compliance.

A specific hazard analysis is then performed on the system to evaluate the next steps. Once the cause of the violation is determined, a predetermined short-term fix is immediately implemented. A long-term solution is also identified and scheduled for implementation. These activities are documented through corrective-action reports that include the deposition of all noncomplying items.

Positive results

The Food and Agricultural Organization (FAO) and World Health Organization (WHO) recommended that the HACCP concept be applied to freshwater aquaculture programs in Asia to control foodborne digenetic trematode infections in humans. The results in Vietnam showed that the application of HACCP principles to silver carp culture was effective in preventing and controlling the human intestinal parasite Clonorchis sinensis. Similarly, the application of these principles to aquaculture ponds in Thailand and Laos to control parasitic Opisthorcis viverrini infections was also successful.

HACCP team

HACCP is a two-step process. The first step is to assemble a HACCP team consisting of people with specific knowledge and expertise of the operation. The team describes the system, distribution, and intended use of the items it produces. Next, the team develops a flow diagram that describes the operation, followed by on-site verification of the flow diagram.

HACCP principles

The second step requires the team to apply the seven HACCP principles:

- Perform systematic hazard analysis.

- Determine critical control points.

- Establish critical limits.

- Determine appropriate corrective actions.

- Establish monitoring procedures.

- Establish verification procedures.

- Establish record-keeping systems.

HACCP for aquaculture

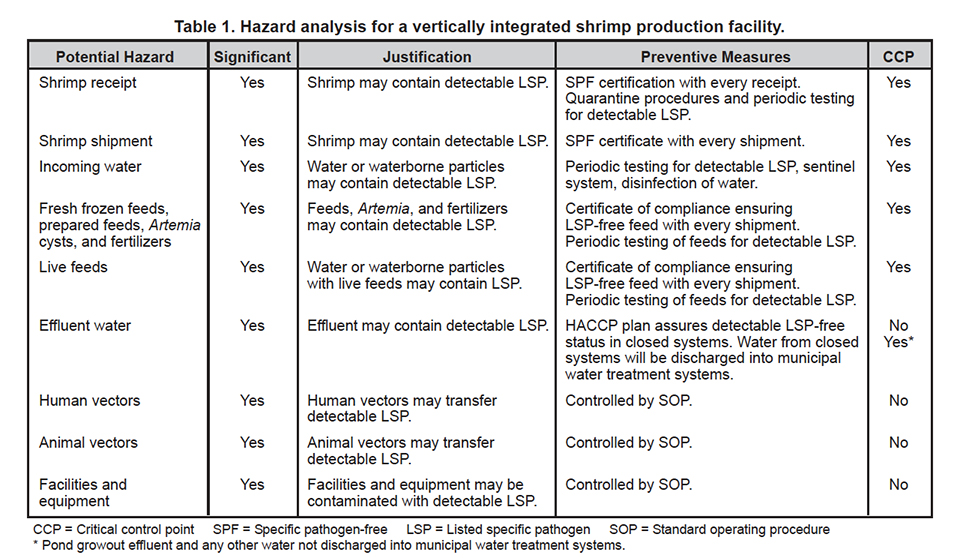

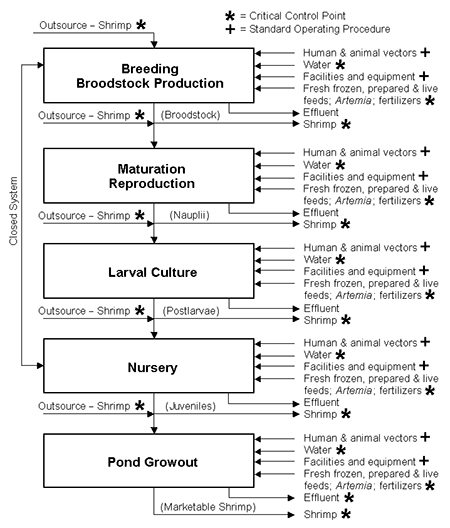

In work reported by the main author in 2001/2002, HACCP principles were applied as a risk management tool to control viral pathogens at shrimp aquaculture production sites and a shrimp-processing facility. Table 1 shows the hazard analysis for a shrimp aquaculture facility. The operational flow diagram is shown in Fig. 1.

At each operational step and CCP, hazards were identified and assessed, control measures and critical limits were established and monitoring procedures and record-keeping requirements were identified. Outsourced live shrimp receipt, shrimp shipment of live and finished product, feed receipt, and incoming water were identified as CCP, as well as effluent water at the pond grow-out step.

Preventive methods and measures

Preventive methods to control listed specific pathogens (LSP) ensure the receipt and production of LSP-free shrimp, water and feed. If LSP are detected, treatments must be applied.

Preventive measures to control the detectable LSP hazards associated with employees, animals, and equipment focus on developing and implementing employee-training programs, following good agricultural practices, and developing written, detailed standard operating procedures.

Flow diagram

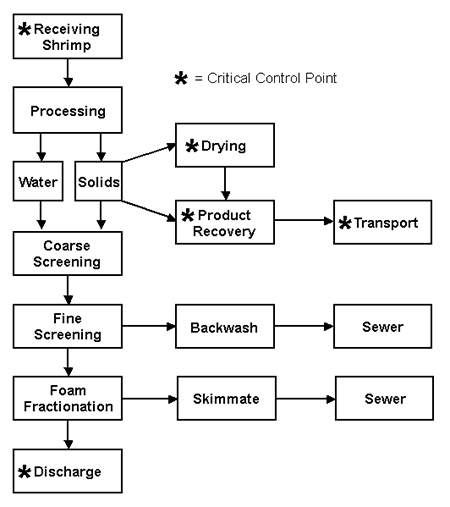

An abbreviated flow diagram for a shrimp-processing facility is shown in Fig. 2. Critical control points include shrimp receipt, protein solids recovery, transport of processing solids, treatment of processing solids, and wastewater discharge.

