Caged fish provide ‘free’ fertilization for cultured fish, reduce nutrient loads

Integrated cage-cum-pond systems reflect an approach to aquaculture where high-value species are stocked in cages suspended in ponds, and filter-feeding species are stocked in open water outside the cages. These systems allow caged fish to be fed high-protein diets, while pond fish derive their nutrition from natural foods generated by cage wastes that function as fertilizer.

Cage-cum-pond systems have several advantages, including the ability to culture fish with controlled feed inputs and good water quality, and production of a simple rotation system that allows growing fish to a larger size while still rearing smaller fish extensively. The systems also provide a reduction in nutrients that would otherwise be discharged from intensive systems.

An ideal integrated system would stock small fish in a pond at a given density with their growth stimulated to normal levels by cage wastes. As the fish reach the carrying capacity of the pond, they are moved to cages and fed to stimulate growth to a larger size, while new stock is introduced to the pond.

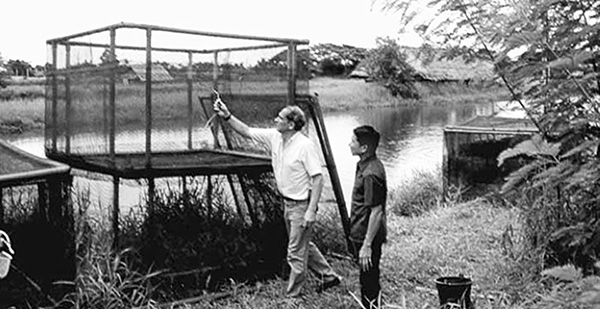

System testing in Thailand

In studies in Thailand sponsored by the Pond Dynamics/Aquaculture Collaborative Research Support Program (CRSP), the authors recently tested various combinations of integrated cage-cum-pond systems, mainly with tilapia in ponds and walking catfish or tilapia in cages. These systems produced high yields of both pond and cage fish with good water quality when managed in balance.

Walking catfish/tilapia experiments

Research using hybrid walking catfish (Clarias macrocephalus x C. gariepinus) in cages and Nile tilapia (Oreochromis niloticus) at large in ponds showed that treatments with 1 to 2 cages per pond produced better results than higher stocking densities. These treatments resulted in net fish yields as high as 56 metric tons (MT) per hectare per year.

The most efficient system in terms of nutrient retention used 1 cage per pond, which delivered 3.7 kg nitrogen and 1.0 kg of phosphorus per hectare per day. This input rate was similar to optimum fertilization levels determined in other CRSP experiments at 4 kg nitrogen and 1 kg phosphorus per hectare per day.

About 48 percent of the added nitrogen was retained in fish with 1 cage per pond, while 2 cages per pond resulted in 34 percent nitrogen retention. Of these totals, the tilapia at large retained 13 percent and 4 percent of the added nitrogen, respectively. For phosphorus, 61 percent and 42 percent were retained in fish, with 17 percent and 5 percent retained in the tilapia, respectively. This aquaculture system reduced the nutrient enrichment of ponds compared to feeding alone and supported a new crop of tilapia raised on fish waste.

Tilapia experiments

A second series of CRSP experiments was conducted using large Nile tilapia in cages with small tilapia in ponds. This experiment had the best results when cages were stocked at 50 fish per cubic meter and the pond at 1.4 fish per cubic meter.

Survival was 98.8 percent for the caged tilapia, which grew from 120 to 456 grams in 90 days with a net annual yield of 18 MT per hectare. The open-pond tilapia grew from 16 to 124 grams, with 92 percent survival and a net annual yield of 6.2 MT per hectare.

The daily waste-loading rate was approximately 1.7 kg nitrogen and 0.37 kg phosphorus per hectare, somewhat lower than the optimal fertilization rate. Caged and pond fish accounted for about 50 percent of the nitrogen applied to the pond and 60 percent of the phosphorus. The pond fish retained 13 percent of the nitrogen and 15 percent of the phosphorus.

Pond dynamics

The dynamics of oxygen, ammonium, and plankton were evaluated against total loading rates for all culture combinations. Oxygen levels declined 75 to 100 percent in all loading rates of the ponds and never approached zero decline. Nitrogen increased with increased loading density of fish. A level of zero change in ammonium occurred at a loading rate of about 0.8 kilograms per cubic meter.

Plankton dynamics showed similar results. A fish loading rate with zero change in chlorophyll a should occur at about 0.3 kilograms per cubic meter. These results indicated it may be possible to reduce nitrogen and plankton contents in effluent water, but doing so would require loading rates that are not economically feasible.

Conclusion

Overall, results from recent experiments supported the use of cages in ponds as an efficient means to fertilize ponds for semi-intensive tilapia growth and reduce the loading of nutrients to discharged water. Also, the production of tilapia outside cages in ponds occurs essentially without cost, as the only nutrient addition is the feed applied for the intensive growth of the caged fish. Overall yields are substantial and can be combined to be efficient even for resource-poor farmers with few ponds.

(Editor’s Note: This article was originally published in the August 2004 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Authors

-

James S. Diana, Ph.D.

School of Natural Resources and Environment

University of Michigan

Ann Arbor, Michigan 48109-1115 USA -

Yang Yi, Ph.D.

Asian Institute of Technology

Pathumthani, Thailand -

C. Kwei Lin, Ph.D.

Asian Institute of Technology

Pathumthani, Thailand

Tagged With

Related Posts

Innovation & Investment

Aquaculture insurance and reinsurance

As aquaculture grows, the industry will need tailored insurance solutions that address the realities of varied production methods and locations.

Health & Welfare

Walking catfish production in Thailand

The excellent culture characteristics of hybrid walking catfish have made them the dominant culture type in Thailand.

Health & Welfare

Amino acid supplementation reduces protein levels in pangasius diets

Trials show that supplementation with amino acids could reduce protein levels from a typical 28 percent to 23 percent in pangasius diets.

Responsibility

Organic prawn farming comes to India’s rice fields

Expansion of the India Organic Aquaculture Project is leading to organic freshwater prawn culture according to standards developed by Naturland Germany and Indocert.