As described in this column in the February 2003 Global Aquaculture Advocate, high hydrostatic pressure (HHP) processing can improve the shelf life, quality, and safety of fish and fishery products. Among other impacts, high pressures either destroy or inactivate harmful microbial cells in the fish products through a combination of physiological and biochemical effects on the microorganisms. Microorganisms’ responses to HHP, however, vary significantly.

Microorganisms that share the same scientific name can have significantly different biochemical and physical properties. Unlike many other forms of life, microorganisms only have to share a few biochemical and morphological properties to be classified as identical. Consequently, many microorganisms with the same scientific name can have disparate responses when exposed to similar environmental effects. Any processes or procedures designed to control a single microorganism must consider the variations in properties that can occur within that species.

Effects of pressure on Listeria monocytogenes

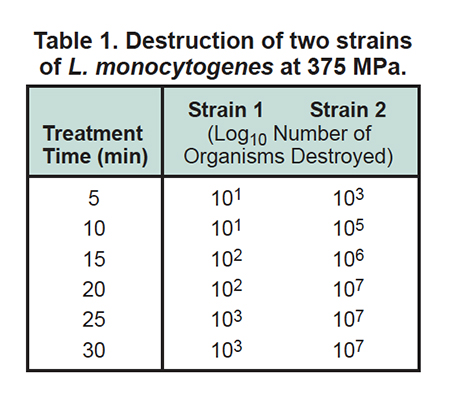

Substantial differences among various L. monocytogenes isolates have been reported in scientific literature. Table 1 provides an example of the magnitude of microbial inactivation that has been reported within two isolates, one obtained from a microbial collection and the other isolated from a food product.

With five minutes of HHP processing at 375 million pascals (MPa), one strain was reduced by a factor of 10, while the other was reduced by a factor of 1,000. The magnitude after 20 minutes of pressurization illustrated an even greater difference in pressure rsistance between the strains. One strain was reduced by a factor of 100, while the other was reduced by a factor of 10 million. A processor developing a process to reduce L. monocytogenes by 5 logs10 could have a process as short as five minutes or longer than 30 minutes, depending on the pressure tolerance of the specific strain of microorganism encountered.

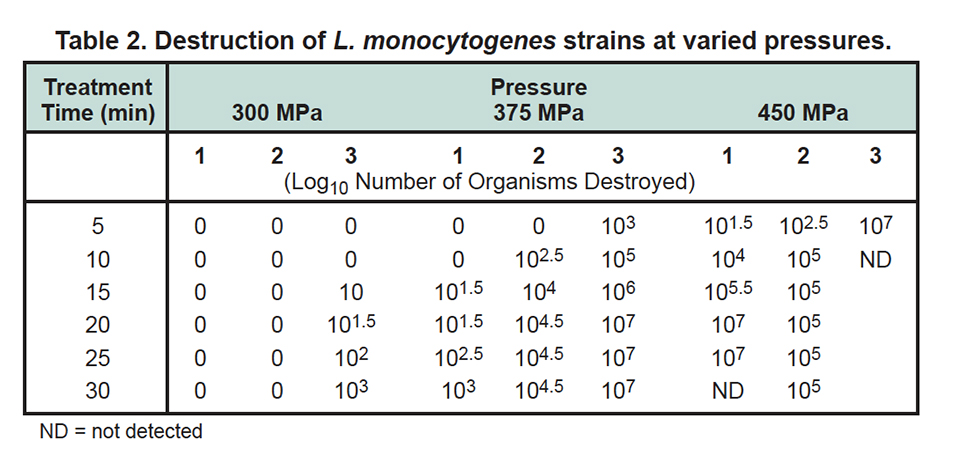

A second study utilizing various pressures and three strains of L. monocytogenes clearly demonstrated the lethal effect of increasing pressure on cells (Table 2). However, a significant difference in pressure resistance was again observed among the three strains.

