How much of the water that you heat finds its way back to the heat exchanger?

There is much talk these days about efficiency, sustainability and being “green.” Aquaculture is in some cases a very energy-intensive endeavor. Water is not cheap to pump, filter or heat. One of the most effective ways to reduce heating bills is through heat recovery, which is simply taking heat energy from system effluent and using it to heat the influent.

I can still remember back to my days as an engineering student learning the principle of the countercurrent-flow flat-plate heat exchanger. Surprisingly, it was presented in a Fish Physiology course while covering fish respiration. Exactly the same principle applies – in the respiration case, countercurrent-flow exchange of oxygen, and in the heat exchanger case, countercurrent-flow exchange of heat energy.

Intuitively, one would think that in trying to heat a volume of water starting at 5 degrees with a like volume of water starting at 10 degrees, the highest possible resulting temperature is 7.5 degrees. Fortunately, that is not the case when the counter-flow principle is applied.

Upon close examination of fish respiration, it has been determined that fish gills are designed to provide a flow of deoxygenated blood in a direction opposite that of the oxygenated water flow. The purpose: to maintain a concentration gradient to facilitate oxygen diffusion into the blood.

Example

Suppose a coldwater fish is in an environment where the oxygen level is 10 ppm. Also, suppose the deoxygenated blood coming back to its gills has a partial pressure equivalent to 5 ppm of oxygen in the water. Oxygen always flows from a higher pressure to a lower pressure passively. Cocurrent flow would dictate a resulting 7.5 ppm in both the blood and water. However, using countercurrent flow, a much greater exchange takes place.

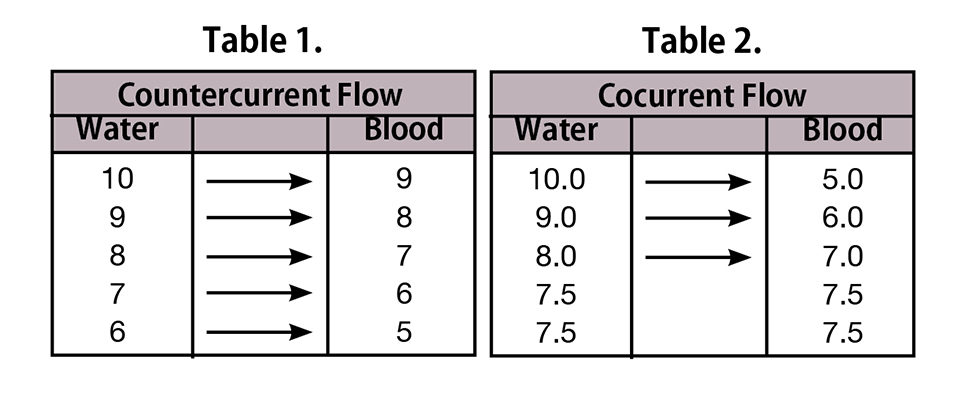

Consider Tables 1 and 2, imagining the water flowing down both tables and the blood flowing up in the first and down in the second. By using countercurrent flow, which requires the same amount of effort as cocurrent flow, the resulting transfer of oxygen is nearly double!

Now imagine that instead of fish respiration, we are discussing heating water from 5 to 10 degrees. Instead of water and blood, think effluent and influent. Since heat transfer also happens passively when a temperature gradient is present, the same tables apply. Again, nearly twice the amount of heat is transferred with the same amount of effort.

