Implementation aids operating efficiency, postlarval quality

Progressive hatchery operators have long recognized the benefits of adding benthic pennate diatoms of the genera Amphora and Navicula to their larviculture tanks. The practice began when wild plankton filtrates of 500-μ fraction were added to the culture tanks to stimulate a bloom of naturally occurring flora and fauna.

Frequently, these filtrates produced a luxuriant growth of surface-adhering benthic diatoms. Improved survivals from these tanks prompted the isolation and propagation of the species involved. One operator referred to the practice of adding benthic diatom cultures to culture tanks as “sliming.”

Benthic diatoms and periphyton

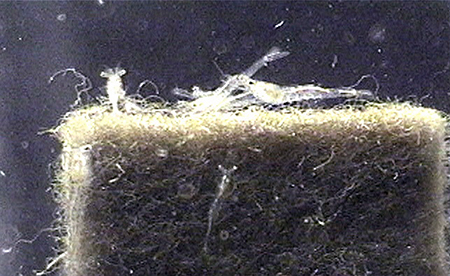

Microscopic examination reveals that benthic diatoms provide the basic matrix for a complex of microorganisms commonly referred to as periphyton. Periphyton include benthic diatoms and associated microfauna (bacteria, rotifers, protozoans, etc.). Nutritional analyses have shown benthic diatoms and the associated periphyton to be rich in highly unsaturated fatty acids and polyunsaturated fatty acids, making periphyton a valuable feed resource for postlarvae.

Concentrated diatoms

The arrival of Taura Syndrome Virus, White Spot Syndrome Virus, and other pathogens, and the resultant strict biosecurity protocols eliminated the practice of using plankton filtrates. Also, the hatchery industry trend to intensify production and lower costs has imposed the need for greater control over the culture environment.

Recognizing the benefits of benthic diatoms, Meridian Aquatic Technology, LLC has been closely involved with several commercial hatcheries and their efforts to test and isolate strains of benthic diatoms. The goal was to select a strain that combines the benefits of a high nutritional profile and ease of use in commercial hatchery environments. This research led to the commercial production of a concentrated product containing pure, live, disease-free Amphora diatoms.

Artificial substrates

Upon metamorphosis, P. vannamei postlarvae begin to exhibit a strong preference for surface grazing, as opposed to the more pelagic behavior associated with larval stages. Often the area provided by culture tank surfaces is not sufficient to support the benthic algae biomass required by the shrimp, and can be completely grazed within three days following metamorphosis.

The use of artificial substrates like AquaMats® provides additional algae growth area of approximately 140 square meters per unit. Also, substrate units can provide about 410 square meters for beneficial bacteria growth. Coating these surfaces with diatoms of high nutrient value satisfies both the behavioral and nutritional requirements of postlarvae. Hatcheries using this combination have successfully increased stocking densities, improved survivals, and reduced or eliminated artemia usage.

Implementation

Taking full advantage of this new understanding of postlarval requirements requires some rethinking of the postlarval production process.

Single-stage production

Traditional postlarvae production is carried out in indoor tanks equipped with aeration and water temperature control systems. For Penaeus vanna-mei, tanks are typically stocked at densities of 50 to 150 nauplii (omega-5) per liter and grown out through metamorphosis until harvest size is reached.

Two-stage production

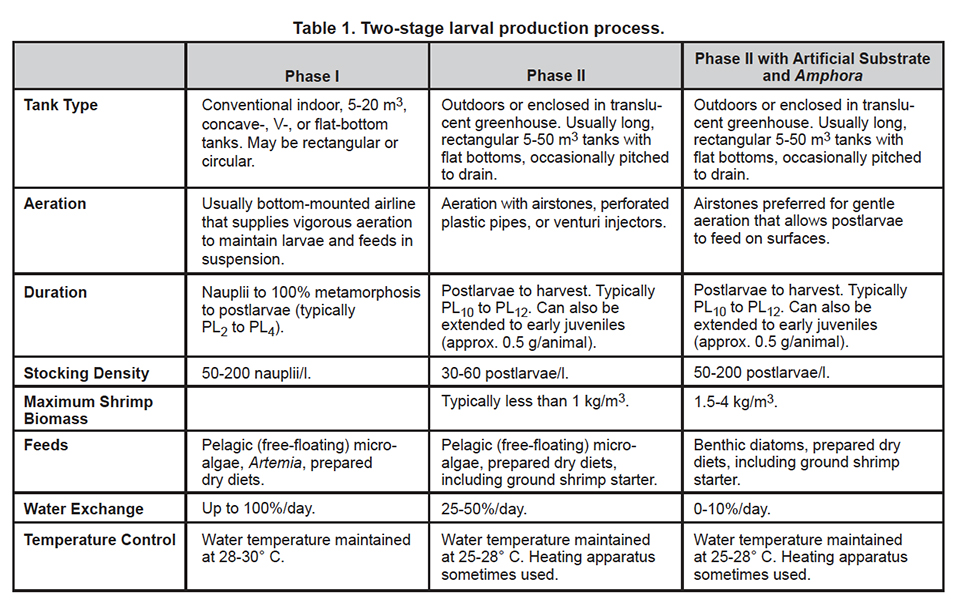

Recognizing the change in shrimp feeding behavior from the pelagic to the more benthic mode has prompted some Western Hemisphere hatcheries to physically separate larviculture into two phases (Table 1). Phase I includes traditional larviculture from nauplii to metamorphosis, while phase II includes postlarvae transfer to different tanks shortly after metamorphosis.

Conclusion

Implementation of artificial substrates with Amphora diatoms in two-phase larviculture systems has produced improvements in both operating efficiency and postlarval quality. Operations have seen increased stocking densities, improved survivals, faster growth, larger average size, improved stress test results, and increased production.

(Editor’s Note: This article was originally published in the February 2002 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

-

Jeffrey J. Peterson

Meridian Aquatic Technology, LLC

4041 Powder Mill Road, Suite 205

Calverton, Maryland 20705 USA[109,111,99,46,115,116,97,109,110,97,105,100,105,114,101,109,64,110,111,115,114,101,116,101,112,106]

Tagged With

Related Posts

Responsibility

A review of water quality improvement products

Prof. Boyd examines products used by aquafarmers to improve water quality and conditions in their ponds and discusses their efficacy.

Intelligence

An emerging shellfish farming industry in Namibia

For shellfish farming in Namibia to continue expanding, industry must better comply with approved sanitation standards. The Namibian Shellfish Monitoring and Sanitation Program, currently in development, will help.

Health & Welfare

Artificial upwelling maintains favorable summer environment for farmed oysters

The summer season poses threats for oyster aquaculture worldwide. In addition to high mortality, poor oyster quality and health – especially in enclosed bays – are often attributed to water stratification, high temperatures and hypoxia.

Health & Welfare

Biofloc technology expanding at white shrimp farms

Biofloc technology provides high productivity, low feed-conversion ratios and a stable culture environment. Also, with viral problems and rising costs for energy, biofloc technology can help deliver sustainable production at lower cost.