The time required for microorganism inactivation or death was significantly reduced by increasing the hydrostatic pressures applied. A processor producing a ready-to-eat product and employing reasonable sanitary practices should not have a L. monocytogenes population greater than 1,000 per grams in the final product. Therefore, a listericidal HHP process could be less than 10 minutes at 450 MPa, while at 300 Mpa, the process would exceed 30 minutes.

Effects of pressure in different food products

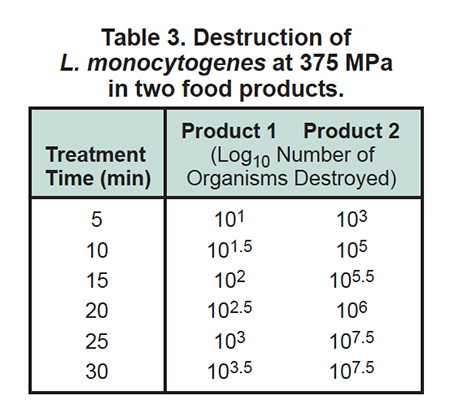

In addition to differences between stains and pressures, the environment in which the microorganisms are contained during pressurization is important. Some products provide a sparing effect on microorganisms, while others increase their vulnerability. Table 3 demonstrates the survival of one strain of L. monocytogenes in two different food products at 375 MPa.

In addition to differences between stains and pressures, the environment in which the microorganisms are contained during pressurization is important. Some products provide a sparing effect on microorganisms, while others increase their vulnerability. Table 3 demonstrates the survival of one strain of L. monocytogenes in two different food products at 375 MPa.

These figures clearly showed that if complete or partial destruction of L. monocytogenes in a food product is desired, research must determine if more than one strain is present and how readily the various strains succumb to pressurization in that food product. Unfortunately, the information obtained on the destruction or inactivation of a microorganism in one food product cannot be readily transferred to another product.

Effects of pressurization ramp on microorganism inactivation

One strain of L. innocua was used as a surrogate microorganism in a study where slow pressurization with rapid depressurization was tested against a process with rapid pressurization and slow depressurization. The test was conducted over a range of 400 to 600 Mpa, with holding times ranging 0.5 to five minutes. Results of the study indicated there was no difference in inactivation of the microorganisms between the two techniques.

Conclusion

When developing a process, the services of a food microbiologist and statistician could prove to be most useful. Since the United States Food and Drug Administration has established a zero defect action level for L. monocytogenes in cooked, ready-to-eat products, processors cannot afford to establish treatment processes that do not perform as intended.

Variables to be considered in developing a listericidal process based on high hydrostatic pressure technology should include the variations in the various L. monocytogenes serovars, magnitude of the reduction required, food product being processed, and intended use of the product. Finally, the sanitary operations of the processing facilities are most important.

A facility that employs acceptable sanitary practices may require a 3 log10 reduction, while one with marginal sanitary practices may need a 5 log10 reduction. The process time required to achieve the two log difference could be significant. Longer process times can result in major increases in capital investments and production costs.

(Editor’s Note: This article was originally published in the April 2003 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

George J. Flick, Jr., Ph.D.

Food Science and Technology Department

Virginia Tech (0418)

Blacksburg, Virginia 24061 USA

Tagged With

Related Posts

Intelligence

All about Listeria

The pathogenic bacterium Listeria monocytogenes is present in the environment and easily transferred to food and food contact surfaces.

Intelligence

An examination of seafood packaging

Some substances can migrate from plastics and other seafood packaging materials into the product. Even if the substances are not harmful, they can affect the flavor and acceptability of the food.

Health & Welfare

Brazil shrimp farm performs genetic selection for IMNV resistance, growth

The Queiroz Galvão Alimentos shrimp farm and hatchery in Brazil have been working with Concepto Azul to implement a disease-prevention and genetic-breeding program that addresses ongoing impacts from infectious myonecrosis virus (IMNV) and other pathogens.

Health & Welfare

High hydrostatic pressure processing has potential

High hydrostatic pressure processing, which got its start over a century ago, is finally reaching the point where it can be commercially applied on a large scale.