Bottom line implications

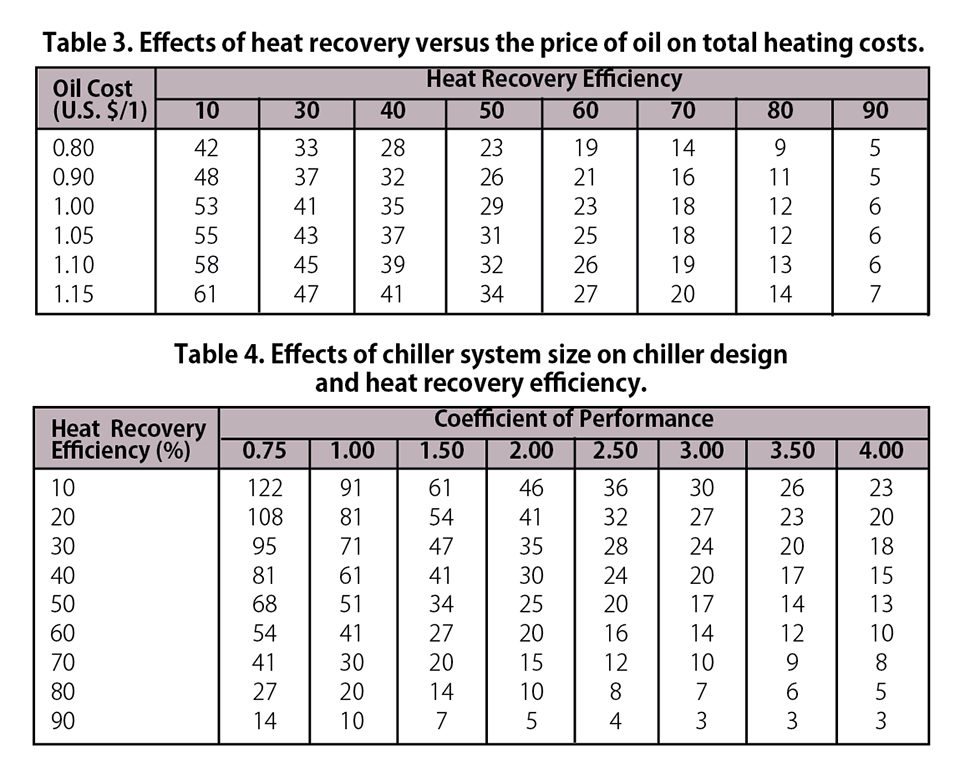

This principle can have very big implications to the bottom line at facilities that heat or cool water. The author recently produced Table 3 for a farm to show the effects of heat recovery versus the effects of the price of oil on the total heating bill.

Every year, with the current oil-fired boiler system in place and all else equal, this farm spends $5,000 to $61,000 on oil. Farms have virtually no control over the cost of oil, but the good news is that it has less of an effect than heat recovery practices.

Using Table 3, compare the costs of cocurrent flow and countercurrent flow, assuming both are 80 percent efficient. At $0.80 per liter, they are $28,000 and 9,000, respectively. That is a 3:1 ratio, not the 2:1 you would expect looking only at the achievable temperatures.

Now for anyone already using a countercurrent exchanger, what does this table mean? Consider your whole system. How much of the water that you heat finds its way back to the heat exchanger? 100 percent? 90 percent? Think of the filters you use. Where do their drains go? What about daily practices such as purging drains? How about head tanks and sumps – if they have overflow drains, where does that water go? It all quietly adds up to a big heating bill if left unchecked.

