NFI files petitions seeking FDA approval to use irradiation for molluscan shellfish, crustaceans

Consumer advocates and government agencies are keeping seafood safety concerns before the media and consumers. As a result, food pathogens like Listeria, Salmonella, Vibrio and E. coli (both the harmful and harmless strains) are becoming familiar topics. It is not that these bugs are more prevalent, it is simply that science is advancing at an accelerating rate, enabling seafood processors and regulators to detect pathogens easer and more accurately.

Testing has advanced far beyond growing bacteria in Petri dishes, and new technologies can be applied during processing and handling, rather than after products are in the marketplace or an outbreak of illness occurs.

As testing becomes more sensitive, rapid and cost-effective, seafood producers and processors will be challenged by customers and regulators to find equally effective ways of controlling and destroying seafood pathogens before they can cause harm.

Evaluating irradiation

With the United States Food and Drug Administration (FDA) and the media bearing down on seafood pathogens, and today’s demand for highquality convenience foods, the National Fisheries Institute (NFI) Technical Committee is evaluating the effectiveness of irradiation in combination with other processing methods designed to enhance the safety and quality of seafood products or extend their shelf life.

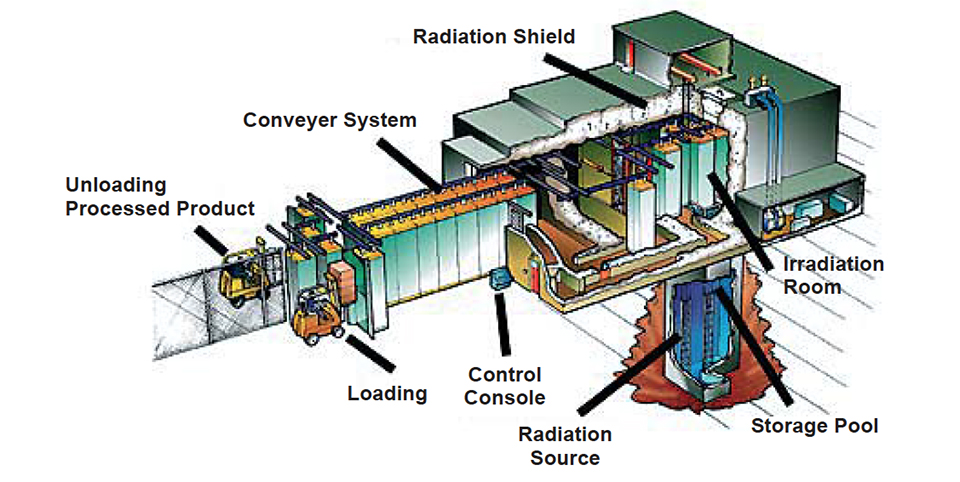

Irradiation is the process of exposing food to controlled levels of ionizing radiation, killing microorganisms without significant changes in texture, flavor or nutritional value (with a few exceptions in the fruit and vegetable category). NFI has filed two petitions seeking FDA approval to use irradiation for molluscan shellfish and crustaceans, and is considering additional petitions for other seafood products.

Technology endorsement

The American Medical Association, World Health Organization, American Dietetic Association, and U.S. Centers for Disease Control and Prevention have all endorsed irradiation as a highly effective weapon in the fight for food safety. The NFI agrees and recently adopted this policy:

“The NFI strongly supports irradiation as one among many useful food safety tools. Irradiation is a safe, effective means of destroying many types of potentially harmful bacteria. The safety and effectiveness of irradiation as a process to eliminate harmful bacteria and destroy pests in food has been proven by innumerable scientific studies. Scientific studies have also shown that the food does not become radioactive. The NFI believes the FDA should regulate the use of irradiation as a food manufacturing process and not under food additive regulations as is currently the case.”

Approved by U.S. FDA

The FDA has studied food irradiation for over 40 years, and repeatedly given it a stamp of approval. Irradiation has been approved for use on wheat, potatoes, spices, pork, fruits, vegetables, and, most recently, red meat and fresh shell eggs. FDA’s endorsements came only after intense scrutiny and a lengthy battery of carefully conducted scientific tests.