Measures to prevent, eliminate, or reduce hazards to acceptable levels are:

- Review receiving records to determine origin of shrimp.

- Treat solid wastes on site or transport wastes in a leakproof container to a treatment facility.

- Ensure adequate heating during dehydration of solids for LSP inactivation.

- Discharge effluents into a municipal sewage treatment system.

- Filter and foam fractionate effluents to reduce total solid concentrations and detectable LSP concentrations.

Additional required support

This is not a stand-alone management program. The successful application of HACCP principles as a management program requires additional support information. The following is a partial listing of additional required support information.

- General information needed from a facility that provides eggs, shrimp, or live feeds: biosecurity protocols; list of aquatic species held at the facility and any confirmed disease outbreaks associated with them; disease surveillance testing results; analytical testing results for disease outbreaks; written protocols for facility disinfection for disease outbreaks within the past two years; documentation and protocols used to destroy eggs, shrimp, or live feeds following any disease outbreak; analytical laboratory data to verify specific pathogen-free status of eggs, shrimp, or live feeds.

- Source history required for eggs, shrimp, and live feeds includes: geographic information on the locations where eggs, shrimp, or live feeds originated; all documented disease occurrences in the areas where they were harvested, reared, or hatched. If the eggs, shrimp, or live feeds were held at an intermediate location during harvest and transport, information must be included that describes the holding site.

- Information required for prepared diets includes: documentation of the processing procedures and temperatures used to prepare the diets; written standard operating procedures for employee and facility sanitation protocols at the feed mill.

- General analytical testing laboratory requirements include: confirmation that the laboratory is qualified to conduct the analyses; confirmation that laboratory personnel are proficient with the analytical tests; confirmation that the laboratory uses appropriate methods, has sufficient equipment and proper facilities, and is accredited to conduct the analyses.

- Written standard operating procedures at the production site are required to address disease monitoring and testing protocols, water treatment protocols, and pond and facility disinfection and monitoring protocols.

- The production facility must also follow good agricultural practices and have written procedures that address employee-training policies; equipment use, storage, cleaning, and disinfection protocols; building access controls, facility cleaning and disinfection protocols; and general standard operating procedures that address facility maintenance protocols.

Current applications in aquaculture

The development, implementation and ongoing enforcement of site-specific health management and biosecurity protocols are essential for the long-term financial and operational sustainability of shrimp-framing enterprises. In that regard, biosecurity protocols have been developed and applied at the Waddell Mariculture Center in South Carolina, USA based upon the application of HACCP principles. In addition, the application of HACCP principles as a risk management tool has also been used to develop a biosecurity program for a nonnative oyster hatchery.

Conclusion

The application of HACCP principles provides a logical approach to identify and control animal and environmental hazards associated with aquaculture production and processing facilities. This management approach emphasizes process control and concentrates on points in the operation that are critical to human, animal, and environmental safety.

Note: A report describing the application of HACCP principles to control viral pathogens at shrimp aquaculture facilities is available from the main author.

(Editor’s Note: This article was originally published in the October 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

Michael L. Jahncke, Ph.D.

Virginia Seafood Agricultural Research and Extension Center

Virginia Tech VA Sea Grant Program

102 South King Street

Hampton, Virginia 23669 USA -

Michael H. Schwarz, M.S.

Virginia Seafood Agricultural Research and Extension Center

Virginia Tech VA Sea Grant Program

102 South King Street

Hampton, Virginia 23669 USA -

Craig L. Browdy, Ph.D.

Marine Resources Research Institute

South Carolina Department of Natural Resources

Charleston, South Carolina, USA -

Al Segars, DVM

South Carolina Department of Natural Resources

Waddell Mariculture Center

Bluffton, South Carolina USA -

Alvin D. Stokes, M.S

South Carolina Department of Natural Resources

Waddell Mariculture Center

Bluffton, South Carolina USA -

Juan L. Silva, Ph.D.

Mississippi State University

Department of Food Science & Technology

Mississippi State, Mississippi, USA -

David C. Smith, M.S.

Clemson University

Department of Food Science and Human Nutrition

Beaufort, South Carolina USA

Tagged With

Related Posts

Intelligence

4-hexylresorcinol: sulfite-free control for melanosis in crustaceans

4-hexylresorcinol in a nonsulfite processing treatment against melanosis in crustaceans inhibits natural enzymes for shell hardening.

Responsibility

Certification programs for aquafeed manufacturing

Private aquafeed certification standards have been developed to bring trust and demonstrate responsible industry practices among aquafeed manufacturing stakeholders.

Health & Welfare

Biosecurity practices on fish farms need beefing up

Biosecurity measures and preventive strategies are essential in any biological production chain. Properly planned and implemented biosecurity programs will enhance animal health, production and economics.

Responsibility

Addressing safety in Latin America’s tilapia supply chain

Over the last decade, the experience gained by many tilapia farmers combined with proficient programs implemented by local governments have significantly improved tilapia production in various Latin American countries like Colombia, Mexico, Ecuador and other important tilapia producers in the region.