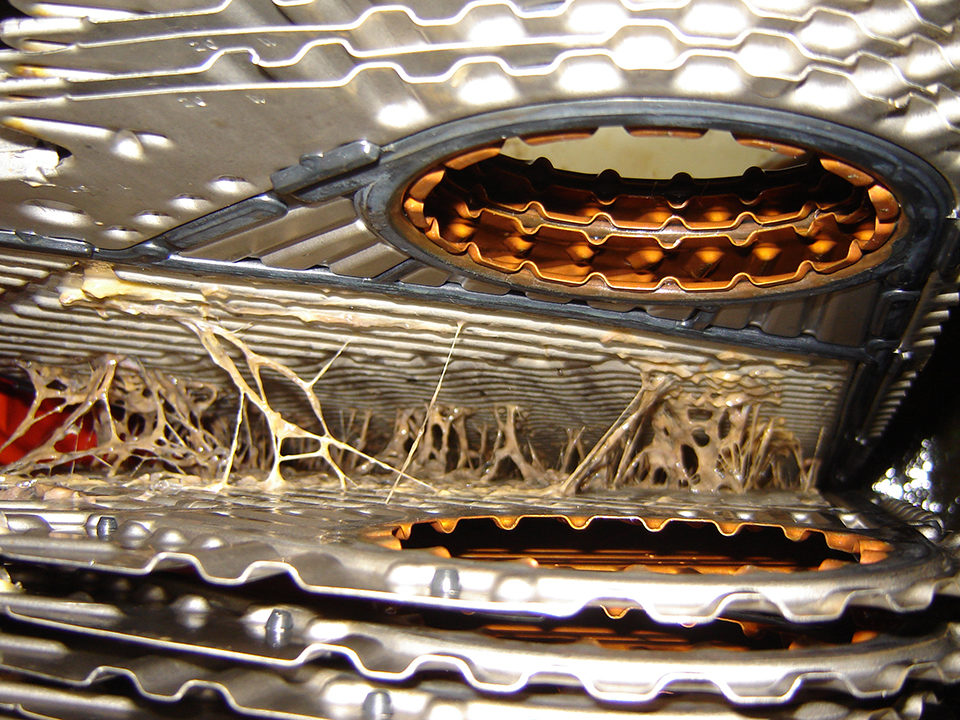

Fouling

Another common occurrence is the fouling of heat exchangers. Suppose you can direct every drop of water back to the heat exchanger. What is the heat exchanger’s efficiency? A clean, properly sized exchanger should perform at greater than 90 percent efficiency. However, exchangers can get so fouled they operate at near-zero efficiency. Based on the data table, the resulting heating bill was 10 times what it could have been.

Chiller systems

Table 4 is another table made for the same farm and same system. This one shows how the size of chiller system needed can be affected by the chiller design versus the heat recovery efficiency.

Chilling water in aquaculture is rarely done well. Suffice it to say that the coefficient of performance (COP) should never be less than 4. Going back to the table, again it is clear that heat recovery efficiency has a much larger impact on required horsepower than COP.

Suppose a facility has a very poor COP of 1. Would it be better to buy a 14-hp system or 122-hp? Consider the electricity bill to run the two systems. Clearly, effort (and maybe money) spent on increasing the heat recovery efficiency of a system will save both capital and operational costs.

Recommendations

Here are some tips for getting the most out of your water-heating dollars.

Always, always heat recover. Always keep the heat exchanger clean, even if it means backwashing every day and taking it apart weekly. All heated water must make its way back to the heat exchanger. If maintaining different temperatures, it may be beneficial to heat recover water of different temperature separately.

Use level sensors with variable-frequency drives or shutoff controls in all head tanks and sumps rather than overflow drains to prevent losing heated water from the system.

Measure the water temperature of the effluent leaving the heat exchanger to determine the efficiency of heat recovery. Use this as a baseline to make improvements to the system. Once you are satisfied with the heat recovery, then, and only then, does it make sense to look at heating and/or cooling equipment with a critical eye toward increasing efficiency.

(Editor’s Note: This article was originally published in the January/February 2009 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Philip Nickerson, P.E.

Technical Manager

Scotian Halibut Ltd.

P. O. Box 119

Clark’s Harbour

Nova Scotia B0W 1P0, Canada

Related Posts

Health & Welfare

Asepsis key to prevent contamination in shrimp hatcheries

Maintaining biosecurity and asepsis in larval shrimp production is a key component of the production chain in Ecuador, which requires the production of 5.5 billion larvae monthly from 300-plus hatcheries.

Intelligence

Byproduct utilization for increased profitability, part 4

Protein hydrolysates can be produced by acid, base or enzymatic hydrolysis processes. Acid hydrolysis produces salt that makes the product unsuitable for food and destroys some essential amino acids. An optimum process for one fish or shellfish by-product may not be optimum for another.

Health & Welfare

Development of 1-monoglycerides against AHPND

1-monoglycerides are known for their antibacterial and antiviral effects in the human pharmaceutical and animal husbandry industries. As a substitution for the preventive use of antibiotics, these molecules are being evaluated in the fight against AHPND.

Health & Welfare

ELISA kits offer quantitative analysis of trifluralin in fish

Antibody-based enzyme-linked immunosorbent assay (ELISA) tests are proven, sensitive, high-throughput alternatives to more costly and complex test methods for the detection of herbicide residues and other chemicals.