In a recent nationwide study conducted by NFI and Diversified Communications, half the consumers surveyed said irradiation would not affect their confidence; about a third said it would decrease their confidence. The largest purchasers of irradiated products, health-care and food-service providers, recognize the added safety of irradiation, both in terms of protecting the health of patients and patrons, and reducing liability in the event of an outbreak of food-borne illness.

Food scientists and technical experts support the use of irradiation and other intriguing new technologies. What is technically feasible, however, is not always useful from a practical standpoint.

While a recent U.S. General Accounting Office report supports the use of irradiation as an effective foodsafety measure, it also recognizes consumers’ reluctance to purchase irradiated foods based on fears of radioactivity or toxic byproducts of irradiation. Consumer groups use these unfounded fears to promote their own food-safety agendas, and try to convince policymakers that irradiation is a cover-up for sloppy food handling.

Conclusion

It is up to everyone in the seafood chain – growers, processors, distributors, retailers, and food-service operators – to ensure irradiation is an addition to, not a substitute for, good handling practices. Given the challenges we will face in the future, firms must assess whether there is more they can do to improve the quality and safety of their products.

Food Irradiation Is… broadly defined as energy moving through space in invisible waves. Radiant energy has differing wavelengths and degrees of power. Light, infrared heat, and microwaves are forms of radiant energy. So are the waves that bring radio and television broadcasts into our homes.

Broiling and toasting use low-level radiant energy to cook food. Ionizing radiation, also known as irradiation, is the radiation of interest in food preservation. These shorter wavelengths can damage microorganisms such as those that contaminate food or cause food spoilage and deterioration. Because much of our food supply is lost due to spoilage and insects, scientists have been experimenting with irradiation as a method of food preservation since 1950, and have determined irradiation to be a controlled and very predictable process.

Irradiation Process… Irradiation is known as a cold process, because it does not significantly increase the te perature or change the physical or sensory characteristics of most foods. During irradiation, the energy waves affect unwanted organisms but are not retained in the food item.

Applications… Because the irradiation process works with both large and small quantities, it has a wide range of potential uses. It is most useful in the preservation and sterilization of food; in the control of sprouting, ripening and insect damage; and in the control foodborne illness. Irradiation can be used to effectively eliminate many pathogens that cause foodborne illness.

Nutritional Quality of Irradiated Foods… Scientists believe irradiation produces no greater nutrient loss than what occurs in other processing methods, such as canning. Ionizing radiation can cause some loss of nutrients, but far less than what results when foods are cooked. In addition, nutrients are naturally lost when foods are stored. Nutrition experts have stated that eating irradiated foods will not cause people to suffer from nutritional deficiencies.

(Editor’s Note: This article was originally published in the February 2001 print edition of the Global Aquaculture Advocate.)

Now that you've finished reading the article ...

… we hope you’ll consider supporting our mission to document the evolution of the global aquaculture industry and share our vast network of contributors’ expansive knowledge every week.

By becoming a Global Seafood Alliance member, you’re ensuring that all of the pre-competitive work we do through member benefits, resources and events can continue. Individual membership costs just $50 a year. GSA individual and corporate members receive complimentary access to a series of GOAL virtual events beginning in April. Join now.

Not a GSA member? Join us.

Author

Tagged With

Related Posts

Aquafeeds

Gamma irradiation enhances nutritional value of animal byproducts

Gamma irradiation treatment presents a possible processing technique for reducing anti-nutrients and improving the nutritive quality of many feed ingredients.

Aquafeeds

Antinutrients in plant-derived fish feed ingredients

An important limiting factor to the inclusion of some vegetable ingredients in aquafeeds is the presence of toxic secondary compounds, or antinutrients, in the ingredients.

Intelligence

Aquaculture 2019: Triennial meeting examines global industry status

The triennial Aquaculture 2019 meeting – which also celebrated the 50thanniversary of the World Aquaculture Society – featured all segments of the aquaculture value chain during 104 technical sessions.

Health & Welfare

Biofilter inoculation in recirculating aquaculture systems

Biological filters are essential parts of recirculating aquaculture systems that transform toxic fish compounds such as ammonium and nitrite into less-harmful nitrate. The authors tested the convenience and efficiency of three methods for the initial inoculation of aerobic biofilters.